Method for manufacturing high-refractive index TiO2/organic silicon hybrid coating

A technology with high refractive index and manufacturing method, applied in the field of organic-inorganic hybrid coating materials, can solve the problems of increasing the difference of the refractive index of titanium dioxide, low refractive index of organic silicon, light scattering of nano-hybrid coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

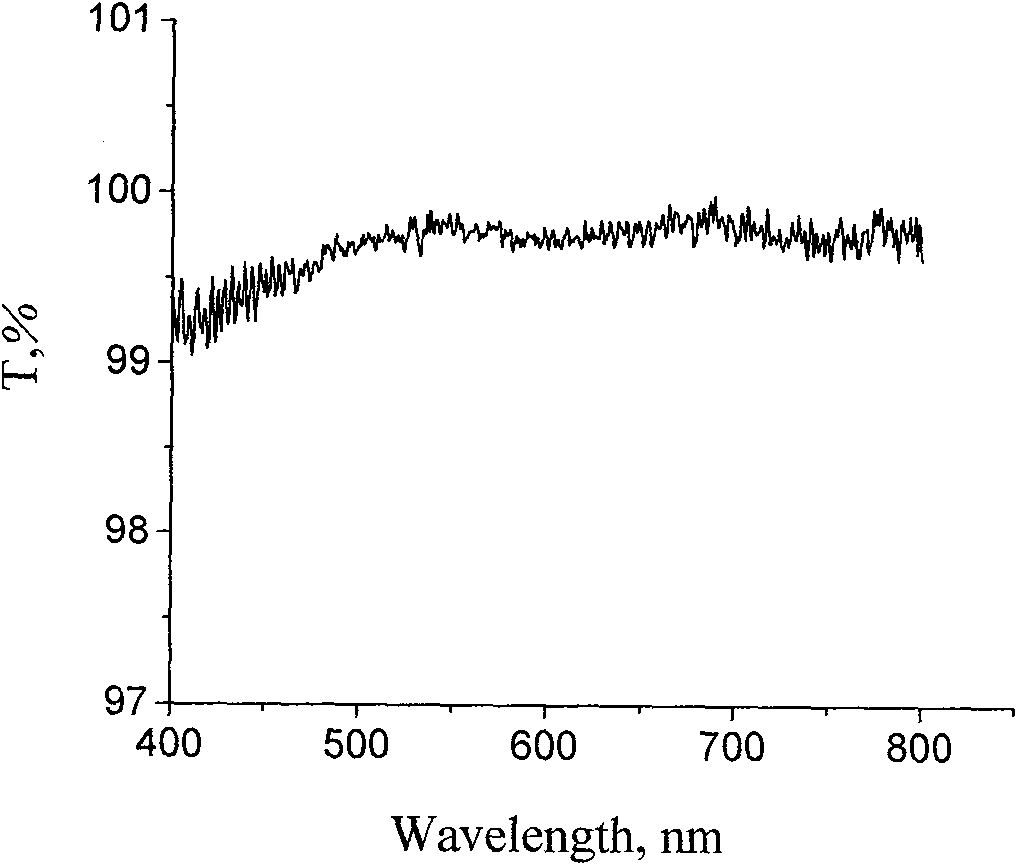

[0022] Put 10g of absolute ethanol, 4.5g of deionized water and 0.1g of concentrated hydrochloric acid in a three-necked flask, magnetically stir and heat to 70°C, slowly add 7.3g of diphenyldimethoxysilane dropwise, and continue to stir and react for 15min, Then 16.5g of KH560 was slowly added dropwise, kept at 70°C and stirred for 2h to obtain a colorless and transparent organosilicon sol (the product was distilled under reduced pressure, and its refractive index was 1.49 measured by Abbe refractometer), stopped heating, and used Add 0.5g of deionized water and 5g of absolute ethanol to the mixed solution of residual heat first, then add 14.7g of butyl titanate dropwise, stir while dripping, and react for 30 hours to obtain transparent nano TiO 2 / Organic silicon hybrid sol. The film was prepared by spin coating (2000rps, 15s), and cured at 100°C for 1h. The refractive index of the coating was 1.54 and the light transmittance was 98%.

Embodiment 2

[0024] Put 10g of absolute ethanol, 4.5g of deionized water and 0.1g of concentrated hydrochloric acid in a three-necked flask, magnetically stir and heat to 70°C, slowly add 8.2g of diphenyldiethoxysilane dropwise, and continue to stir and react for 15min, Then 16.5g of KH560 was slowly added dropwise, kept at 70°C and stirred for 2h to obtain a colorless and transparent organosilicon sol (the product was distilled under reduced pressure, and its refractive index was 1.49 measured by Abbe refractometer), stopped heating, and used Add 0.5g of deionized water and 5g of absolute ethanol to the mixed solution of residual heat, and then add 14.7g of butyl titanate dropwise, stir while adding dropwise, and react for 30 hours to obtain transparent TiO 2 / Organic silicon hybrid sol. The film was prepared by spin coating (2000rps, 15s), and cured at 100°C for 1h. The refractive index of the coating was 1.54 and the light transmittance was 98%.

Embodiment 3

[0026] Put 10g of absolute ethanol, 4.5g of deionized water and 0.2g of acetic acid in a three-necked flask, magnetically stir and heat to 70°C, slowly add 7.3g of diphenyldimethoxysilane dropwise, continue to stir and react for 15min, then Slowly add 16.5g of KH560 dropwise, keep stirring at 70℃ for 2h to obtain a colorless and transparent organosilicon sol, stop heating, use residual heat to first drop 4.3g of deionized water and 15g of absolute ethanol mixed solution, and then dropwise add 80.3g Butyl titanate, stir while dripping, react for 30 hours to obtain transparent TiO 2 / Organic silicon hybrid sol. The film was prepared by spin coating (2000rps, 15s), and cured at 100°C for 1h. The refractive index of the coating was 1.65 and the light transmittance was 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com