Accurate feeding method and device in sewage treatment processes

A technology of precise feeding and sewage treatment, applied in flocculation/sedimentation water/sewage treatment, energy wastewater treatment, non-electric variable control, etc., can solve problems such as small flocs, difficult to handle, and increased moisture content of sludge, and achieve Save casting, save cost, and ensure the effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

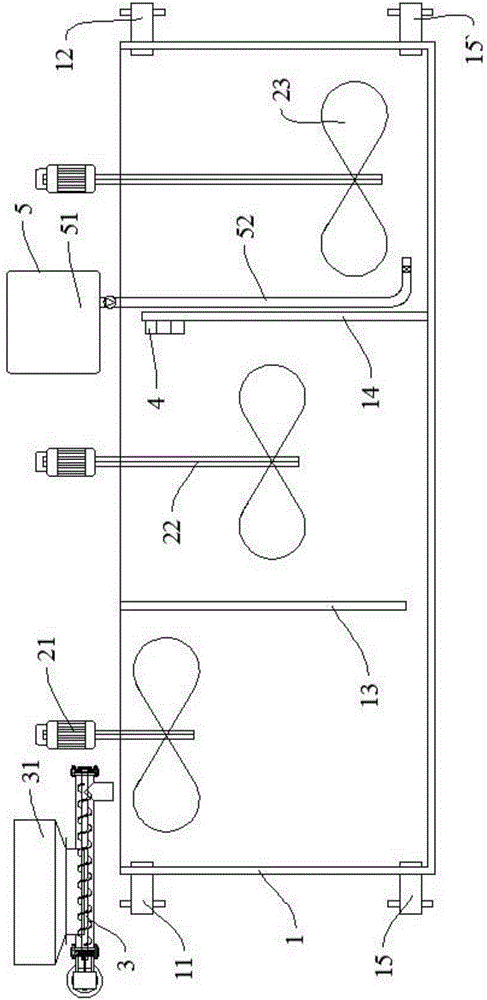

[0031] like figure 1 As shown, a precise feeding device in the sewage treatment process, including: reaction tank 1, propeller, dosing machine 3, liquid level gauge 4, dosing machine 5, flow valve, flow meter, temperature sensor, PH value sensor, DO Sensors, suspended solid sensors, conductivity sensors, computer control systems;

[0032] The water inlet pipe 11 of the reaction tank 1 is arranged on the upper part of the water inlet side of the reaction tank, the outlet pipe 12 of the reaction tank 1 is arranged on the upper part of the water outlet side of the reaction tank 1, and the first baffle 13 and the second baffle are arranged in the reaction tank 1. The baffle 14, the first baffle 13 and the second baffle 14 divide the body of the reaction tank 1 into three sections from the water inlet side to the water outlet side, and the upper edge of the first baffle 13 is flush with the top of the pool body There is a gap of 150-250 mm between the lower edge of the first baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com