System integrating sewage treatment with sludge concentration

A technology for sludge concentration and sewage treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Land occupation costs and other issues, to achieve the effect of reducing membrane investment and membrane operating costs, reducing sludge return ratio, and reducing contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

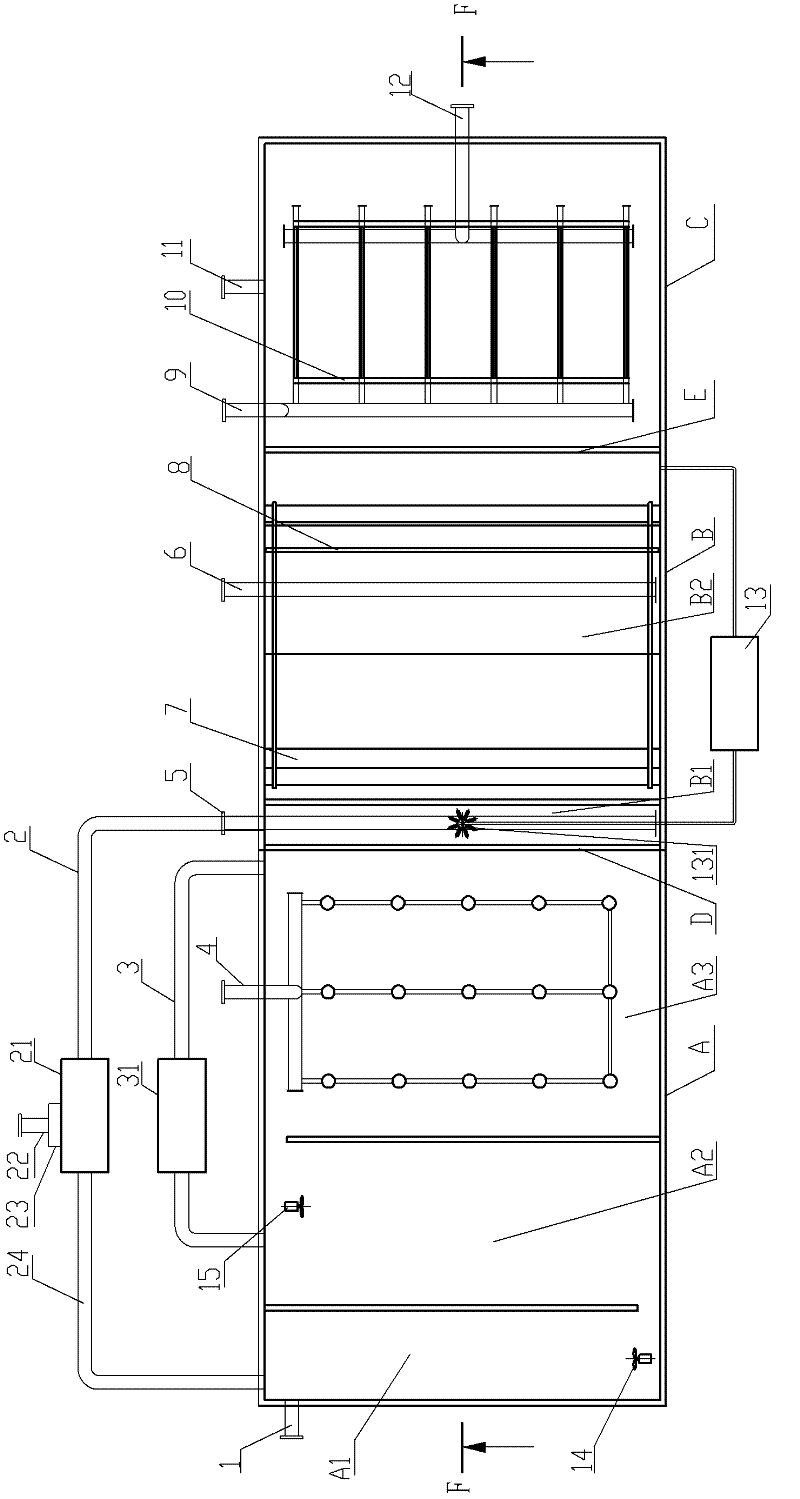

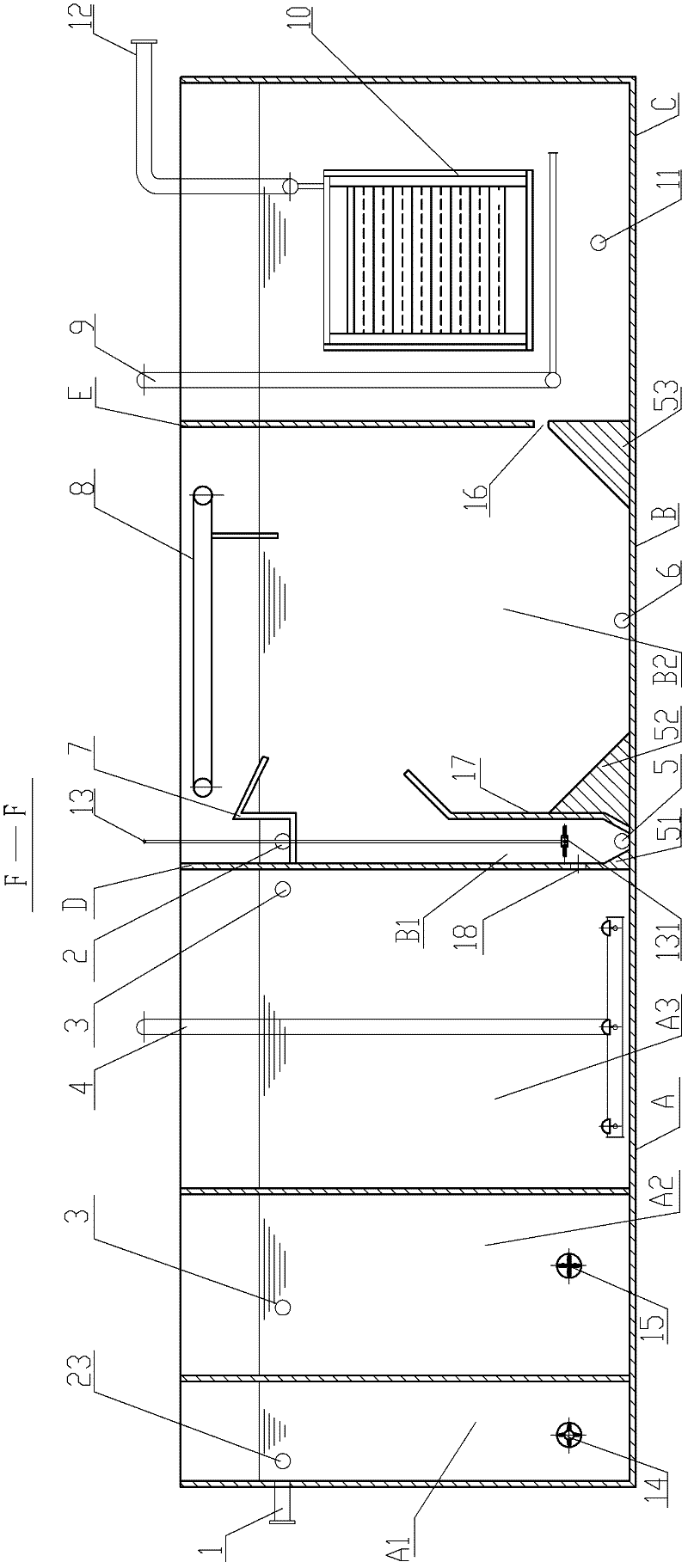

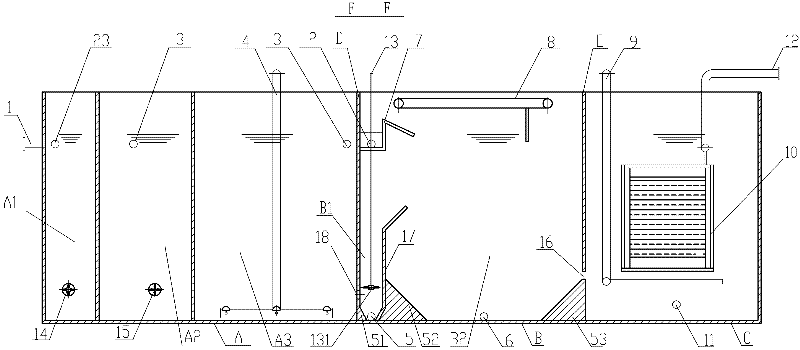

[0017] Figure 1 to Figure 2 An integrated system for sewage treatment and sludge concentration is shown, including a biological treatment tank A and a membrane separation tank C constituting a membrane biological treatment system. The biological treatment tank A is provided with an anaerobic zone A1, an anoxic zone A2, an inner The aerobic area A3 of the aerator 4 is set, and the water inlet pipe 1, the sludge return pipe 24 and the mixed liquid return pipe 3 are connected, and the two ends of the mixed liquid return pipe 3 are respectively connected with the aerobic area A3 and the anoxic area A2, Agitators 14 and 15 are respectively provided in the anaerobic zone A1 and the anoxic zone A2. The above-mentioned membrane separation tank C is provided with a membrane module 10, an aeration cleaner 9 and is provided with a water outlet pipe 12 and a membrane separation sludge discharge pipe 11. The air flotation tank B of the machine 13, and form the integral pool of the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com