Organic-silicon modified acrylic acid resin superhydrophilic antifogging coating and preparation method thereof

An acrylic resin and anti-fog coating technology, applied in the fields of coating, climate sustainability, sustainable manufacturing/processing, etc., can solve the problem of coating stability and limited number of repeated use, inability to achieve ultra-low temperature anti-fog, complex preparation process, etc. problem, to achieve the effect of excellent anti-fog performance, strong adhesion and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

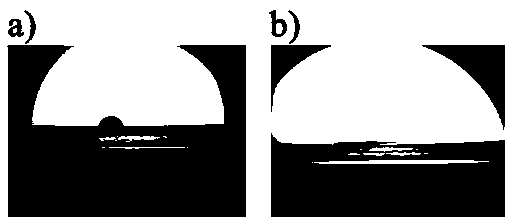

Image

Examples

Embodiment 1

[0052] The pretreatment primer was 0.05g polyvinyl butyral with 20g absolute ethanol. In a clean environment, the cleaned polycarbonate plexiglass surface is coated with a primer and dried at 80°C for 30 minutes. 4.26g of diethanolamine and 5.76g of glycidyl methacrylate were reacted at 60°C for 3h to obtain solution A. Add 10g of DMF as a solvent, then add methyl methacrylate, butyl acrylate, and γ-methacryloxypropyltrimethoxysilane in a molar ratio of 3:1:2 (4.05g, 1.73g, 6.7g) Put it into a three-necked flask, add 0.04g AIBN, react at 60°C for about 1 hour, add 5.27g hydroxyethyl methacrylate, 2.8g 2-acrylamido-2-methylpropanesulfonic acid, finally add A solution, add the remaining Below 0.05g AIBN. The reaction temperature was 60°C, and the reaction was carried out for 4 hours to prepare the coating. After coating on the PC board, the adhesion of the test coating can reach ISO level 0, the coating is transparent and free of air bubbles and shrinkage, it can achieve anti...

Embodiment 2

[0055]The pretreatment primer was 0.05g polyvinyl butyral with 20g absolute ethanol. In a clean environment, the cleaned polycarbonate plexiglass surface is coated with a primer and dried at 80°C for 30 minutes. Add 4.26g of diethanolamine and 5.76g of glycidyl methacrylate into the flask, and react at 60°C for 3h to obtain solution A. Add 10g of DMF as a solvent, then add methyl methacrylate, butyl acrylate, γ-methacryloxypropyltrimethoxysilane according to the mole ratio of 3mol:1mol:2mol (4.05g, 1.73g, 6.7g) Add 0.04g AIBN to a three-necked flask, react at 60°C for about 1 hour, add 1.76g hydroxyethyl methacrylate, 2.8g 2-acrylamido-2-methylpropanesulfonic acid, and finally add solution A, add The remaining 0.05g AIBN. Keep the temperature at 60°C and react for 4 hours to prepare the coating. After being coated on the PC board, the adhesion of the test paint can reach ISO level 0, the coating is transparent, severe shrinkage in some areas, shrinkage around the PC board, ...

Embodiment 3

[0057] The pretreatment primer was 0.05g polyvinyl butyral with 20g absolute ethanol. In a clean environment, the cleaned polycarbonate plexiglass surface is coated with a primer and dried at 80°C for 30 minutes. Add 4.26g of diethanolamine and 5.76g of glycidyl methacrylate into the flask, and react at 60°C for 3h to obtain solution A. Add 10g of DMF as a solvent, then add methyl methacrylate, butyl acrylate, γ-methacryloxypropyltrimethoxysilane according to the mole ratio of 3mol:1mol:1mol (4.05g, 1.73g, 3.35g) Add 0.04g AIBN to a three-necked flask, react at 60°C for about 1 hour, add 1.76g hydroxyethyl methacrylate, 2.8g 2-acrylamido-2-methylpropanesulfonic acid, and finally add solution A, add The remaining 0.05g AIBN. Keep the temperature at 60°C and react for 4 hours to prepare the coating. After being coated on the PC board, the adhesion of the test paint can reach ISO level 0, the coating is transparent, the coating has a large area of shrinkage, the shrinkage ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com