Device and method for preparing high-purity nitrogen monoxide from adipic acid production tail gases

A technology for nitrous oxide and adipic acid, which is applied in the fields of nitrous oxide, nitrogen oxides/oxyacids, chemical industry, etc., and can solve problems such as low tower top temperature, increased energy consumption of refrigerators, and high production costs , to achieve the effect of reducing the return flow and reducing the energy consumption of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

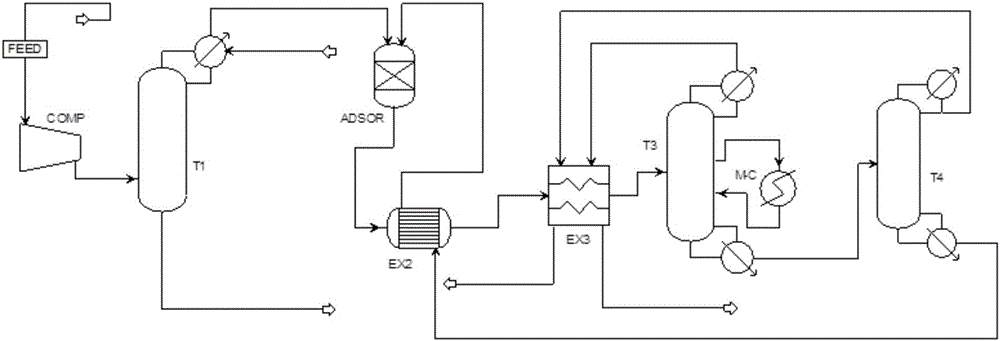

[0031] A device for preparing high-purity nitrous oxide from tail gas produced by adipic acid, its structure is as follows figure 1 As shown, high-purity nitrous oxide is prepared by using the tail gas of the adipic acid production plant (see Table 1 for the composition, the processing capacity is 61.5 kmol / h, and the mass flow rate is 2.25 t / h). The process equipment involved includes compressor COMP, absorption tower T1 , heat exchanger, adsorption device ADSOR, cryogenic distillation tower T3, cryogenic refining tower T4 and connecting pipelines. Among them, the absorption tower T1, the cryogenic rectification tower T3, and the cryogenic rectification tower T4 all have tower top condensers, and the cryogenic rectification tower T3 and the cryogenic rectification tower T4 all have tower bottom reboilers. The cryogenic rectification tower T3 has a total of 20 theoretical towers plate, on the fifth theoretical plate there is an intermediate condenser M-C.

[0032] Table 1. Ta...

Embodiment 2

[0042] Other conditions are the same as in Example 1, N in the exhaust gas 2 The mass concentration of O is less than 0.01%, and the low-temperature rectification tower T3 does not have an intermediate condenser. At this time, the temperature at the top of the cryogenic rectification tower T3 is -149.1°C, and the cooling power of the top condenser is 255kw. Based on the ambient temperature of 25°C, the theoretical power consumption required for refrigeration of the cryogenic rectification tower T3 is 358kw.

Embodiment 3

[0044] A device for preparing high-purity nitrous oxide from tail gas produced by adipic acid, including a compressor, an absorption tower, an adsorption device, a low-temperature rectification tower, and a low-temperature refining tower connected in sequence. The gas from the adsorption device is cooled by a heat exchanger and then enters Low-temperature rectification tower, the exhaust gas at the top of the low-temperature rectification tower recovers the cold energy and sends it to the tail gas treatment system, the liquid stream at the bottom of the tower enters the low-temperature refining tower, and high-purity N 2 O, fill after recovering the cooling capacity.

[0045] Among them, the trays provided in the cryogenic rectification tower are adjusted with the increase or decrease of the reflux ratio. In this embodiment, there are 10 trays in total. An intermediate condenser is arranged at the middle and upper positions of the cryogenic rectification tower, and the absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com