Biochemical treatment system and method of waste water through conny pressure gasification

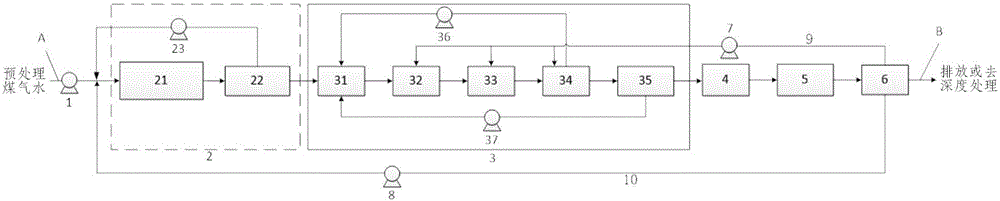

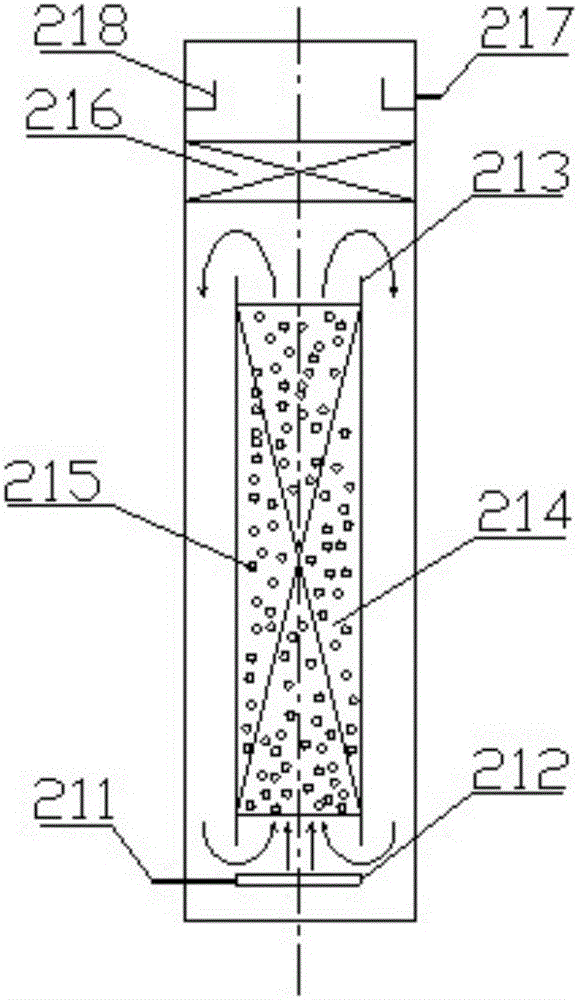

A crushed coal pressurized gasification and biochemical treatment technology, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as poor impact resistance, large water quality fluctuations, and poor biochemical properties , to prevent the loss of the carrier, reduce the concentration of pollutants, and facilitate the effect of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A certain coal gasification wastewater is treated with a crushed coal pressurized gasification wastewater biochemical treatment system, with a treatment capacity of 0.8m 3 / h at a temperature of 35°C. BACB system HRT is about 50h, AO n The HRT of the system is about 300h, the circulation volume of the circulation pump is 800%, the return flow of the mixed liquid is 300%, and the return flow of the return pump is 100%. The influent COD of the biochemical system is about 7000mg / L, and the ammonia nitrogen is about 500mg / L. After being treated by the BACB system, the COD of the effluent is about 190mg / L, and the ammonia nitrogen is lower than 10mg / L, which can meet the "Comprehensive Wastewater Discharge Standard" (GB8978-1996 ) secondary emission standards.

Embodiment 2

[0060] A certain coal gasification wastewater is treated with a crushed coal pressurized gasification wastewater biochemical treatment system, with a treatment capacity of 1.2m 3 / h at a temperature of 35°C. BACB system HRT is about 33h, AO n The HRT of the system is about 200h, the circulation volume of the circulation pump is 600%, the return flow of the mixed liquid is 300%, and the return flow of the return pump is 100%. The COD of the influent water of the biochemical system is about 6700mg / L, and the ammonia nitrogen is about 450mg / L. After being treated by the BACB system, the COD of the effluent is about 270mg / L, and the ammonia nitrogen is lower than 10mg / L. It can be discharged or reused after advanced ozone treatment.

[0061]The biochemical treatment system of the present invention aims at the characteristics of high toxicity, poor biodegradability, and large water quality fluctuations of crushed coal pressurized gasification wastewater, and the problems of conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com