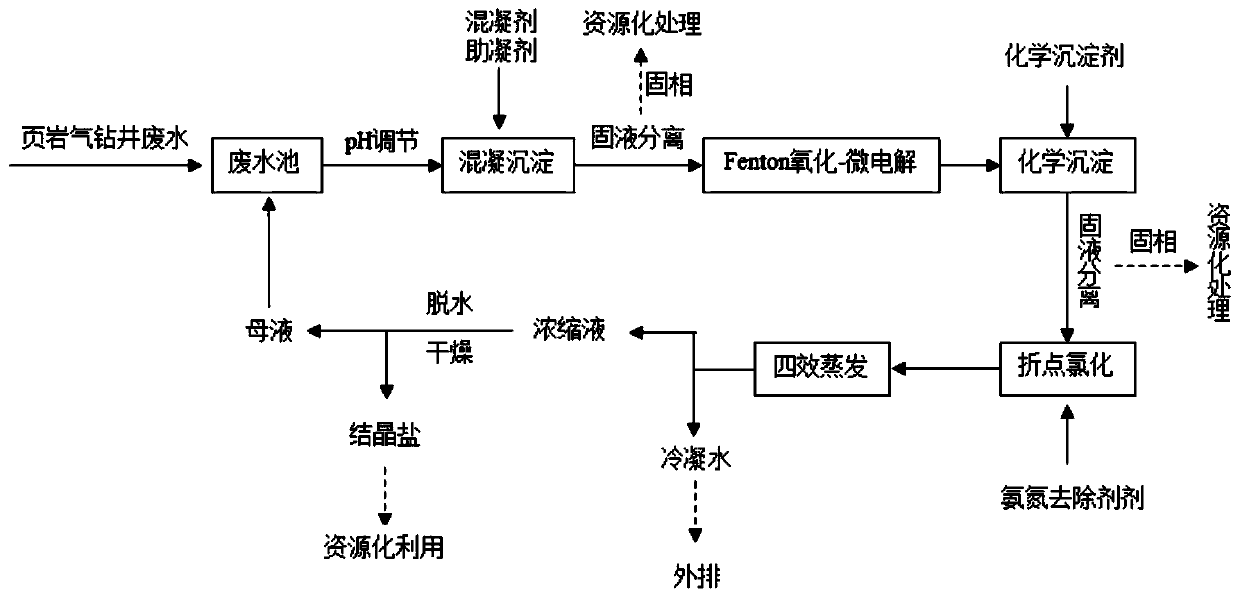

Shale gas drilling wastewater treatment method

A technology of drilling wastewater and treatment method, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. High volume, complex chemical composition and other problems, to achieve the effect of convenient boiler maintenance, reduction of ammonia nitrogen content, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

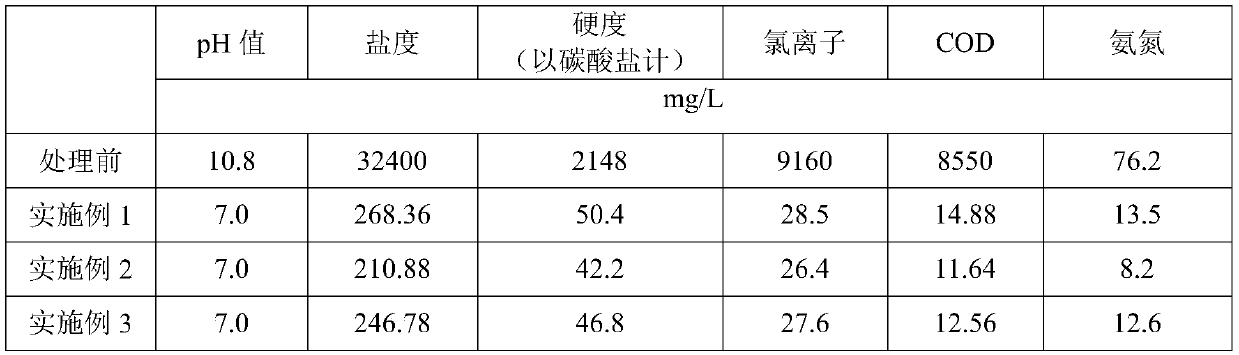

Embodiment 1

[0038] Embodiment 1, a kind of shale gas drilling wastewater treatment method comprises the following steps:

[0039] Step 1: Introduce the drilling wastewater in the wastewater tank into the coagulation sedimentation tank through the pipeline, adjust the pH value of the drilling wastewater in the coagulation sedimentation tank to 8, add coagulant and coagulant aid, and the amount of coagulant added is 0.8kg / m 3 , the amount of coagulant aid added is 0.025kg / m 3 , stirred at a slow speed and then left to settle, and then solid-liquid separation was carried out to obtain the primary wastewater for the first removal of COD and SS. Recycling of materials;

[0040] Step 2: Adjust the pH value of the primary wastewater in the Fenton oxidation-micro-electrolytic cell to 2, add hydrogen peroxide and Fe / C filler, and add 30% hydrogen peroxide to 4L / m 3 , the amount of Fe / C filler added is 300kg / m 3 , and pump air in, the air-water ratio is controlled to be 8:1, and after 2 hours of...

Embodiment 2

[0044] Embodiment 2, a kind of shale gas drilling wastewater treatment method, comprises the following steps:

[0045] Step 1: Introduce the drilling wastewater in the waste water pool into the coagulation sedimentation tank through the pipeline, and add coagulant and coagulant aid to the drilling wastewater 9 in the coagulation sedimentation tank, and the amount of coagulant added is 1kg / m 3 , the amount of coagulant aid added is 0.05kg / m 3 , stirred at a slow speed and then left to settle, and then solid-liquid separation was carried out to obtain the primary wastewater for the first removal of COD and SS. Recycling of materials;

[0046] Step 2: Adjust the pH value of the primary wastewater in the Fenton oxidation-micro-electrolytic cell to 3, add hydrogen peroxide and Fe / C filler, and add 30% hydrogen peroxide to 6L / m 3 , the amount of Fe / C filler added is 500kg / m 3 , and pump in the air, the air-water ratio is controlled at 5:1, and after 2 hours of reaction, the secon...

Embodiment 3

[0050] Embodiment 3, a kind of shale gas drilling wastewater treatment method, comprises the following steps:

[0051] Step 1: Introduce the drilling wastewater in the wastewater tank into the coagulation sedimentation tank through the pipeline, adjust the pH value of the drilling wastewater in the coagulation sedimentation tank to 11, add coagulant and coagulant aid, and the amount of coagulant added is 1.2kg / m 3 , the amount of coagulant aid added is 0.075kg / m 3 , stirred at a slow speed and then left to settle, and then solid-liquid separation was carried out to obtain the primary wastewater for the first removal of COD and SS. Recycling of materials;

[0052] Step 2: Adjust the pH value of the primary wastewater in the Fenton oxidation-micro-electrolytic cell to 5, add hydrogen peroxide and Fe / C filler, and add 30% hydrogen peroxide to 8L / m 3 , the amount of Fe / C filler added is 500kg / m 3 , and pump air in, the air-water ratio is controlled at 10:1, and after 2 hours of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com