1,2-propanediol antifreezing cooling liquid

A technology of antifreeze coolant and propylene glycol, applied in the field of anhydrous 1, can solve the problems of prone to electrochemistry, corrosion, etc., achieve excellent low temperature performance, and eliminate the effect of lining pitting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare 1000kg of a long-term car antifreeze used in areas where the lowest temperature is lower than -50°C:

[0027] Put 800kg of 1,2-propanediol into the reaction kettle, keep the temperature in the kettle not exceeding 80°C, then add 1.5kg of benzotriazole, stir and dissolve for 10 minutes, add 10kg of sebacic acid, 5kg of succinic acid, add 1 kg of hydrolyzed polymaleic anhydride, 4.5 g of defoaming agent, 32 g of acid green dye, and 15 g of tartrazine were mixed evenly, and then the remaining propylene glycol was added to the reaction kettle, and a light green transparent solution was finally formed after stirring for 4 hours. After passing through the filter of 0.5 ~ 1μm, it can be packaged.

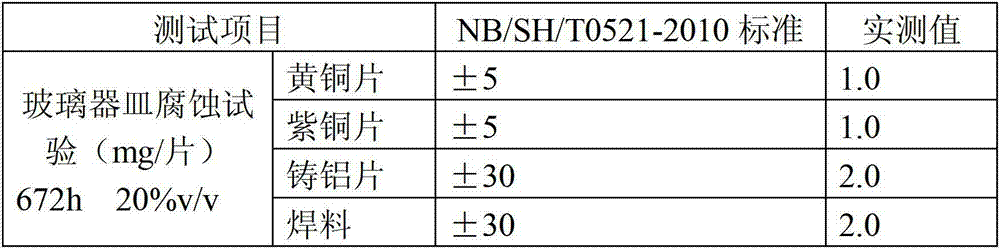

[0028] The specific parameters of the glassware corrosion test are as follows:

[0029]

[0030]

Embodiment 2

[0032] Prepare 1000kg of antifreeze coolant for high-power heavy-duty construction machinery:

[0033] Put 800kg of 1,2-propanediol into the reaction kettle, keep the temperature in the kettle not exceeding 80°C, then add 3kg of benzotriazole, stir and dissolve for 10 minutes, add 18kg of sebacic acid, 9kg of succinic acid, add hydrolysis 1.4kg of polymaleic anhydride, 4.5g of defoaming agent, 32g of acid green dye, and 15g of tartrazine were mixed evenly, and then the remaining propylene glycol was added to the reaction kettle, and a light green transparent solution was finally formed after stirring for 5 hours. After passing through the filter of 0.5 ~ 1μm, it can be packaged.

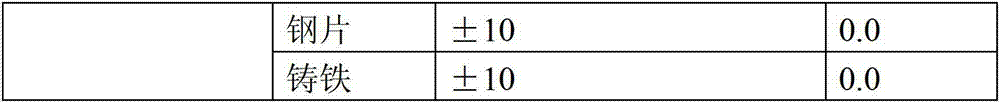

[0034] The specific parameters of the glassware corrosion test are as follows:

[0035]

[0036] Note: the test conditions detected in the above-mentioned Example 1 and Example 2 are more severe, and the test conditions of 336h 33% volume specified in the standard are changed to the more stringen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com