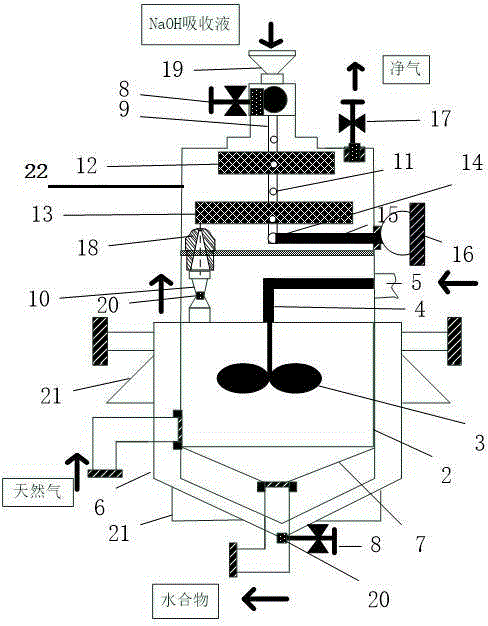

Super-gravity type desulfurization and decarburization device integrating hydrate method and membrane method

A technology of supergravity and hydration, which is applied in the direction of gas fuel, separation methods, chemical instruments and methods, etc., can solve the problems of corroded pipelines and equipment, easy to cause environmental pollution, and difficult to obtain high purity, etc., to achieve high safety and reduce Initial investment cost, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

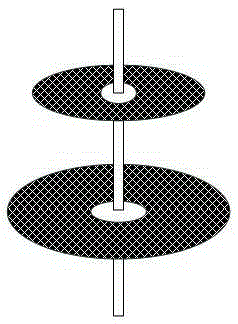

[0032] Its concrete implementation scheme is as follows:

[0033] Under the set pressure, the natural gas vented from the oil field enters the stirred hydrate reactor 2 through the inlet channel 1 at a speed of 1.0~2.5m / s, and at the same time, the solution containing the kinetic accelerator SDS passes through the liquid inlet 5 The annular liquid inlet pipe 4 enters the stirred hydrate reactor 2, wherein the concentration of SDS is controlled within the range of 300~500mg / L, among which 500mg / L is the best; the stirred hydrate reactor adopts external water-cooled jacket refrigeration, That is, the water-cooled jacket 6 is placed in the cavity formed by the double-layer casing to achieve the cooling effect. The temperature of the stirred hydrate reactor is controlled at 0.5~4°C, and the pressure inside the stirred hydrate reactor 2 is controlled at 1 In the range of ~4MPa, after sufficient hydration reaction, the H in natural gas 2 S and CO 2 Wait for the acid gas to be soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com