Method for treating waste water in aerobic and two-stage anoxic-aerobic ways

A technology of aerobic treatment and grade anoxic, applied in aerobic and anaerobic process treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve problems such as difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

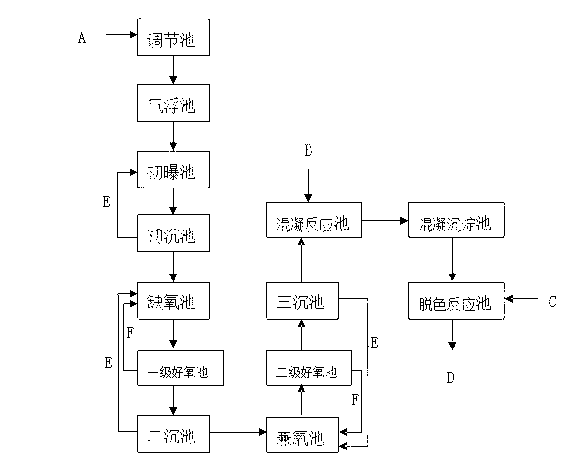

[0020] See attached picture. This example is a pilot test done in a coal chemical plant. The test is a closed test, and non-specific people cannot touch and understand the test process.

[0021] The wastewater passes through the regulating tank, air flotation tank, primary aeration tank, primary sedimentation tank, anoxic tank, primary aerobic tank, secondary sedimentation tank, facultative oxygen tank, secondary aerobic tank, triple sedimentation tank, coagulation reaction tank, The thirteen parts of the coagulation sedimentation tank and the decolorization tank finally meet the standard; among them, the primary settling tank is provided with a sludge return pipeline to the primary aeration tank, and the return ratio is 1:1~2; the secondary settling tank is provided with a sludge return pipeline to anoxic Set the sludge return pipe to the facultative tank in the three sedimentation tank, and the sludge return ratio is 1:1~2; The nitrifying liquid return pipe is set at the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com