Method for removing impurities contained in high-impurity crude silver

A crude silver and impurity technology, which is applied in the field of removing impurities in high-impurity crude silver, can solve the problems that are not suitable for special industrial purposes and affect the mechanical, physical and chemical properties of metals, so as to maximize product benefits and ensure purity and fineness , The effect of reducing unit power consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Crude silver melting: take crude silver as raw material, the impurity content is: Cu 0.20%, Bi 0.004%, Fe 0.004%, Pb 0.02%, Sb 0.0029%, Pd 0.003%, Se 0.009%, Te 0.008%, the crude silver Put it into a graphite clay crucible and melt it completely in an intermediate frequency furnace at 1190 ° C. In the molten state, the flowing melt is reddish white and kept for 10 minutes;

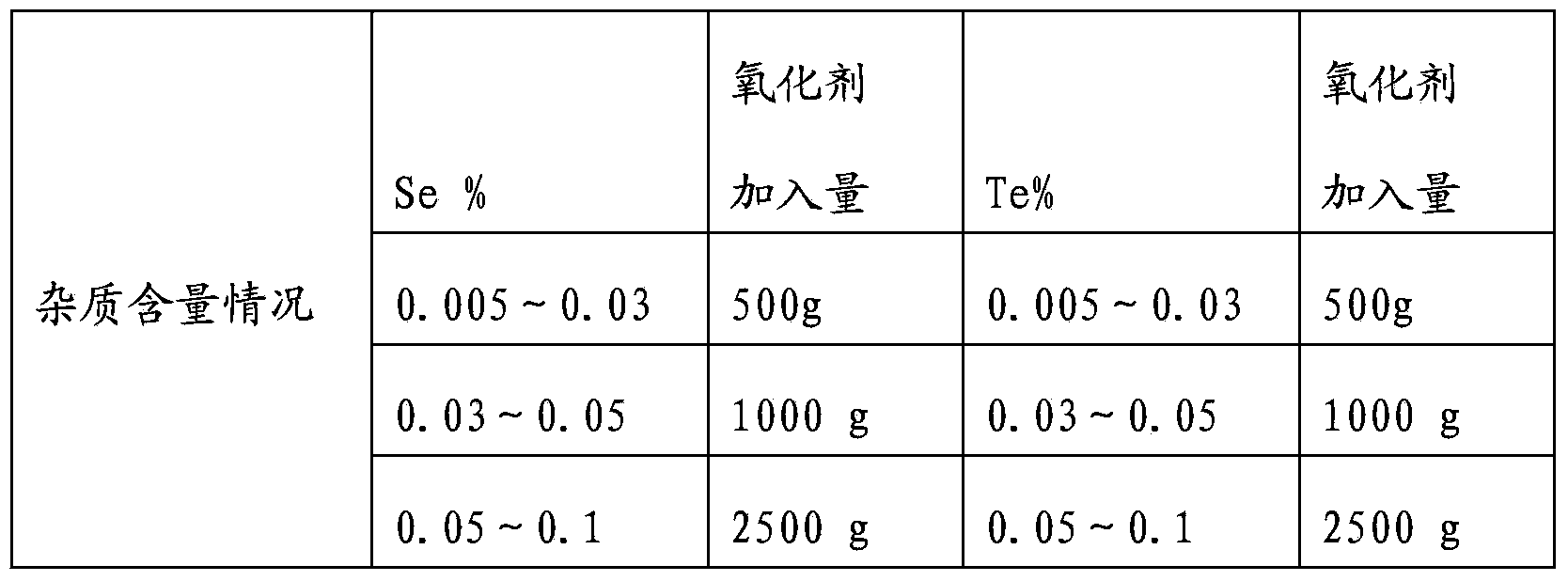

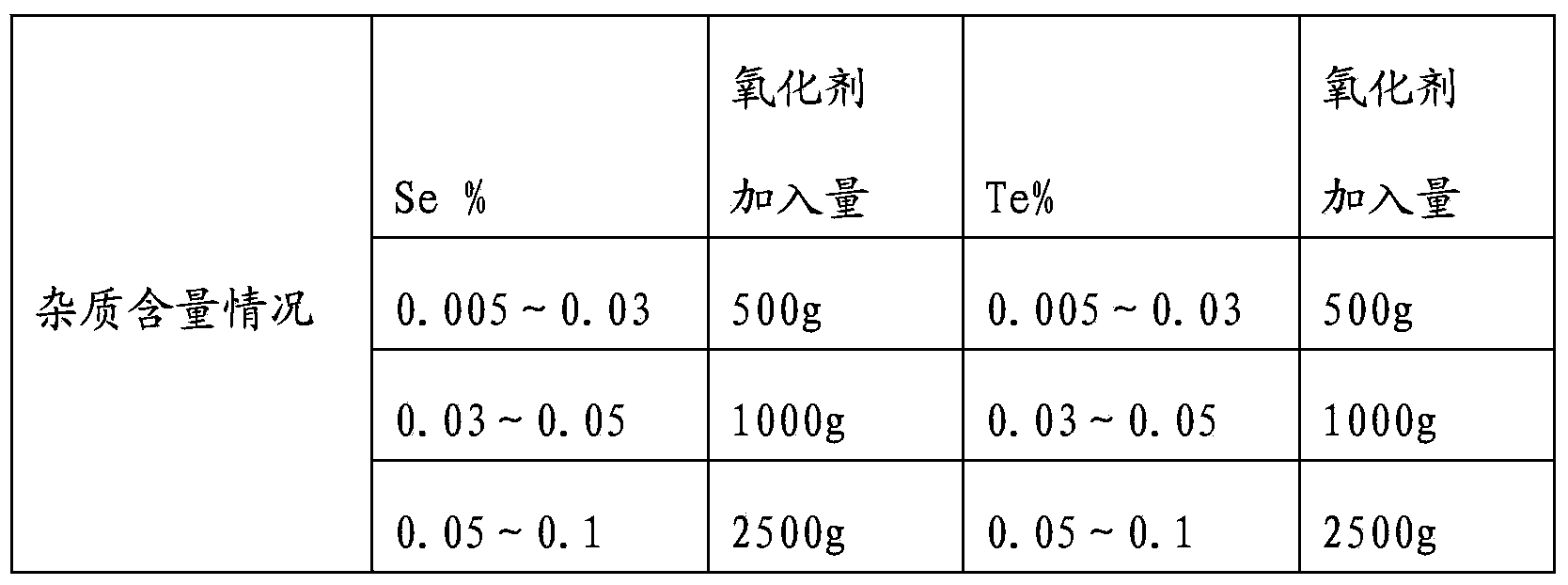

[0026] 2) Adding an oxidizing agent: After the melt reaches the above state, according to the content of the impurities Se and Te in the crude silver, the oxidizing agent consisting of potassium nitrate, borax and sodium peroxodisulfate in a mass ratio of 1:0.8:0.6 is added to the melt at one time. In the liquid, the addition amount of the oxidizing agent is 1000g, observe the color of the molten liquid at this moment, turn from red white to dark red-then turn to light red-and then gradually turn red white, this process controls the reaction time according to the amount of adding oxidant as After...

Embodiment 2

[0036]1) Crude silver melting: take crude silver as raw material, the impurity content is: Cu 0.018%, Bi 0.006%, Fe 0.006%, Pb 0.03%, Sb 0.003%, Pd 0.004%, Se 0.03%, Te 0.04%, the crude silver Put it into a graphite clay crucible and melt it completely in an intermediate frequency furnace at 1200 ° C. In the molten state, the flowing melt is reddish white and kept for 12 minutes;

[0037] 2) Adding an oxidizing agent: After the melt reaches the above state, according to the content of impurities Se and Te in the crude silver, the oxidizing agent composed of potassium nitrate, borax and sodium peroxodisulfate in a mass ratio of 1:0.9:0.7 is added to the melt at one time. In the liquid, the addition amount of oxidizing agent is 2000g, observe the color of molten liquid at this moment, turn from red-white to dark red-then turn into light red-return to red-white gradually, this process controls the reaction time according to the amount of adding oxidant as After 15 minutes, the Se...

Embodiment 3

[0047] 1) Crude silver melting: Take crude silver as raw material, the impurity content is: Cu: 0.023%, Bi: 0.008%, Fe: 0.008%, Pb: 0.04%, Sb: 0.004%, Pd: 0.005%, Se: 0.02%, Te: 0.03%, put crude silver into a graphite clay crucible, and melt it completely in an intermediate frequency furnace at 1250 ° C. In the molten state, the flowing melt is reddish white, and keep it for 15 minutes;

[0048] 2) Adding an oxidizing agent: After the melt reaches the above state, according to the content of impurities Se and Te in the crude silver, the oxidizing agent composed of potassium nitrate, borax and sodium peroxodisulfate in a mass ratio of 1:1.0:0.8 is added to the melt at one time. In the liquid, the addition amount of oxidizing agent is 1000g, observe the color of molten liquid at this moment, turn from red white to dark red-then turn to light red-return to red white gradually again, this process controls the reaction time according to the amount of adding oxidant as In 20 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com