Modified fes nanoparticle and its preparation method and application

A nanoparticle and modified technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems such as FeS treatment of Cr that has not yet appeared, and achieve improved storage time and high reactivity. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 0.1-0.5g PVPP to 50ml ultrapure water respectively, and stir for 10 minutes under nitrogen gas to obtain PVPP solution;

[0030] (2) Weigh 2.49gFeCl 2 4H 2 O, dissolved in 12.5ml deoxygenated ultrapure water to obtain FeCl 2 4H 2 O solution, the FeCl 2 4H 2 The O solution was added to the above PVPP solution, and stirred for 10 min under nitrogen to obtain a mixed solution;

[0031] (3) Weigh 3gNa 2 S·9H 2 O, dissolved in 12.5ml deoxygenated ultrapure water to obtain Na 2 S·9H 2 O solution, the Na 2 S·9H 2 The O solution was added dropwise to the above mixed solution, and stirred for 60 min under nitrogen;

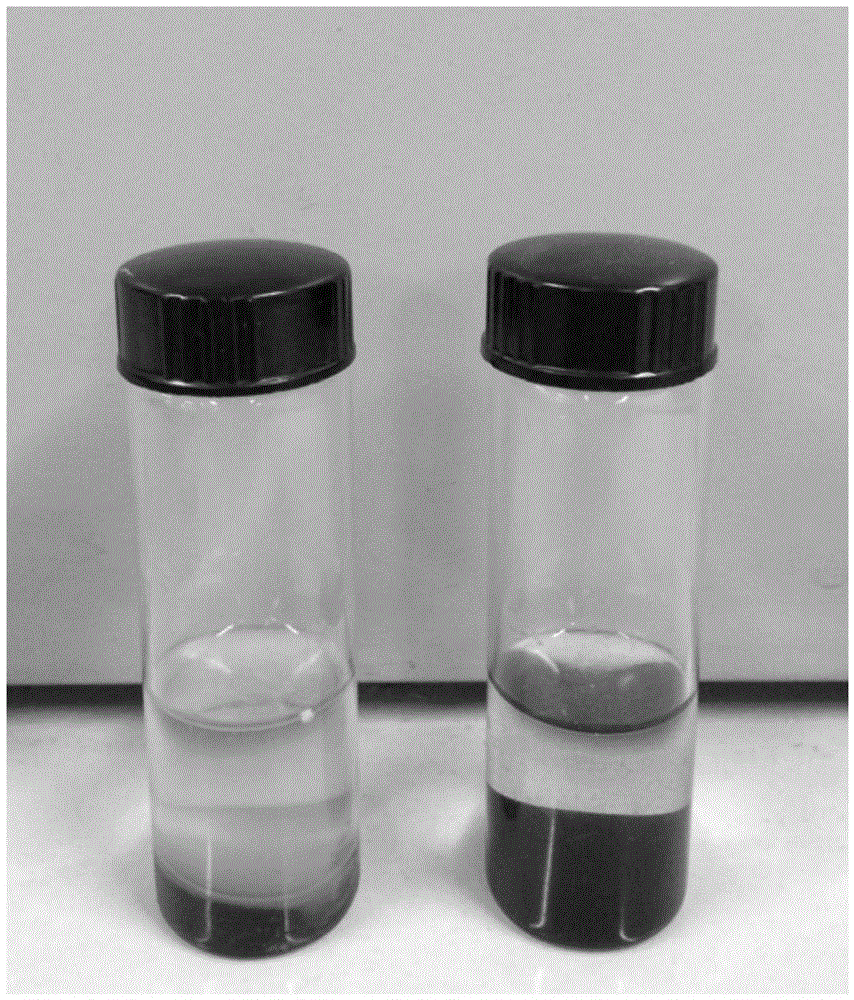

[0032] (4) Then settle naturally, wash 3 times with anaerobic ultrapure water, obtain about 1.2g of FeS-PVPP nanoparticles (i.e. modified FeS nanoparticles), disperse 1.2g of FeS-PVPP nanoparticles in 120ml anaerobic Suspensions of modified FeS nanoparticles were prepared in ultrapure water.

[0033] For the modified FeS nanoparticles prepared a...

Embodiment 2

[0043] (1) Weigh 0.25g of PVPP and add it into 50ml of ultrapure water, and stir for 10min under nitrogen gas to obtain PVPP solution.

[0044] (2) Weigh 2.49gFeCl 2 4H 2 O, dissolved in 12.5ml deoxygenated ultrapure water to obtain FeCl 2 4H 2 O solution, the FeCl 2 4H 2 The O solution was added to the above PVPP solution, and stirred for 10 min under nitrogen to obtain a mixed solution.

[0045] (3) Weigh 3gNa 2 S·9H 2 O, dissolved in 12.5ml deoxygenated ultrapure water to obtain Na 2 S·9H 2 O solution, the Na 2 S·9H 2 The O solution was added dropwise to the above mixed solution, and stirred for 60 min under nitrogen.

[0046] (4) Then settle naturally, wash 3 times with anaerobic ultrapure water, obtain about 1.2g of FeS-PVPP nanoparticles (i.e. modified FeS nanoparticles), disperse 1.2g of FeS-PVPP nanoparticles in 120ml anaerobic Suspensions of modified FeS nanoparticles were prepared in ultrapure water.

[0047] For the modified FeS nanoparticles prepared a...

Embodiment 3

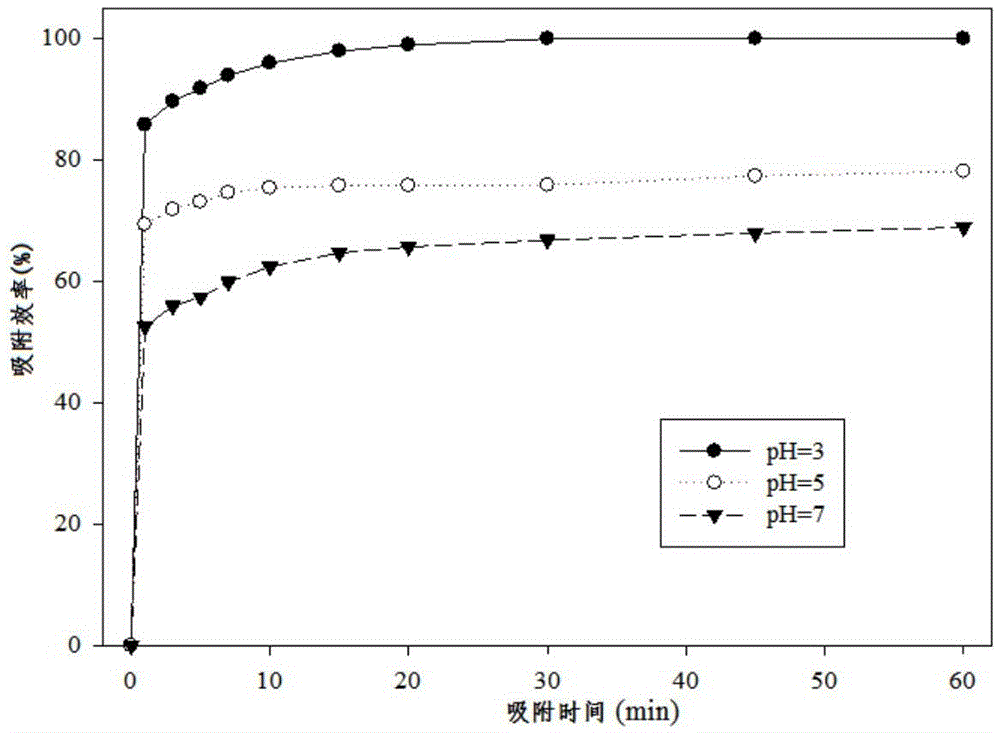

[0049] The modified FeS nanoparticles prepared in Example 2 and the FeS nanoparticles prepared in Comparative Example 1 were respectively treated with chromium-containing wastewater, and the specific operation steps were as follows:

[0050] Preparation of Cr(VI)-containing wastewater: the concentration of chromium-containing wastewater is 10mg / L, 50mg / L, 100mg / L, 200mg / L, 300mg / L, 400mg / L, 500mg / L, and the pH range is 2.8~ 3.1.

[0051] Concentration in 1.0ml embodiment 2 is 1.2g / 120ml modified FeS nanoparticle suspension and the FeS nanoparticle suspension that concentration is 1.1g / 110ml in 1.0ml comparative example 1 is added to above-mentioned different concentrations containing Cr ( VI) In wastewater, carry out constant temperature oscillation treatment at 35°C and 150rpm for 1 hour, then filter with a 0.45 μm filter membrane, take the filtered solution and measure residual Cr(VI) in wastewater by ultraviolet-visible light spectrometer, the results are shown in Table 2 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com