Refining method of virgin gas containing ethane used in process for preparing ethylbenzene by ethane

A refining method and raw gas technology, applied in ethylene production, chemical instruments and methods, petroleum industry, etc., can solve the problems of discontinuity, waste of pretreatment resources, etc., achieve simple process, low ethylene loss rate, and improved ethylene yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

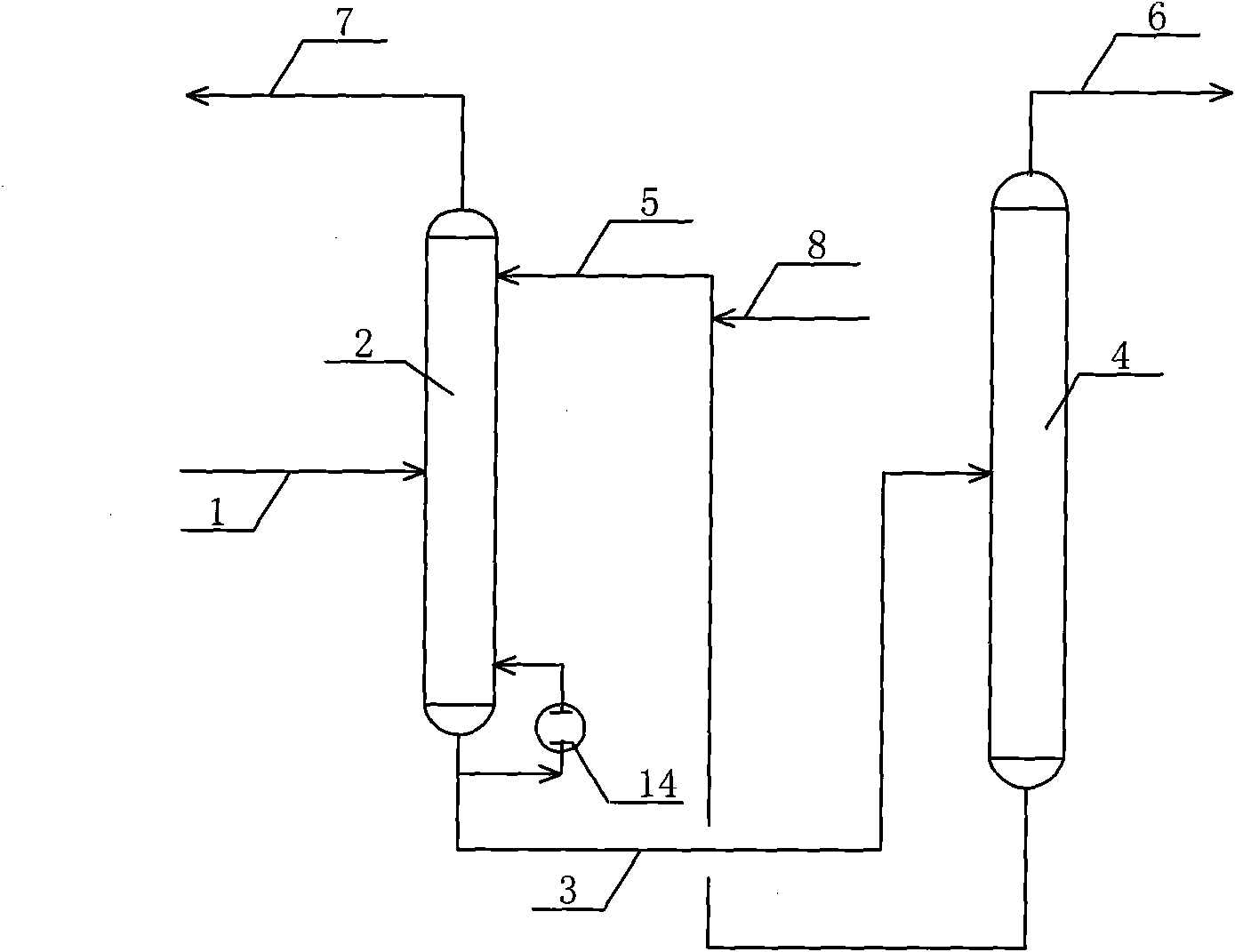

[0034] A specific embodiment of the present invention is as figure 1 As shown, the ethylene-containing feed gas 1 enters from the middle of the absorption tower 2, and the desorbed absorbent 5 enters from the upper part of the absorption tower 2, and the ethylene-containing feed gas 1 and the desorbed absorbent 5 are countercurrently contacted, and the operation of the absorption tower 2 The temperature is -20-300°C, the pressure is 0.1-5.0MPaG, and the ethylene-containing raw material gas 7 absorbed by the absorbent enters the reaction part of the ethylbenzene device; the bottom of the absorption tower 2 is equipped with a reboiler 14, and the saturated absorbent 3 Enter the middle section of the desorption tower 4 for desorption, the pressure is 0.001-4.0MPaG, the temperature is 10-300°C, the absorbent 5 desorbed at the bottom of the tower is returned to the absorption tower 2 for recycling, and supplementary absorbent 8 is added according to the consumption of the absorbent....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com