Two-level copper removing technology for treating low-concentration comprehensive wastewater in PCB electroplating

A comprehensive wastewater, low-concentration technology, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of floating sludge in sedimentation tanks, affecting normal wastewater discharge, etc. The effect of drug cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

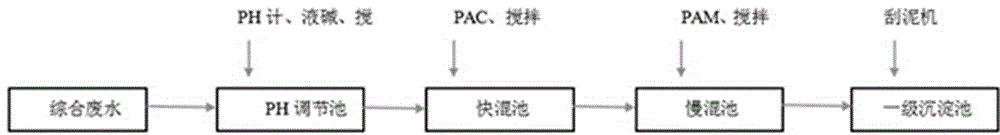

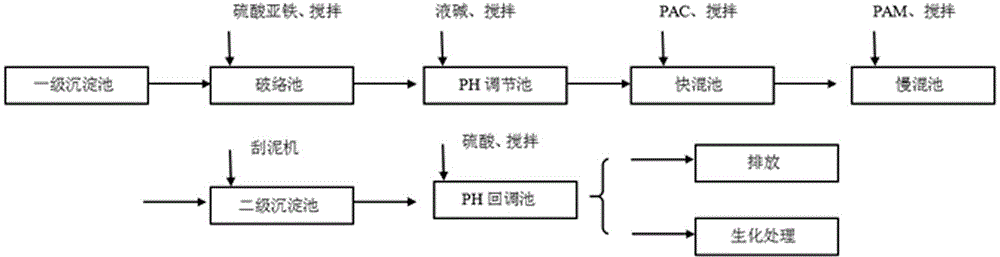

[0027] A secondary copper removal process for treating low-concentration comprehensive wastewater from PCB electroplating, including secondary copper removal processes: the first-level copper removal removes hydrated copper ions in the wastewater, and the second-level copper removal removes complex copper ions. The process includes the following steps:

[0028] (1) The first stage of copper removal: use a lift pump to introduce the comprehensive wastewater into the PH adjustment tank, add liquid caustic soda to the wastewater through the pump and stir evenly with a mixer, adjust the pH to 8.5, use a PH meter for measurement, and then introduce the fast In the mixing tank, add polyaluminum chloride PAC according to the amount of 25kg / 1000 cubic meters of waste water and stir evenly with a mixer, then introduce into the slow mixing tank, add polyacrylamide PAM according to the amount of 2kg / 1000 cubic meters of waste water and stir evenly with a mixer, and then introduce The first-...

Embodiment 2

[0031] A secondary copper removal process for treating low-concentration comprehensive wastewater from PCB electroplating, including secondary copper removal processes: the first-level copper removal removes hydrated copper ions in the wastewater, and the second-level copper removal removes complex copper ions. The process includes the following steps:

[0032] (1) The first stage of copper removal: use a lift pump to introduce the comprehensive wastewater into the PH adjustment tank, add flake caustic soda to the wastewater through the pump and stir evenly with a mixer, adjust the pH to 8.7, use a PH meter for measurement, and then introduce the fast In the mixing tank, add polyaluminum chloride PAC according to the amount of 25kg / 1000 cubic meters of waste water and stir evenly with a mixer, then introduce into the slow mixing tank, add polyacrylamide PAM according to the amount of 2kg / 1000 cubic meters of waste water and stir evenly with a mixer, and then introduce The first-l...

Embodiment 3

[0035] A secondary copper removal process for treating low-concentration comprehensive wastewater from PCB electroplating, including secondary copper removal processes: the first-level copper removal removes hydrated copper ions in the wastewater, and the second-level copper removal removes complex copper ions. The process includes the following steps:

[0036] (1) The first stage of copper removal: use a lift pump to introduce the comprehensive wastewater into the PH adjustment tank, add lime to the wastewater through the pump and stir evenly with a mixer, adjust the pH to 9.0, use a PH meter for measurement, and then introduce fast mixing In the tank, add polyaluminum chloride PAC according to the amount of 25kg / 1000 cubic meters of waste water and stir evenly with a mixer, and then introduce the slow mixing tank, add polyacrylamide PAM according to the amount of 2kg / 1000 cubic meters of waste water and stir evenly with a mixer, and then introduce another Grade sedimentation ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com