Oxidation ditch membrane bioreactor, wastewater treatment process and application thereof

A membrane bioreactor, membrane bioreaction technology, applied in biological water/sewage treatment, biological treatment device, water/sludge/sewage treatment, etc. Low consumption, simple maintenance and operation, and the effect of reducing the cost of lifting pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

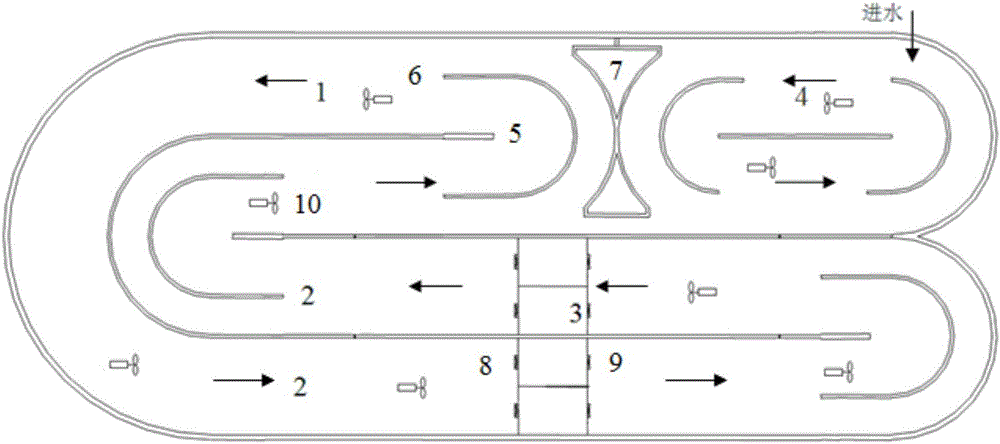

[0066] Oxidation ditch membrane bioreactor

[0067] like figure 1 As shown, the oxidation ditch membrane bioreactor is provided with an oxidation ditch, and the oxidation ditch membrane bioreactor includes anaerobic zone 4, anoxic zone 1 and aerobic zone 2 established continuously, and the aerobic zone 2 Four membrane bioreaction zones 3 are provided, and the sewage water inlet is set in the anaerobic zone 4 .

[0068] The oxidation ditch is in corridor type, and the oxidation ditch membrane bioreactor includes two oxidation ditches connected in series.

[0069] The oxidation ditch is formed by dividing the diversion wall, and includes a plurality of corridors.

[0070] The flow guide wall includes an intermediate partition wall 5 and / or an arc-shaped flow guide wall 6 .

[0071] The arc guide wall 6 is arranged at the free end of the middle partition wall 5 .

[0072] A partition wall 7 is set between the anaerobic zone 4 and the anoxic zone 1 .

[0073] The oxidation ...

Embodiment 2

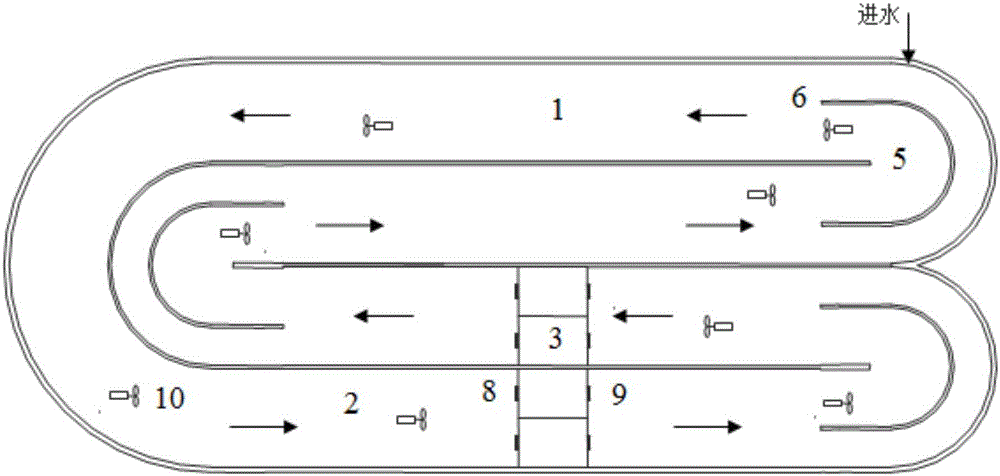

[0086] Oxidation ditch membrane bioreactor

[0087] like figure 2 As shown, the oxidation ditch membrane bioreactor is equipped with an oxidation ditch, and the oxidation ditch membrane bioreactor includes an anoxic zone 1 and an aerobic zone 2 set up continuously, and four membranes are arranged in the aerobic zone 2 In the biological reaction zone 3, the sewage water inlet is located in the anoxic zone 1.

[0088] The oxidation ditch is in corridor type, and the oxidation ditch membrane bioreactor includes two oxidation ditches connected in series.

[0089] The oxidation ditch is formed by dividing the diversion wall, and includes a plurality of corridors.

[0090] The flow guide wall includes an intermediate partition wall 5 and / or an arc-shaped flow guide wall 6 .

[0091] The arc guide wall 6 is arranged at the free end of the middle partition wall 5 .

[0092] The oxidation ditch membrane bioreactor is provided with two membrane bioreaction area groups, each membr...

Embodiment 3

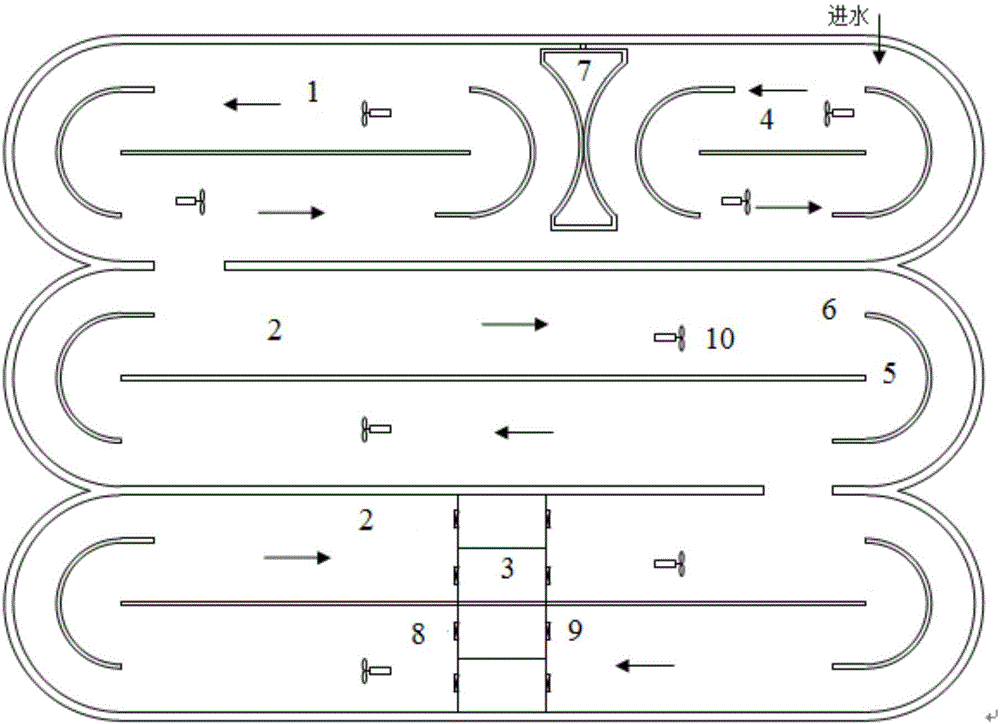

[0103] Oxidation ditch membrane bioreactor

[0104] like image 3 As shown, the oxidation ditch membrane bioreactor is provided with an oxidation ditch, and the oxidation ditch membrane bioreactor includes anaerobic zone 4, anoxic zone 1 and aerobic zone 2 established continuously, and the aerobic zone 2 Four membrane bioreaction zones 3 are provided, and the sewage water inlet is set in the anaerobic zone 4 .

[0105] The oxidation ditch is in corridor type, and the oxidation ditch membrane bioreactor includes three oxidation ditches connected in series.

[0106] The oxidation ditch is formed by dividing the diversion wall, and includes a plurality of corridors.

[0107] The flow guide wall includes an intermediate partition wall 5 and / or an arc-shaped flow guide wall 6 .

[0108] The arc guide wall 6 is arranged at the free end of the middle partition wall 5 .

[0109] A partition wall 7 is set between the anaerobic zone 4 and the anoxic zone 1 .

[0110] The oxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com