Water treatment device and application thereof

A water treatment device and wastewater treatment technology, which is applied in water/sewage treatment, natural water treatment, animal husbandry wastewater treatment, etc., can solve the problems of high wastewater treatment cost, increase wastewater treatment cost, increase system energy consumption, etc., and achieve saving The effect of energy expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

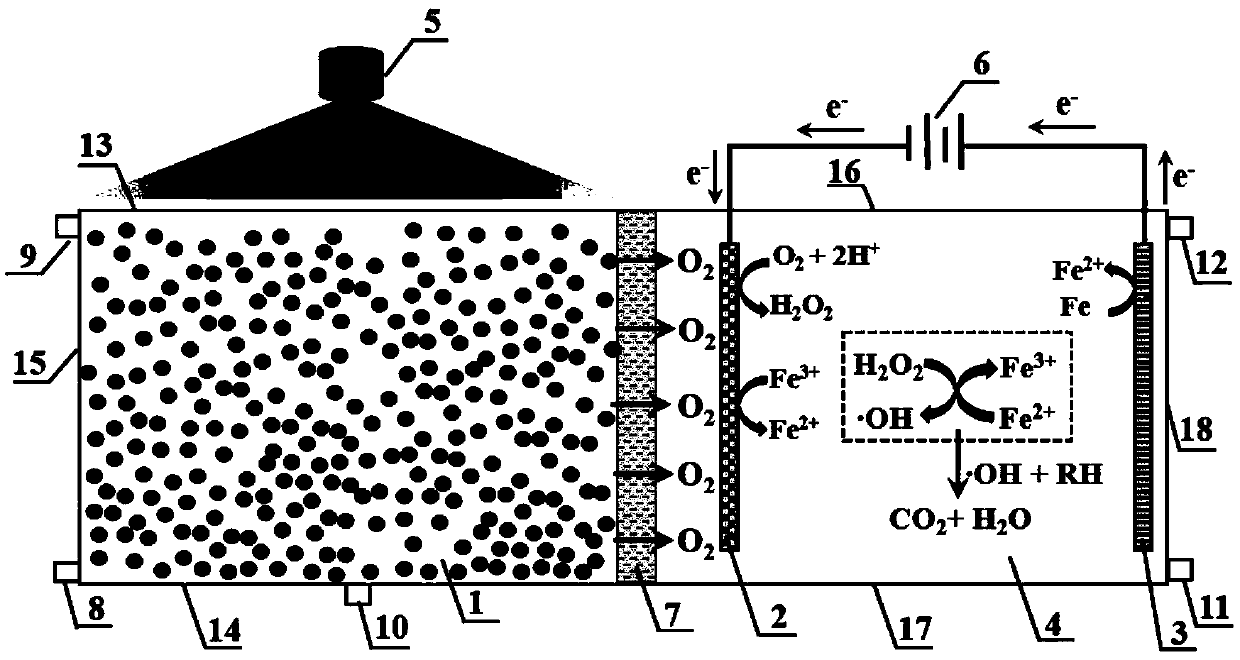

[0122] Specific steps are as follows:

[0123] according to figure 1 , using hydrophobic carbon black-PTFE as the gas diffusion layer, using a 50cm×50cm iron plate as an anode, and a 50cm×50cm graphite plate as a cathode, the working volume of the microalgae growth chamber is 150L (30cm×60cm×60cm). -The volume of the Fenton reaction chamber is 150L (50cm×50cm×60cm), and the distance between the electrodes is 20cm; the gas diffusion layer is fixed between the electro-Fenton reaction chamber and the microalgae cultivation chamber to obtain a water treatment device;

[0124] Pig farm wastewater (COD 2265mg / L, NH 4 + -N 829mg / L, TN 1210mg / L, TP 96mg / L) were continuously pumped into the first water inlet of the microalgae growth chamber, and inoculated with Chlorella vulgaris in the microalgae growth chamber, the inoculation initial concentration was 5×10 6 cell / mL, turn on the light source (consisting of four 8W LED lamp tubes) for light (light-to-dark ratio 12h:12h), Chlorell...

Embodiment 2

[0129] Specific steps are as follows:

[0130] according to figure 1 , with a 0.45 μm hydrophobic nylon filter membrane as the gas diffusion layer, a 50cm×50cm iron plate as the anode, and a 50cm×50cm graphite felt as the cathode, the volume of the microalgae growth chamber is 216L (60cm×60cm×60cm), and the electric -The volume of the Fenton reaction chamber is 72L (60cm×20cm×60cm), and the distance between the electrodes is 10cm; the gas diffusion layer is fixed between the electro-Fenton reaction chamber and the microalgae cultivation chamber to obtain a water treatment device;

[0131] Aquaculture wastewater (COD 87mg / L, NH 4 + -N 7.6mg / L, TN 26mg / L, TP 3.9mg / L) were continuously pumped into the first water inlet of the microalgae growth chamber, and inoculated with Dunaliella salina in the microalgae growth chamber, the inoculation initial concentration was 5×10 5 cell / mL, turn on the light source (consisting of a 38W fluorescent tube) for light (light-to-dark ratio is...

Embodiment 3

[0136] Specific steps are as follows:

[0137] according to figure 1 , with a hydrophobic treated dense stainless steel mesh as the gas diffusion layer, a 40cm×40cm iron mesh as the anode, and a 40cm×40cm graphite felt as the cathode, the volume of the microalgae growth chamber is 125L (50cm×50cm×50cm), and the electric -The volume of the Fenton reaction chamber is 72L (20cm×60cm×60cm), and the distance between the electrodes is 10cm; the gas diffusion layer is fixed between the electro-Fenton reaction chamber and the microalgae cultivation chamber to obtain a water treatment device;

[0138] Aquaculture wastewater (COD 200mg / L, NH 4 + -N 400mg / L, TN 498mg / L, TP 40mg / L) were continuously pumped into the first water inlet of the microalgae growth chamber, and Scenedesmus obliquus was inoculated in the microalgae growth chamber, and the inoculation initial concentration was 5×10 5 cell / mL, turn on the light source (consisting of three 8W LED lamp tubes) for light (light-to-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com