Method for sewage treatment during refined cotton production and odor control in sewage treatment

A production process and technology for refining cotton, applied in separation methods, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of unsatisfactory treatment effect, polluted air environment, and high pharmaceutical costs, and achieve ideal control effects and treatment effects. Good, small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

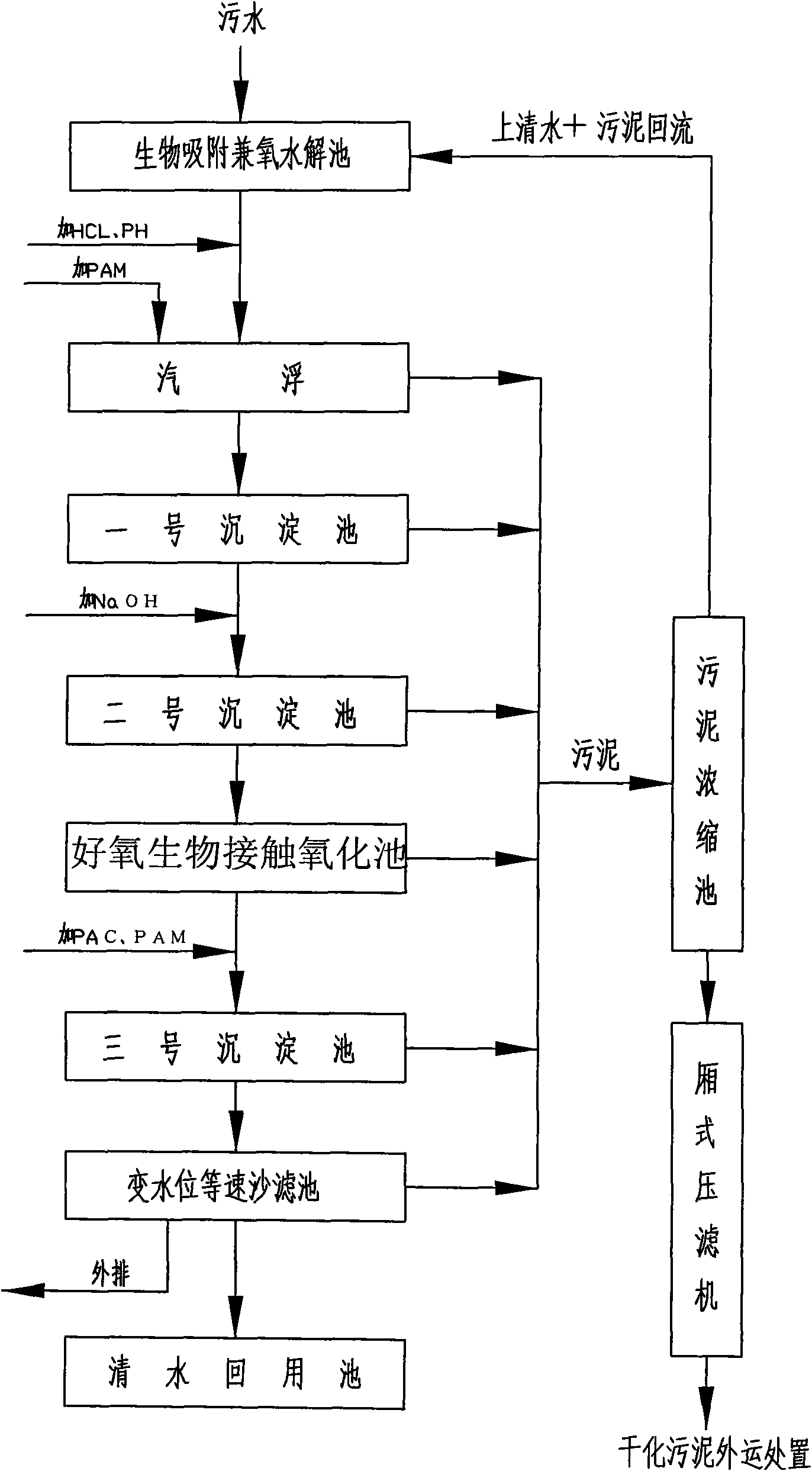

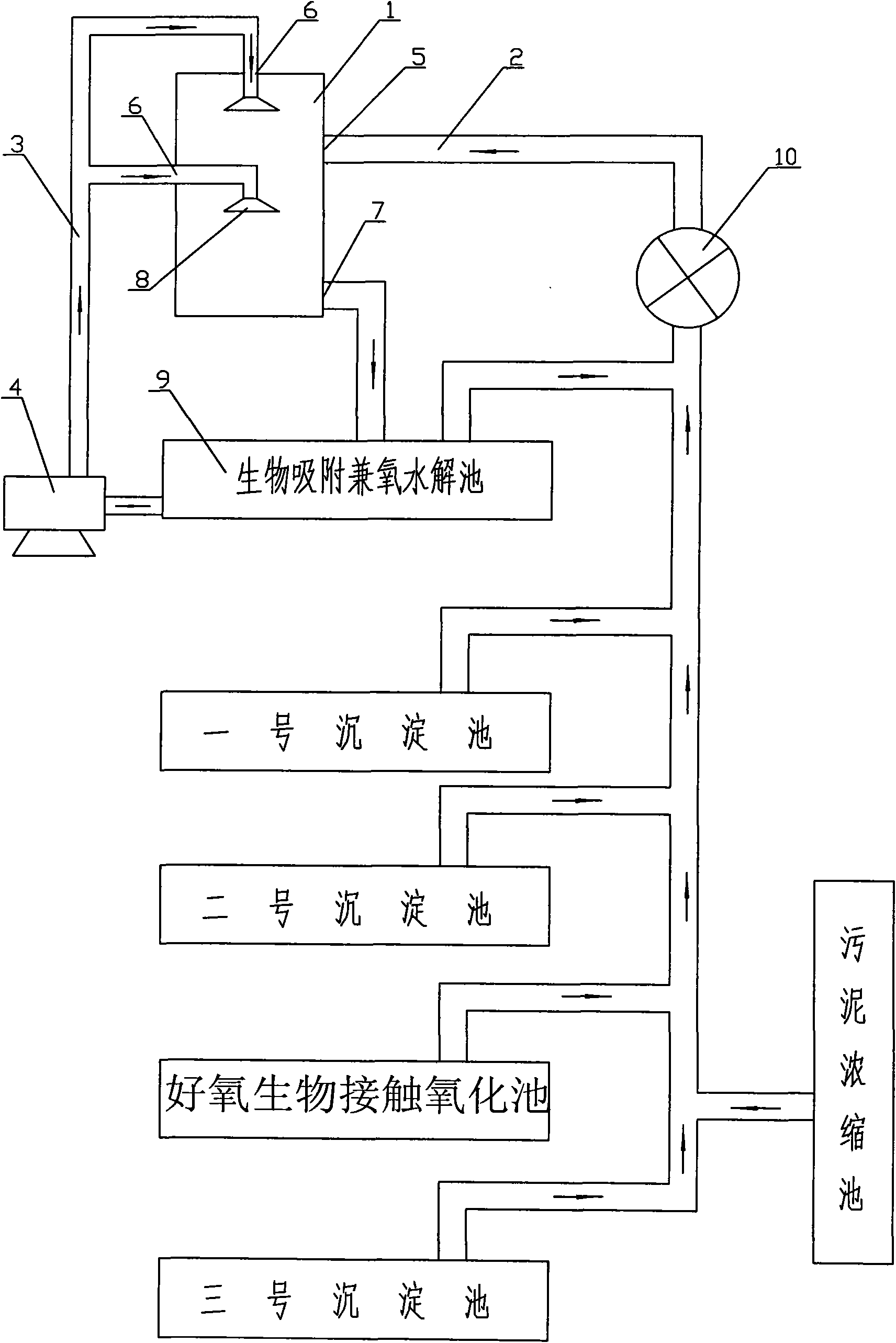

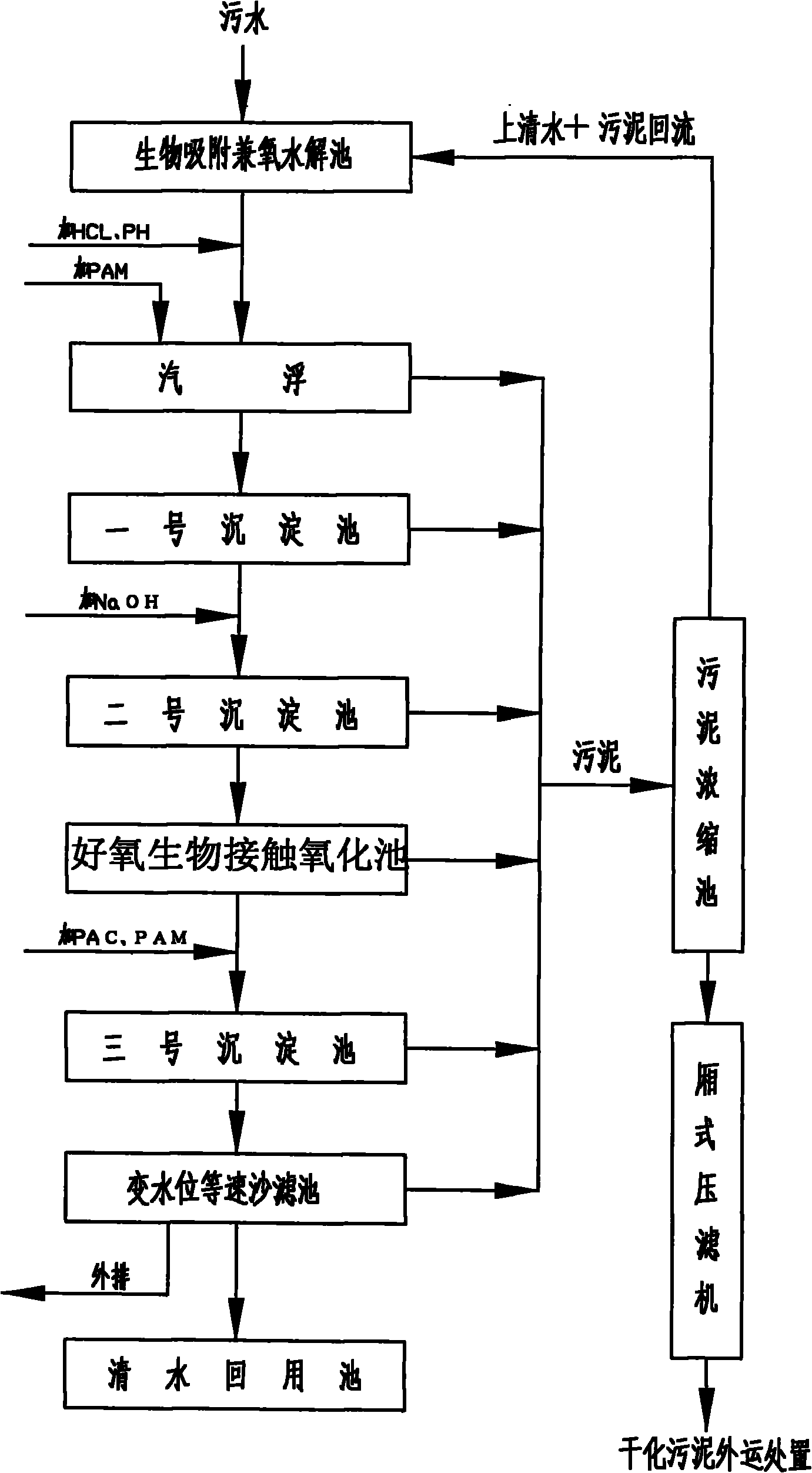

[0018] Depend on figure 1 and figure 2 As shown, a method for treating sewage in the refined cotton production process and controlling odor in pollution control, the process steps of the sewage treatment are as follows:

[0019] A. Biological adsorption and aerobic hydrolysis: adopt the method of sludge reflux to keep the concentration of activated sludge in the sewage at 4-5kg / m 3 The activated sludge biomass per cubic meter is 40-60kg, and the fan is used to aerate the oxygen to control the dissolved oxygen in the sewage at 0.3-0.6mg / L, so as to improve the biochemical effect of the sewage and reduce the Pollutant concentration;

[0020] B. Air flotation: After the sewage is bioadsorbed and aerobic hydrolyzed, it is pumped to the air flotation tank, and the HCL solution with a concentration of 10-15% is added to the sewage in the pipeline transported by the pump to keep the pH value of the sewage at 3-3.5. The gamma, beta cellulose and organic matter in the sewage are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com