Cracking gas separation method and cracking gas separation apparatus

A separation method and technology of a separation device, which are applied in the directions of absorption purification/separation, distillation purification/separation, gas fuel, etc., can solve the problems of insufficient utilization of carbon two carbon three resources, low investment recovery rate and high energy consumption, and achieve The effect of relaxing methane content, reducing investment and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

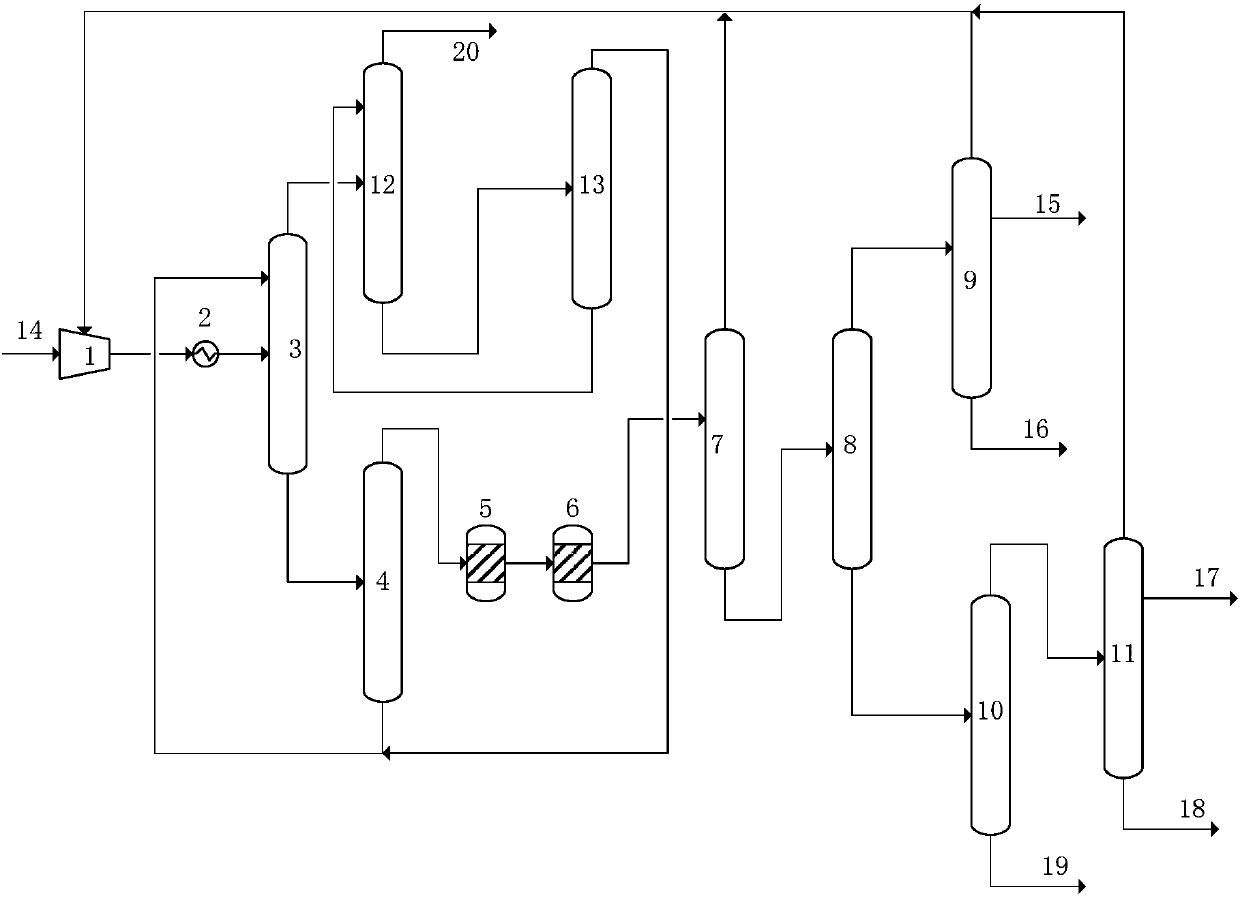

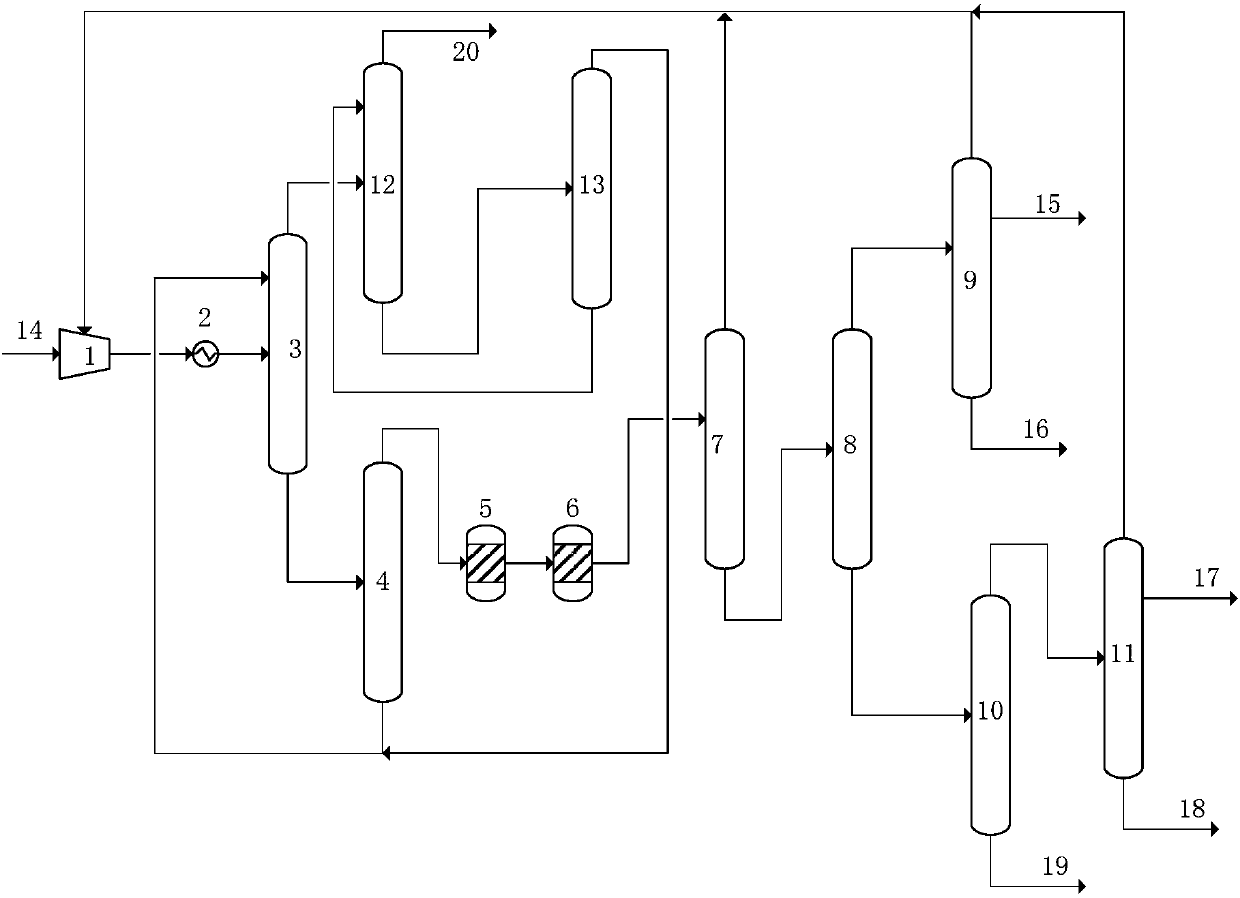

[0063] use as figure 1 The cracked gas separation device shown. The cracked gas separation device comprises a compressor 1, a cooler 2, an absorption tower 3, a desorption tower 4, a purification unit 5, a drying unit 6, a demethanizer 7, a deethanizer 8 and an ethylene rectification tower 9 connected in sequence; The top of the absorption tower 3 is connected to the reabsorption tower 12 and the gasoline stabilization tower 13, and the bottom of the tower is connected to the desorption tower 4; the top of the desorption tower 4 is connected to the purification unit 5 and the drying unit 6 in turn, and then connected to the demethanizer 7; The bottom of the demethanizer 7 is connected to the deethanizer 8; the top of the deethanizer 8 is connected to the ethylene rectification tower 9, and the bottom of the tower is connected to the depropanizer 10; The kettle is connected to the production line of ethane-rich products; the top of the depropanizer 10 is connected to the propy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com