SCR (Selective Catalytic Reduction) flue gas denitrification catalyst and preparation method thereof

A denitrification catalyst and flue gas technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as easy deactivation, promote adsorption and activation, combine tightly, and prevent excessive hydrolysis speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

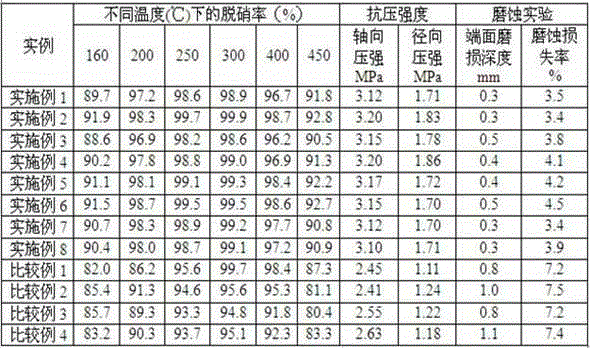

Examples

Embodiment 1

[0029] (1) TiO 2 - Preparation of molecular sieve composite carrier: First, dissolve 4Kg titanium sulfate and 0.2Kg sodium nitrilotriacetate into 2L deionized water to make a mixed solution; add 0.4Kg powdered HZSM-5 molecular sieve to the above mixed solution for equal volume impregnation ;Dried at 80°C for 12 hours; Calcined at 400°C for 5 hours to obtain TiO 2 - Molecular sieve composite carrier.

[0030] (2) Loading of active components and additives: the TiO prepared in step (1) 2 - The molecular sieve composite carrier is impregnated in a mixed solution of 0.2mol / L cerium nitrate, 0.15mol / L ammonium metatungstate and 0.1mol / L ferric nitrate, taken out, dried at 120°C for 6 hours, and calcined at 450°C for 10 hours The denitration catalyst powder is prepared.

[0031] (3) Forming of honeycomb denitration catalyst: 80 parts of denitration catalyst powder prepared in step (2), 6 parts of glass fiber, 0.1 part of softwood pulp, 0.5 part of polyacrylamide, 2 parts of carbo...

Embodiment 2

[0034] (1) TiO 2 -Preparation of molecular sieve composite carrier: first, dissolve 4Kg titanium sulfate and 0.15Kg disodium edetate into 2L deionized water to make a mixed solution; add 0.4Kg powdered HZSM-5 molecular sieve to the above mixed solution for Equal volume impregnation; drying at 120°C for 6 hours; calcination at 500°C for 1 hour to prepare TiO 2 - Molecular sieve composite carrier.

[0035] (2) Loading of active components and additives: the TiO prepared in step (1) 2 - Immerse the molecular sieve composite carrier in a mixed solution of 0.3mol / L cerium nitrate, 0.1mol / L ammonium metatungstate and 0.4 mol / L tin tetrachloride, take it out, dry it at 110°C for 12 hours, and then dry it at 550°C Calcined for 5 hours to prepare denitration catalyst powder.

[0036] (3) Forming of honeycomb denitration catalyst: 90 parts of denitration catalyst powder prepared in step (2), 4 parts of glass fiber, 0.2 part of wood pulp, 1 part of polyacrylamide, 0.5 part of carboxym...

Embodiment 3

[0039] (1) TiO 2 -Preparation of molecular sieve composite carrier: First, dissolve 4Kg titanium sulfate and 0.1Kg tetrasodium edetate in 2L deionized water to make a mixed solution; add 0.8Kg powdered HY molecular sieve to the above mixed solution for equal volume Impregnation; drying at 110°C for 6 hours; calcination at 600°C for 2 hours to obtain TiO 2 - Molecular sieve composite carrier.

[0040] (2) Loading of active components and additives: the TiO prepared in step (1) 2 - Immerse the molecular sieve composite carrier in a mixed solution of 0.2mol / L cerium nitrate, 0.1mol / L ammonium metatungstate and 0.3mol / L copper nitrate, take it out, dry it at 120°C for 6 hours, and bake it at 450°C for 6 hours The denitrification catalyst powder was prepared in hours.

[0041] (3) Forming of honeycomb denitration catalyst: 75 parts of denitration catalyst powder prepared in step (2), 6 parts of glass fiber, 2 parts of wood pulp, 2 parts of polyacrylamide, 0.1 part of carboxymeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com