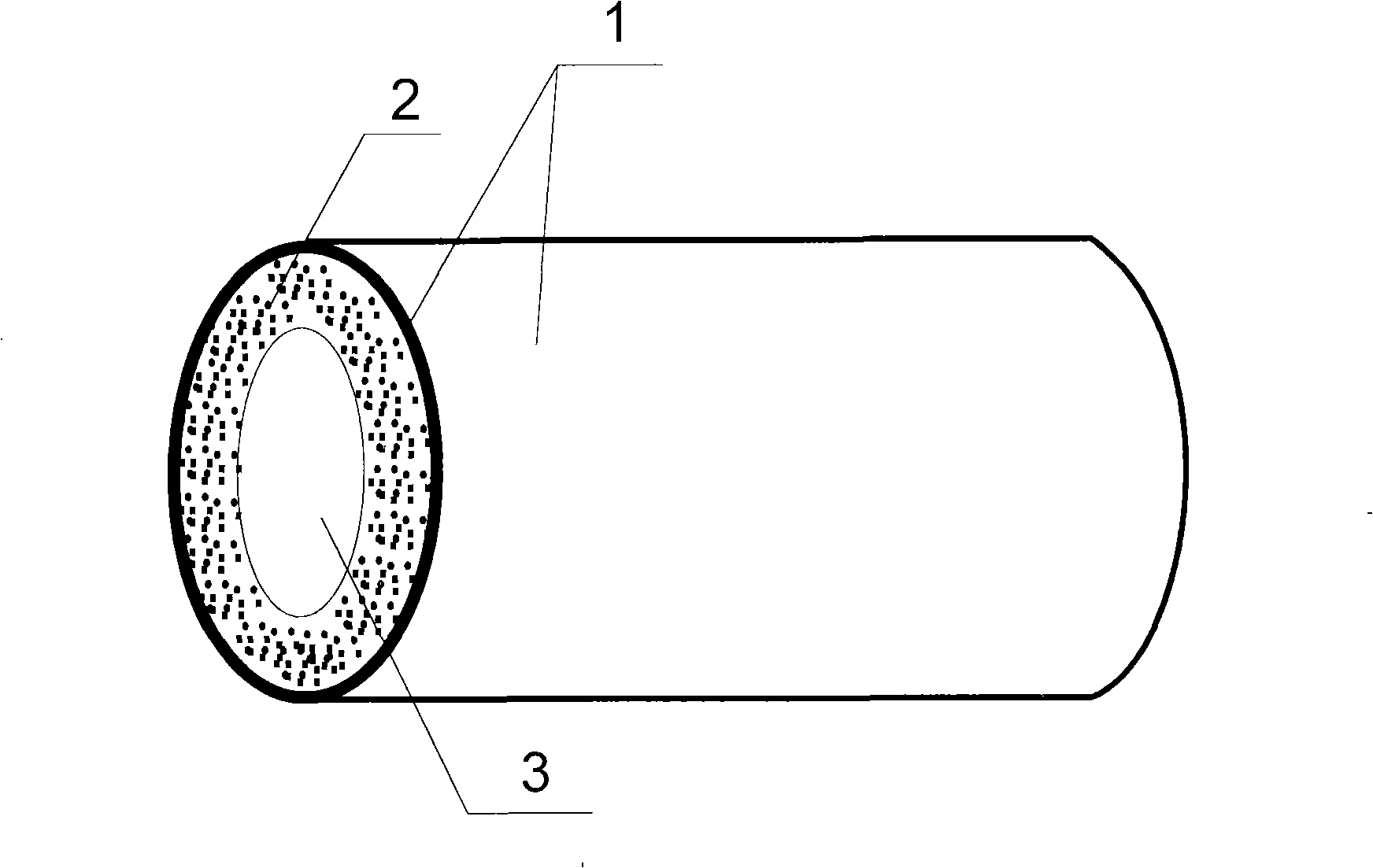

Oxide combined silicon carbide ceramic film tube

A technology of silicon carbide ceramics and oxides, applied in chemical instruments and methods, filtration separation, gravity filters, etc., can solve the problems of compact structure affecting filtration speed, failure to meet filtration requirements, etc., and achieve fast filtration speed and thermal stability Good performance, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

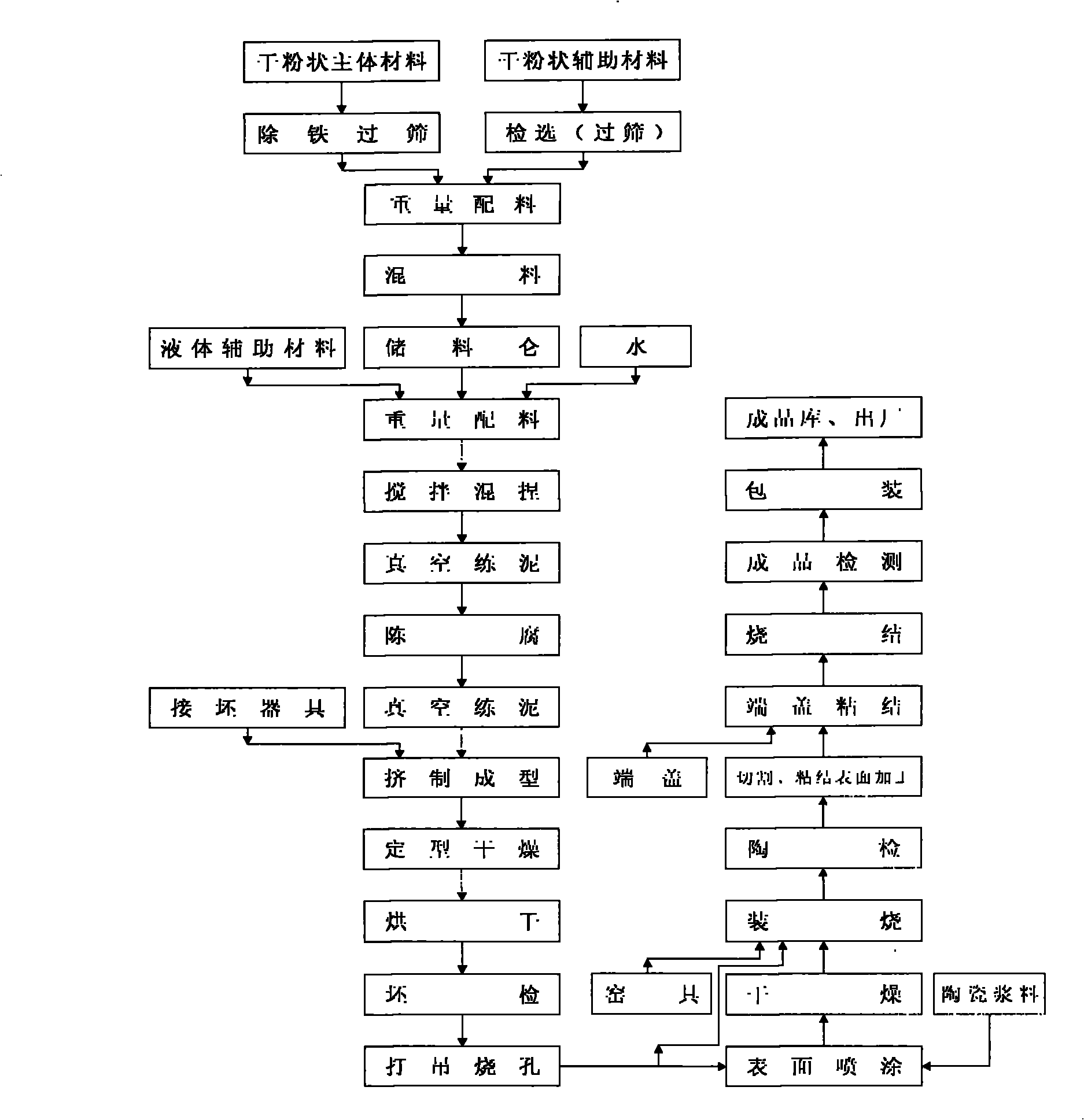

[0017] The first step is to select the raw materials silicon carbide-90, silicon micropowder-6, kaolin-2, silica sol-1, corundum micropowder-1 according to weight components.

[0018] In the second step, the above raw materials are mixed, and then an appropriate amount of water, a surfactant and a plasticizer are used for kneading, and after kneading, aging is carried out, and the aged raw materials are processed into tubular blanks and dried.

[0019] The third step, coating: choose αAl according to the weight component 2 o 3 Micropowder-20; Al(OH) 3 Micro powder - 70; Kaolin powder - 10 After mixing, add hydroxypropyl methylcellulose to make pulp; plate the prepared pulp on the tubular blank, and dry it.

[0020] The fourth step, firing: put the dried coated pipe fittings into the furnace for firing. During firing, gradually increase the temperature and fire according to the heating stage of 550-1400°C, and combine the fired oxide with silicon carbide ceramics After the f...

Embodiment 2

[0022] The first step is to select the raw materials silicon carbide-85, silicon micropowder-7, kaolin-3, metal silicon micropowder-2, charcoal-3 according to weight components.

[0023] In the second step, the above raw materials are mixed, and then an appropriate amount of water, a surfactant and a plasticizer are used for kneading, and after kneading, aging is carried out, and the aged raw materials are processed into tubular blanks and dried.

[0024] The third step, coating: choose αAl according to the weight component 2 o 3 Micropowder--2O; Al(OH) 3 Micro powder - 70; Kaolin powder - 10 After mixing, add hydroxypropyl methylcellulose to make pulp; plate the prepared pulp on the tubular blank, and dry it.

[0025] The fourth step, firing: put the dried coated pipe fittings into the furnace for firing. During firing, gradually increase the temperature and fire according to the heating stage of 550-1400°C, and combine the fired oxide with silicon carbide ceramics After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com