Method for removing micro-benzene in solvent oil or hexane refining process

A technology of solvent oil and hexane, which is applied in the field of extraction, rectification and separation of trace benzene, and removal of trace benzene, which can solve the problems of large loss of raw materials and increase of sulfur content in products, and achieve low investment, good effect and small reflux ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The raw material composition of solvent oil in a chemical plant is as follows

[0023] components

[0024] n-Hexane

[0025] It is required to cut out the food-grade distillate at 62-70°C, the benzene content is less than 50ppm, and the processing capacity of the raw material (stream 1) is 1000kg / h.

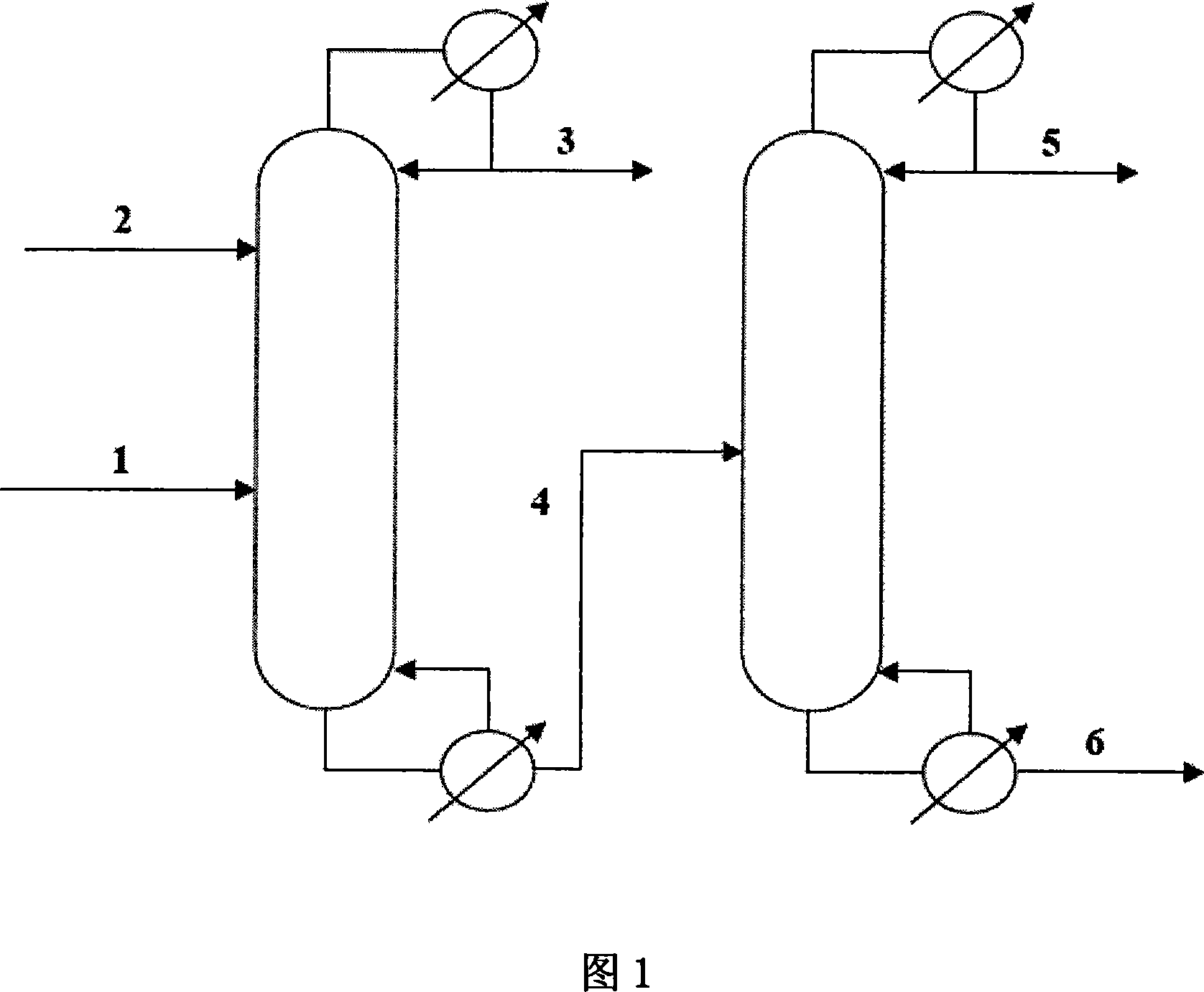

[0026] Furfural in the composite extractant (stream 2): ethylene glycol=0.3:0.7; the proportioning ratio of the raw material to the composite extractant is 1:1.2.

[0027] The top of the extraction and distillation tower is at normal pressure, the temperature at the top of the tower is 61.7-70°C, the temperature at the bottom of the tower is 135-140°C, the number of theoretical plates is 68, and the reflux ratio at the top of the tower is 3.5-4; CY700 wire mesh packing is used with a length of 16m, divided into 5 sections , and the top to bottom heights are 3 / 3.5 / 3.5 / 3 / 3m respectively, the position of the raw material entering the tower is above the fou...

Embodiment 2

[0033] The composition of industrial hexane in a factory is as follows

[0034] components

[0035] It is required to cut out 97.5% hexane product, benzene content <50ppm, and raw material (stream 1) processing capacity to be 500kg / h.

[0036] Furfural in the composite extractant (stream 2): ethylene glycol=0.8:0.2; the proportioning ratio of the raw material to the composite extractant is 1:0.6.

[0037] The top of the extractive distillation tower is at normal pressure, the temperature at the top of the tower is 68.7-70°C, the temperature at the bottom of the tower is 140-145°C, the number of theoretical plates is 78, and the reflux ratio at the top of the tower is 3.8; CY700 wire mesh packing is used for 18m, divided into 5 sections, and the top The downward heights are 4 / 3.5 / 3.5 / 3.5 / 3.5m respectively, the raw material enters the column above the packing of the fourth section (about 48 theoretical plates), and the compound extraction agent enters the column above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com