Double-reflux denitrification membrane-bioreactor (MBR) process for treating dry acrylic fiber waste water

A dry-process acrylic fiber and double-reflux technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of incomplete nitrification and denitrification process and increase engineering sewage treatment facilities Infrastructure costs and operating costs, the total nitrogen content of the effluent cannot meet the standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

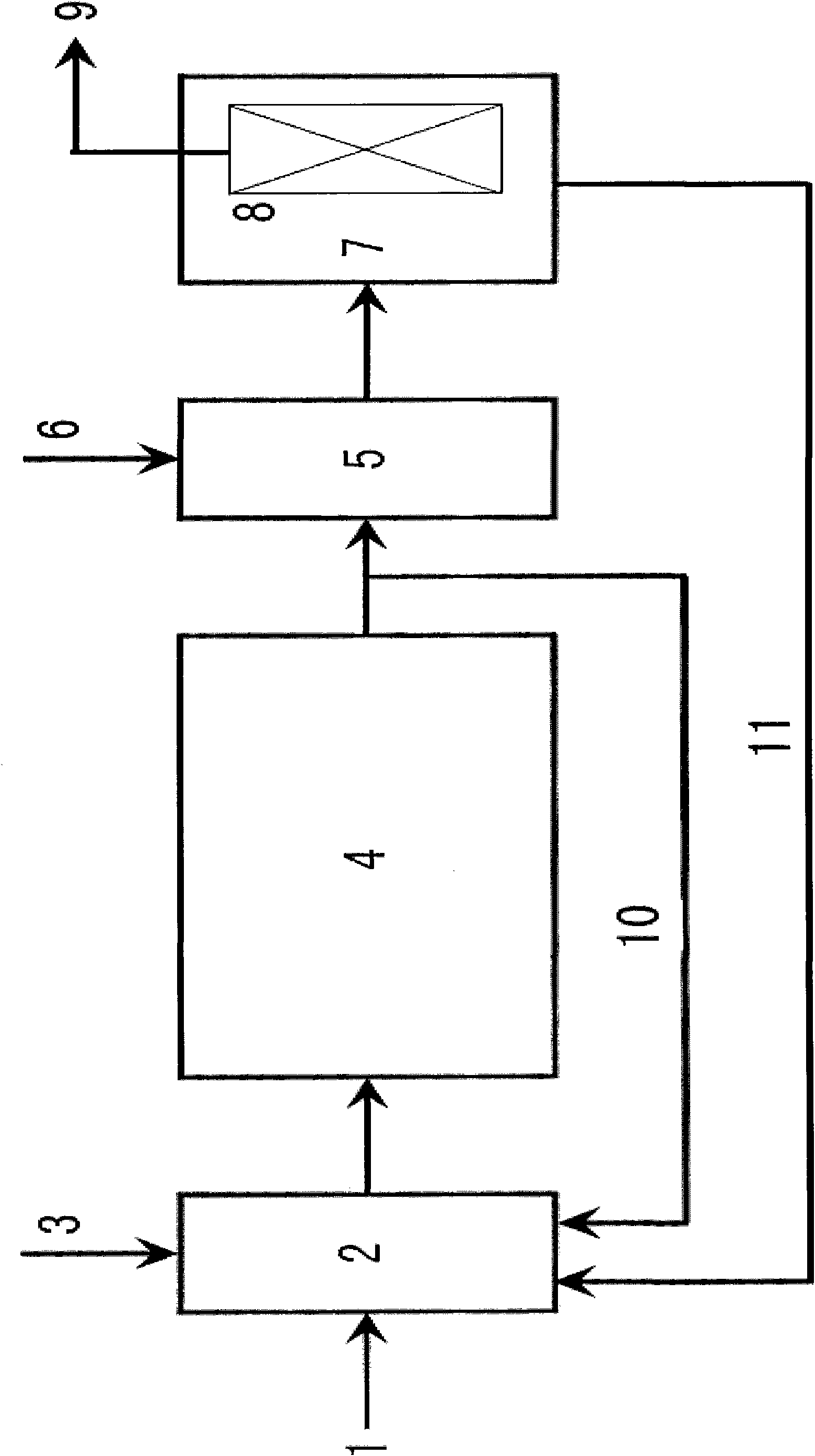

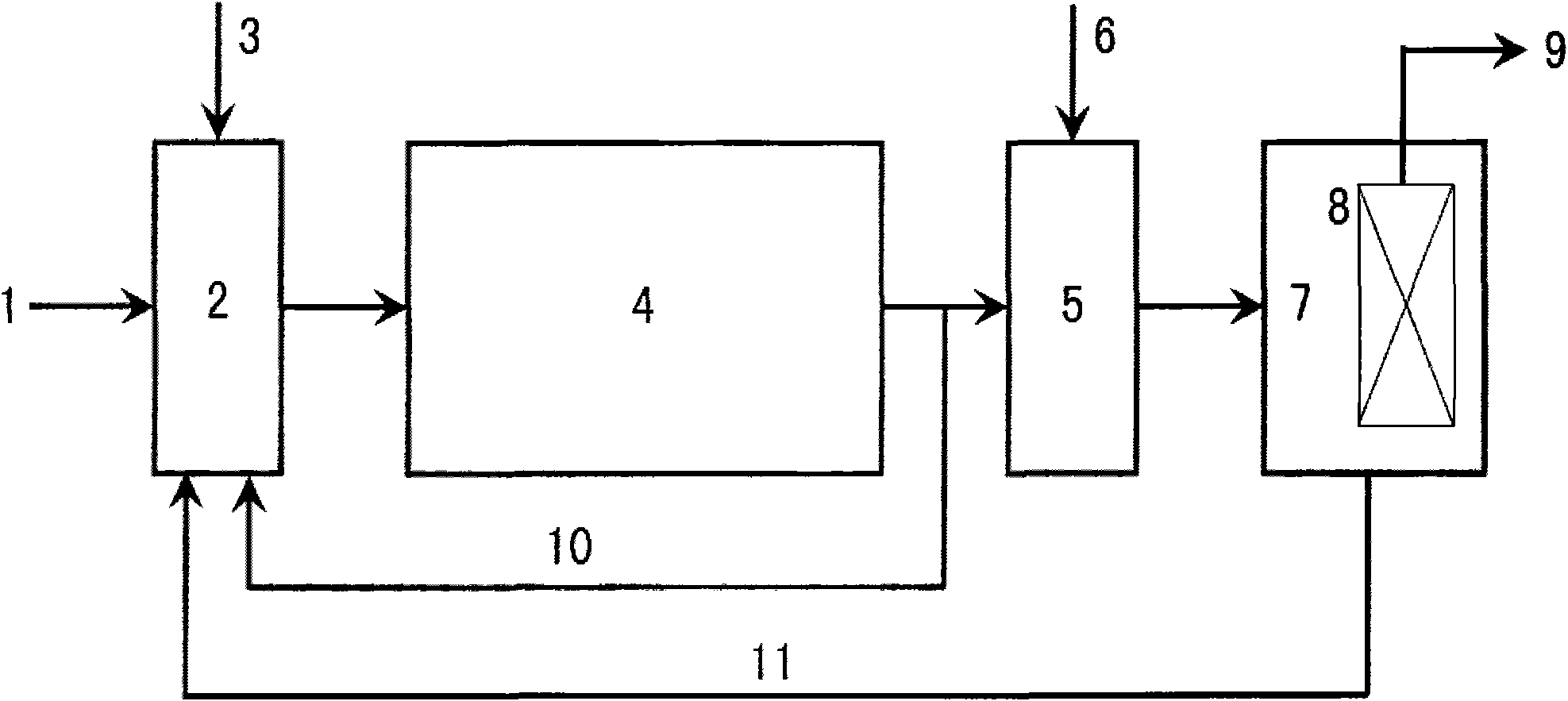

[0020] Using the above embodiment as a biochemical treatment unit to treat the effluent from the anaerobic pond of a dry-process acrylic fiber factory in Northeast China, the full analysis shows that the refractory nitriles, nitrogen-containing heterocycles, alkanes and amino organic compounds in the effluent account for more than 86%. , influent COD Cr 950~1200mg / L, BOD 5 150~300mg / L, NH 4 + -N is about 80mg / L, TN is about 160mg / L, B / C is 0.15~0.25, which is difficult for biodegradable wastewater. The size of the reactor is: L 48cm×B 37cm×H 65cm, V 前置缺氧池 :V 好氧池 :V 后置缺氧池 :V 膜分离池 =1:4:1:1.5, the total effective volume is 99L, the reflux ratio of the nitrifying liquid in the aerobic tank is 150%, the reflux ratio of the sludge concentrate in the membrane separation tank is 70-100%, and the total residence time is 30h. Effluent COD 190~360mg / L, NH 4 + -N<5mg / L, TN 30~40mg / L, the average COD removal rate is 70~80% COD, the ammonia nitrogen removal rate is over 97%, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com