Demineralizing, purifying and filtering device in epoxy resin production

An epoxy resin and filtration device technology, which is applied in the field of purification, desalination, and filtration devices, can solve problems such as large energy consumption, and achieve the effects of increasing slag holding space, unique sealing structure, and fast filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

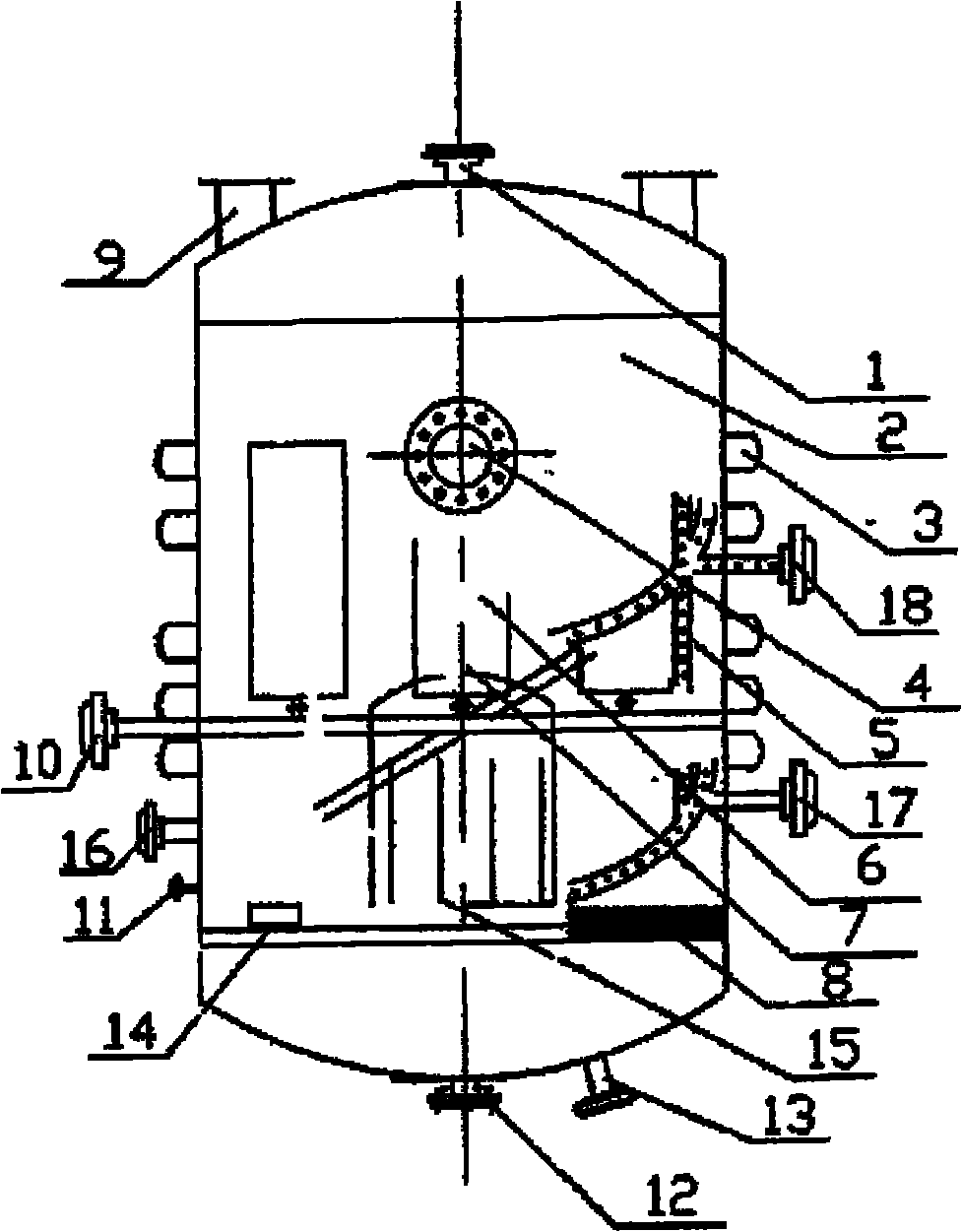

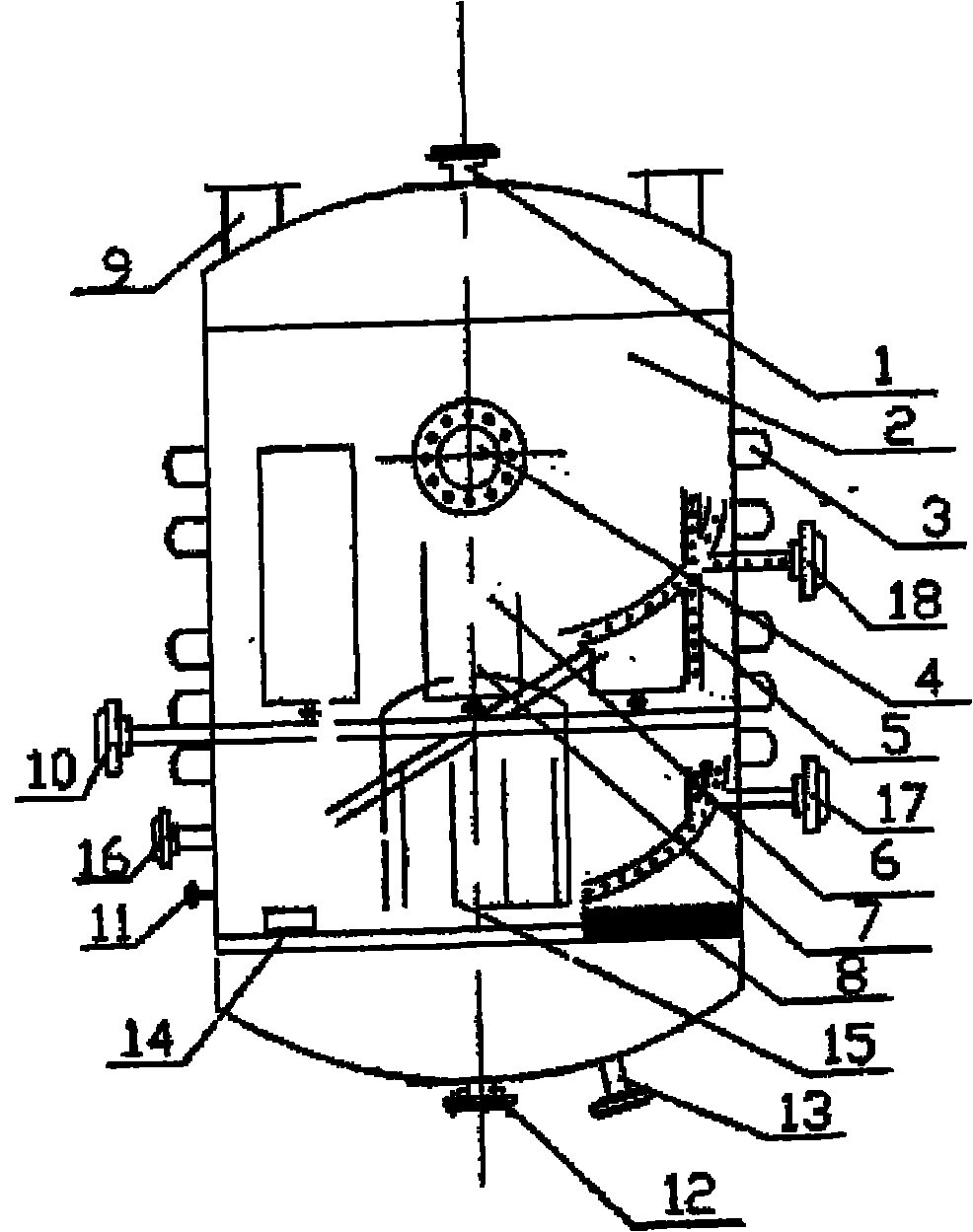

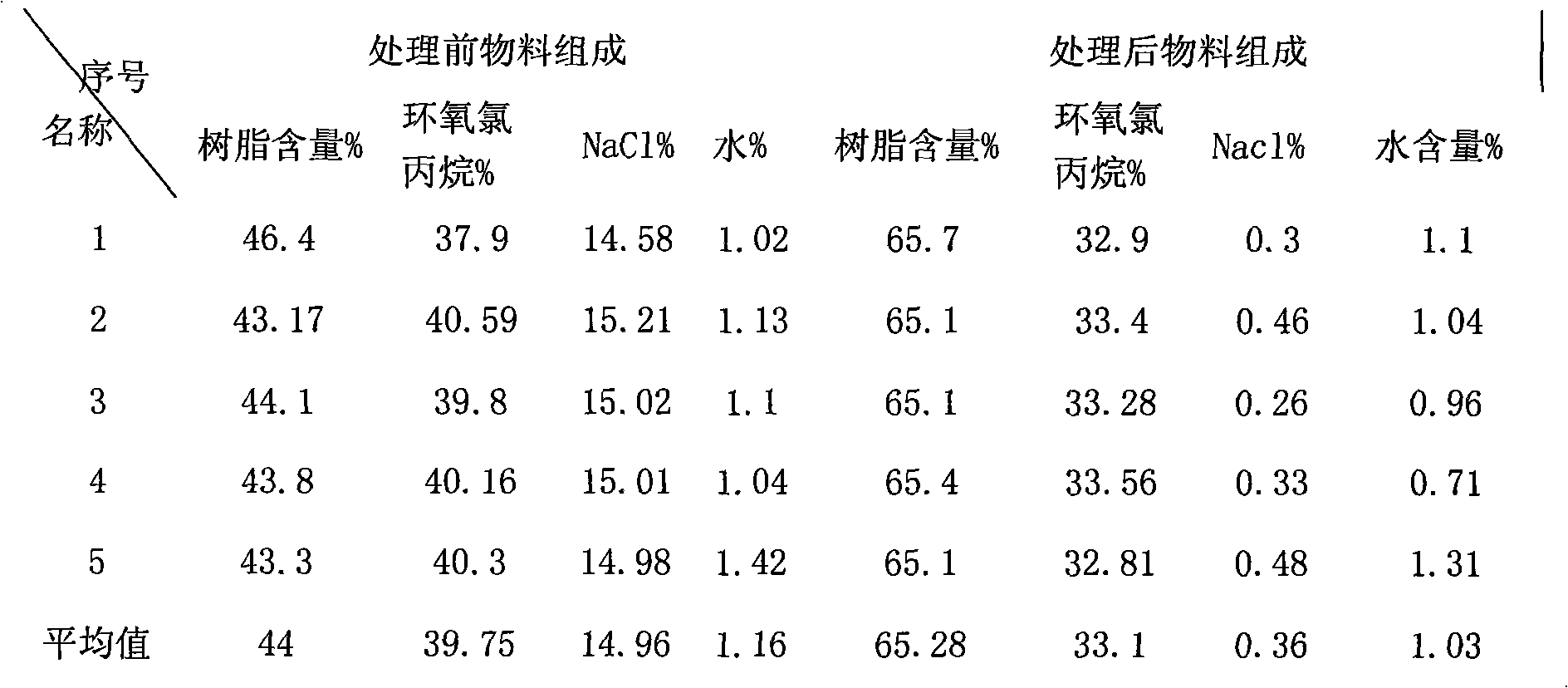

[0047]A desalination, purification and filtration device in the production of epoxy resin, comprising a filter 2, a material inlet 1 is arranged on the upper part of the filter, and a discharge pipe / vacuum interface 12 is arranged on the lower part of the filter (which can also be used as a discharge pipe interface and a vacuum interface ), the filter is provided with upper, middle and lower three sets of filter elements; the first set of filter elements 8 is located at the bottom, in the form of horizontal laying, and the filter medium is laid between two filter plates with holes; the second set of filter elements 6 is located at the first, Above the third set of filter elements, the filter medium is a wax-type filter element, and the wax-type filter element and the first filtrate collecting pipe are connected by flanges, and the first filtrate collecting pipe is connected to the first collecting pipe / vacuum interface 10 on the filter (optional) It also serves as the first col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com