Production line for production of LED lamps

A technology of LED lamps and production lines, applied in sorting and other directions, can solve problems such as omissions, defective products mixed in, affecting the quality of finished lamps, etc., and achieve the effect of ensuring the removal rate of defective products and the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

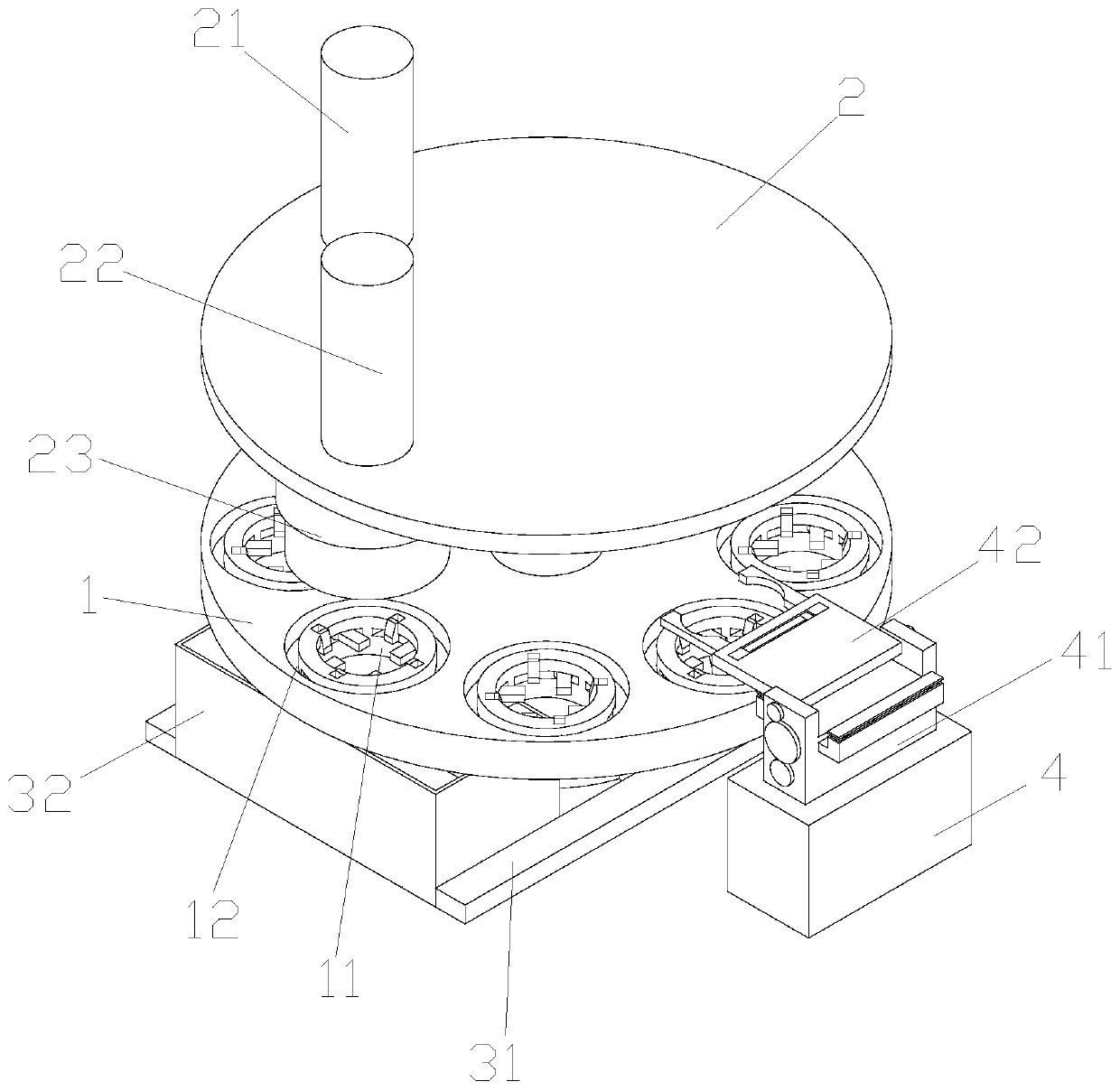

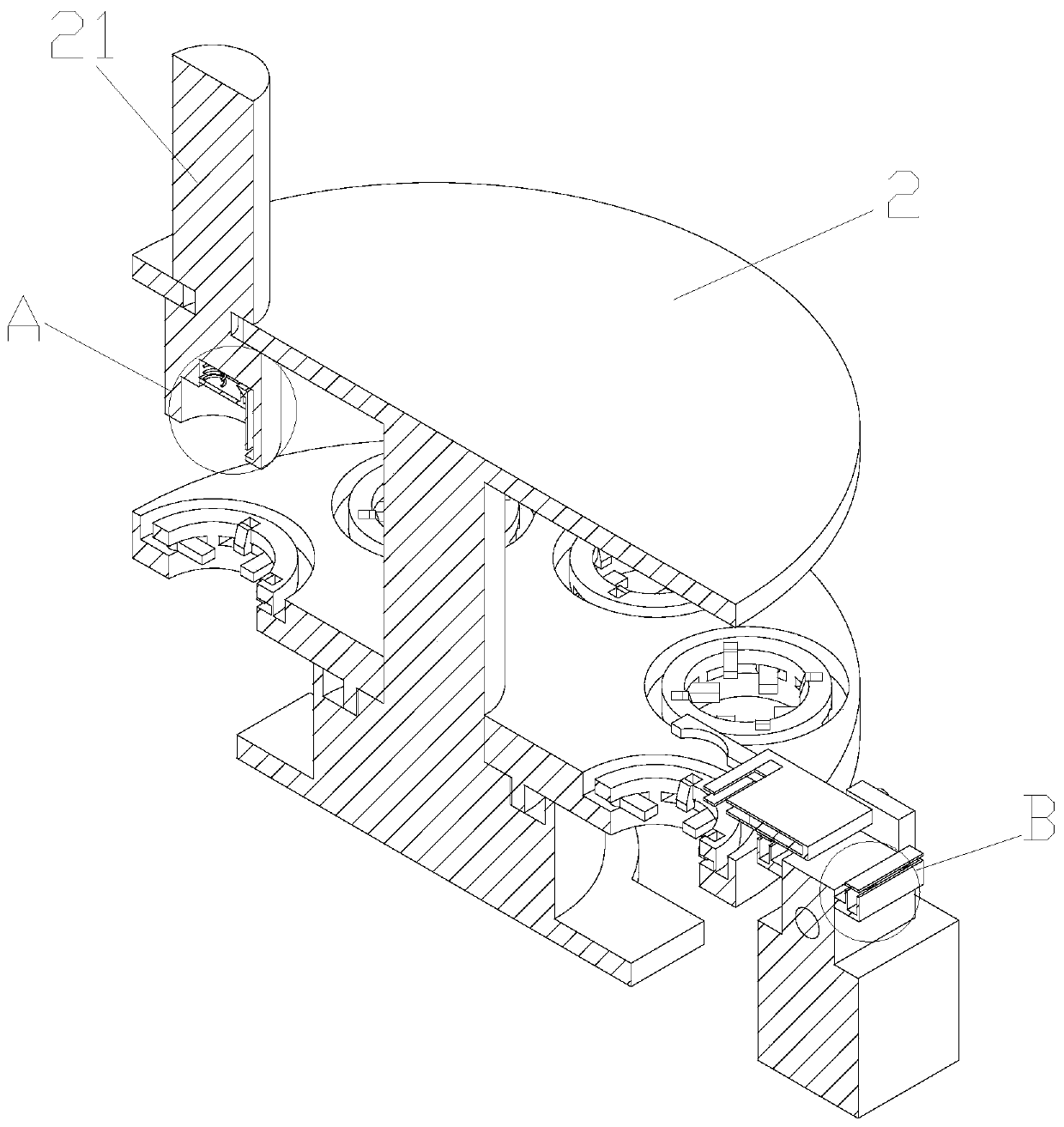

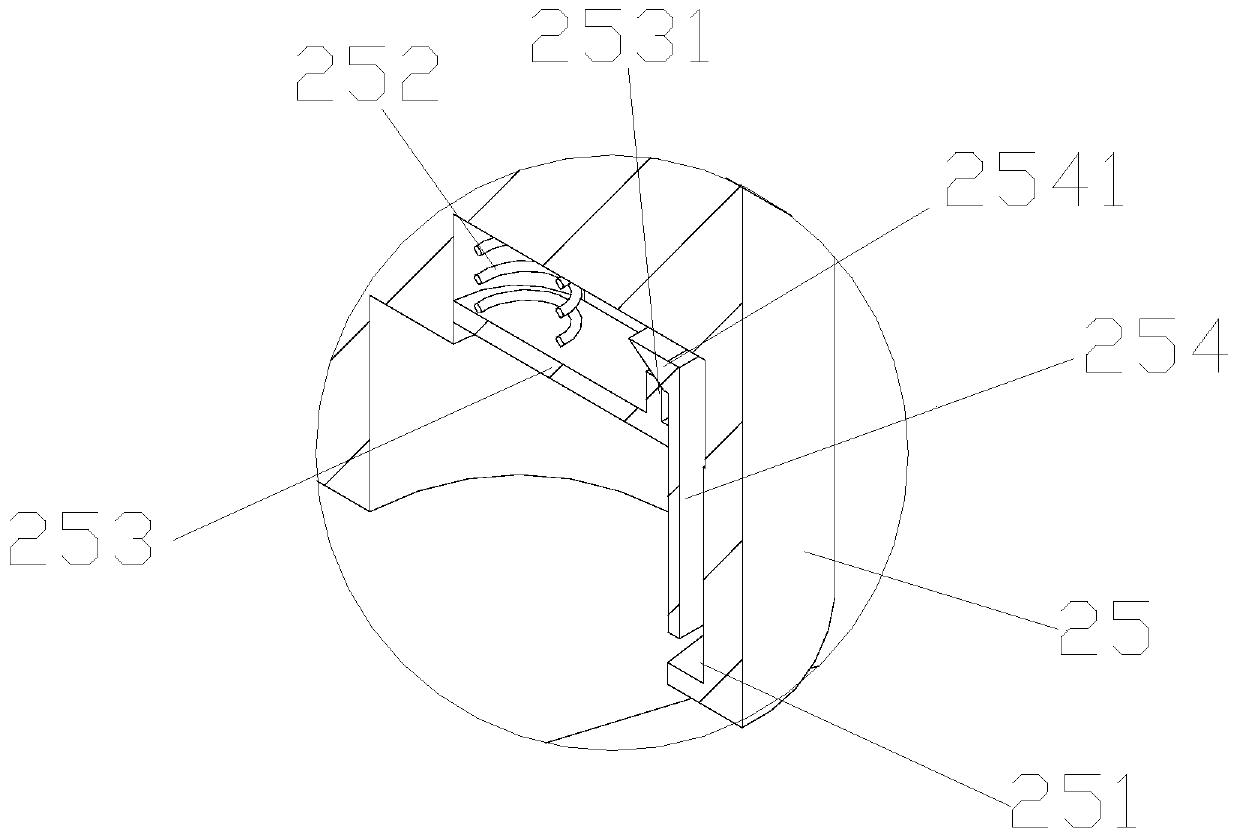

[0024] like Figure 1-10 As shown, a production line based on the production of LED lamps includes a turntable 1, a base 3 arranged at the bottom of the turntable 1 and a mounting plate 2 arranged above the turntable 1, and the base 3 is provided with a central axis 33, The central shaft 33 is installed on the turntable 1, the central shaft does not rotate with the turntable, the base 3 is provided with a first drive motor for driving the turntable 1 to rotate, and the turntable 1 is provided with a plurality of fixed slot 11, the mounting plate 2 is provided with a detection assembly and a drive assembly, and the turntable 1 is provided with a plurality of transmission slots 12 matching with the drive assembly, and the transmission slots 12 are arranged in the fixed slot 11 On the outside, when the drive assembly is embedded in the transmission groove 12, the fixing groove 11 is in a conduction state; after the chip and the circuit board are loaded on the bracket, the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com