Industry formaldehyde waste water treatment and recycling recovery process thereof

A formaldehyde waste water recycling technology, applied in the chemical industry, heating water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve good separation effect, large processing capacity, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

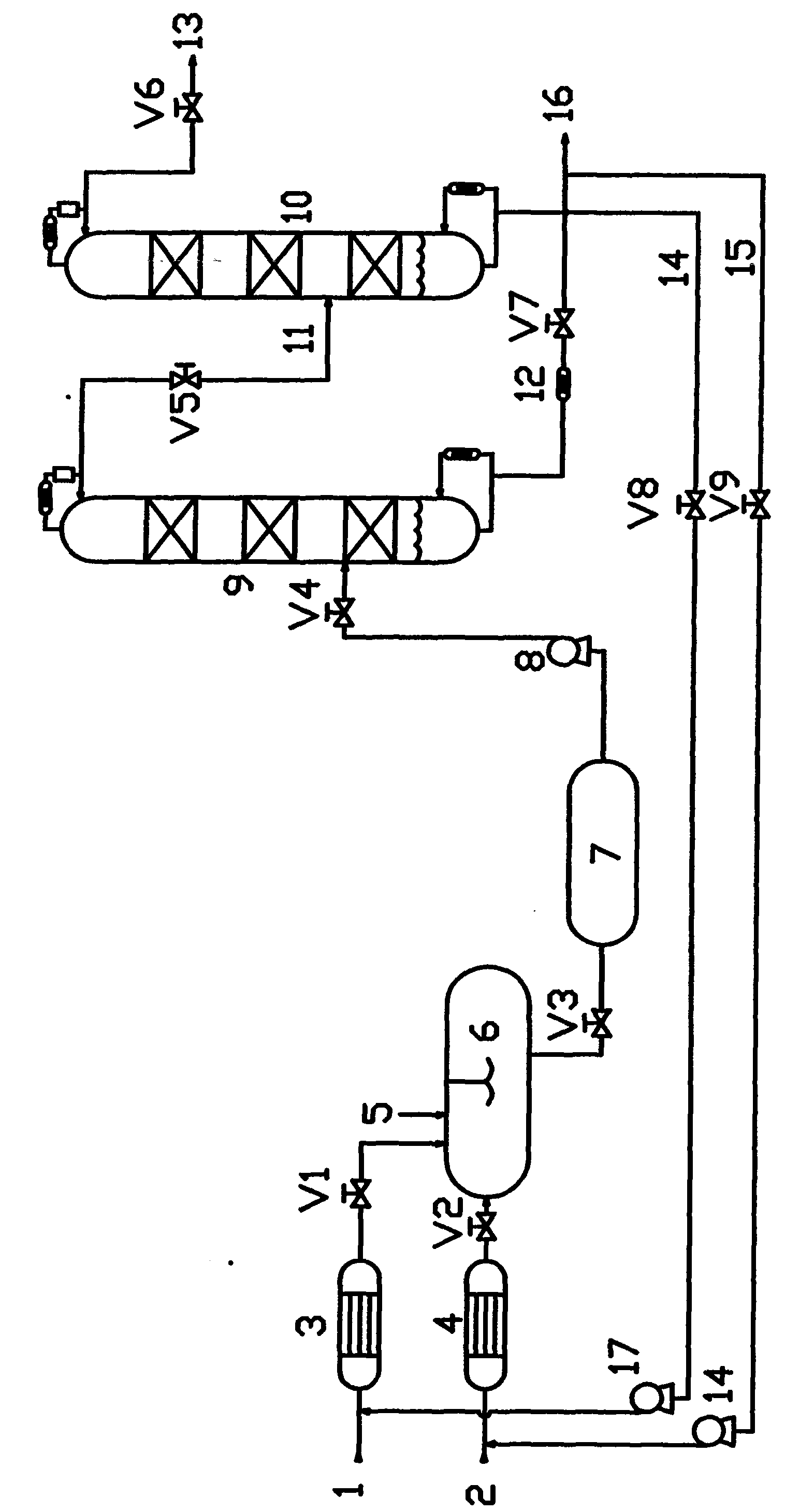

Image

Examples

Embodiment 1

[0032] Example 1: Treatment of 1% formaldehyde wastewater and resource utilization of formaldehyde

[0033] The composition of formaldehyde wastewater is 1% formaldehyde mass concentration, and the rest is water. The wastewater stream feeds 8000Kg at one time, and the temperature reaches 70-75°C after heat exchange. According to the ratio of the amount of alcohol and aldehyde substances to 20, 1700Kg of 95% industrial methanol is fed at one time, and the temperature of methanol reaches 60-65°C after heat exchange. ℃, while adding 320Kg of strongly acidic cation exchange resin (provided by Jiangsu Yonghua Fine Chemicals Co., Ltd., the same below) with 4% of the quality of waste water to be treated as a catalyst, controlling the temperature of the reactor to 70-80 ℃, and the situation of stirring speed 200r / min The reaction was carried out for 30 minutes. After the reaction was completed, the valve V3 was opened, and the waste water system entered the storage tank 7.

[0034]Th...

Embodiment 2

[0036] Example 2: Treatment of 5% formaldehyde wastewater and resource utilization of formaldehyde

[0037] The composition of formaldehyde wastewater is 5% formaldehyde mass concentration, and the rest is water. The wastewater stream is fed 6000Kg at one time, and the temperature reaches 70-75°C after heat exchange. According to the aldol ratio of 10, 3200Kg of 95% industrial methanol is fed at one time, and the temperature of methanol reaches 60-65°C after heat exchange. Treat 120Kg of strongly acidic cation exchange resin with 2% of the mass of wastewater as a catalyst, control the temperature of the reactor at 65-75°C, and react for 30 minutes at a stirring speed of 200r / min. After the reaction is completed, open the valve V3, and the wastewater system enters the storage tank.

[0038] With the operation of the primary rectification tower of embodiment 1, the formaldehyde concentration monitoring in the tower still of the primary rectification tower is 0.2%, and the up-to-...

Embodiment 3

[0039] Example 3: Treatment of 5% formaldehyde wastewater and formaldehyde resource utilization (2)

[0040] On the basis of Example 2, feed 1600Kg of 95% industrial methanol at one time according to the aldol ratio of 5, and adjust the temperature of the reactor at 70-80°C and other reaction conditions remain unchanged, and operate with the first-stage rectifying tower of Example 2 , the concentration of formaldehyde in the waste water in the bottom of the primary distillation tower is monitored as 0.5%, which fails to reach the standard. The measures taken are to enter the feed port of the formaldehyde waste water through the valve V9 and the pump, and the waste water outflow of the bottom of the tower is 7720Kg / h. The outflow of methanol and methylal mixed liquid at the top of the primary rectification tower is 2280Kg / h; % of methylal, its output is 910Kg / h, and the secondary rectification tower bottom obtains 1370Kg / h methanol through valve V8 and pump reflux circulation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com