Composite catalyst for NH3-SCR reaction and preparation method and application thereof

A composite catalyst and ion exchange reaction technology, applied in the field of environmental pollution control, can solve problems such as poor HC poisoning ability, poor hydrothermal stability, and narrow temperature operating window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Its preparation method comprises the following steps:

[0059] (1) AEI molecular sieve is mixed with transition metal salt solution to carry out ion exchange reaction to obtain a mixed solution;

[0060] (2) The mixed solution obtained in step (1) is subjected to solid-liquid separation to obtain a solid mixture;

[0061] (3) Calcining the solid mixture obtained in step (2) to obtain an AEI molecular sieve catalyst.

Embodiment 1

[0064] This example provides a method for NH 3 -AEI molecular sieve catalyst for SCR reaction and its preparation method and application, the AEI molecular sieve catalyst uses AEI molecular sieve as a carrier, and ion-exchange metal copper as an active component.

[0065] Its preparation method is:

[0066] (1) Prepare 0.1mol / L copper sulfate solution, mix aluminum-rich AEI molecular sieve with copper sulfate solution, wherein the mass ratio of AEI molecular sieve to copper sulfate solution is 1g:80mL, stir at 25°C for 12h for ionization exchange reaction to obtain a mixed solution;

[0067] (2) The mixed solution obtained in step (1) is suction filtered and washed 3 times to obtain a filter cake;

[0068] (3) Put the filter cake obtained in step (2) into an oven and dry it at 100°C for 12h, then bake it at 550°C for 5h in a muffle furnace to obtain a powdered Cu-AEI catalyst with an AEI configuration. The obtained catalyst is pressed into tablets, crushed, sieved, and 20-4...

Embodiment 2

[0075] This example provides a method for NH 3 -AEI molecular sieve catalyst for SCR reaction and its preparation method and application, the AEI molecular sieve catalyst is supported by AEI molecular sieve, and metal copper is loaded as an active component.

[0076] Its preparation method is with reference to the preparation method in Example 1, difference is: the copper nitrate solution of preparation 0.3mol / L in the step (1), and the quality of AEI molecular sieve and the volume ratio of copper nitrate solution are 1g:50mL, at 50 Stirring at ℃ for 8h for ion exchange reaction.

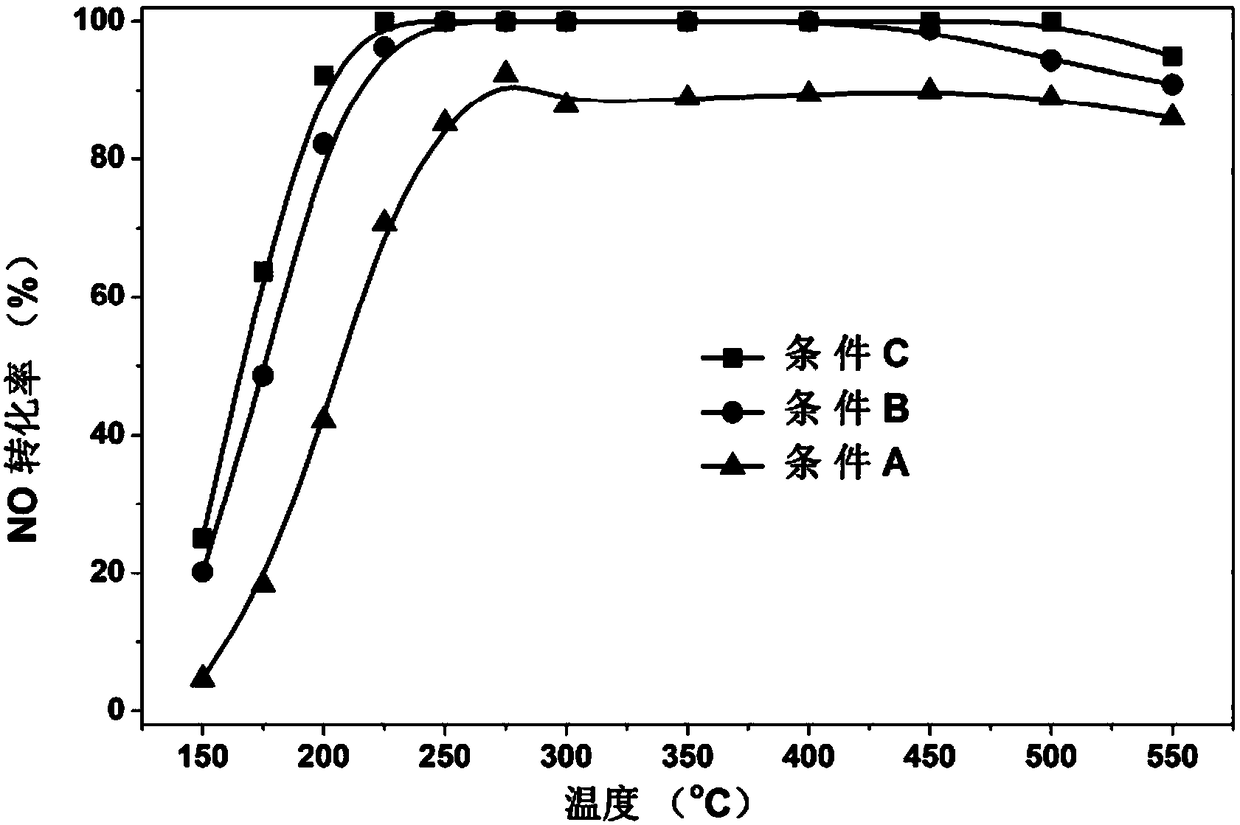

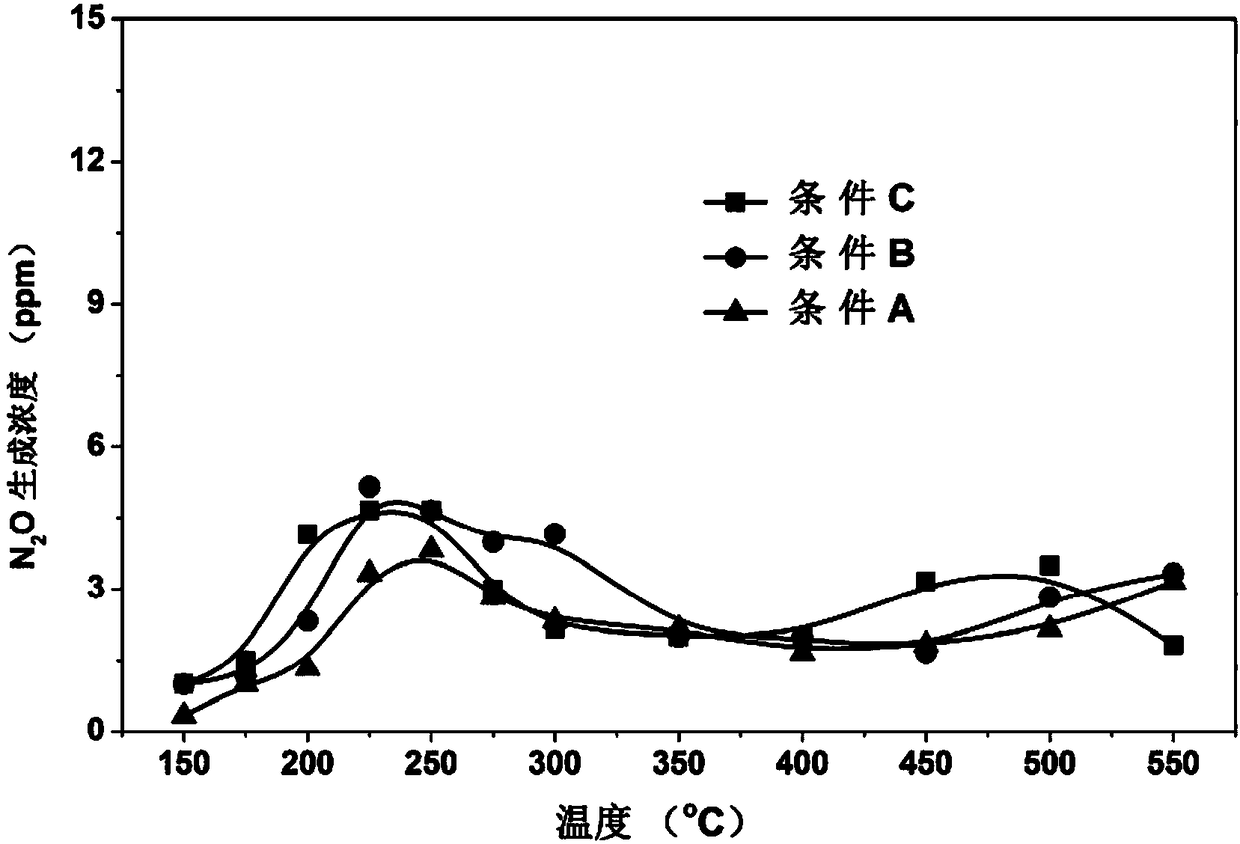

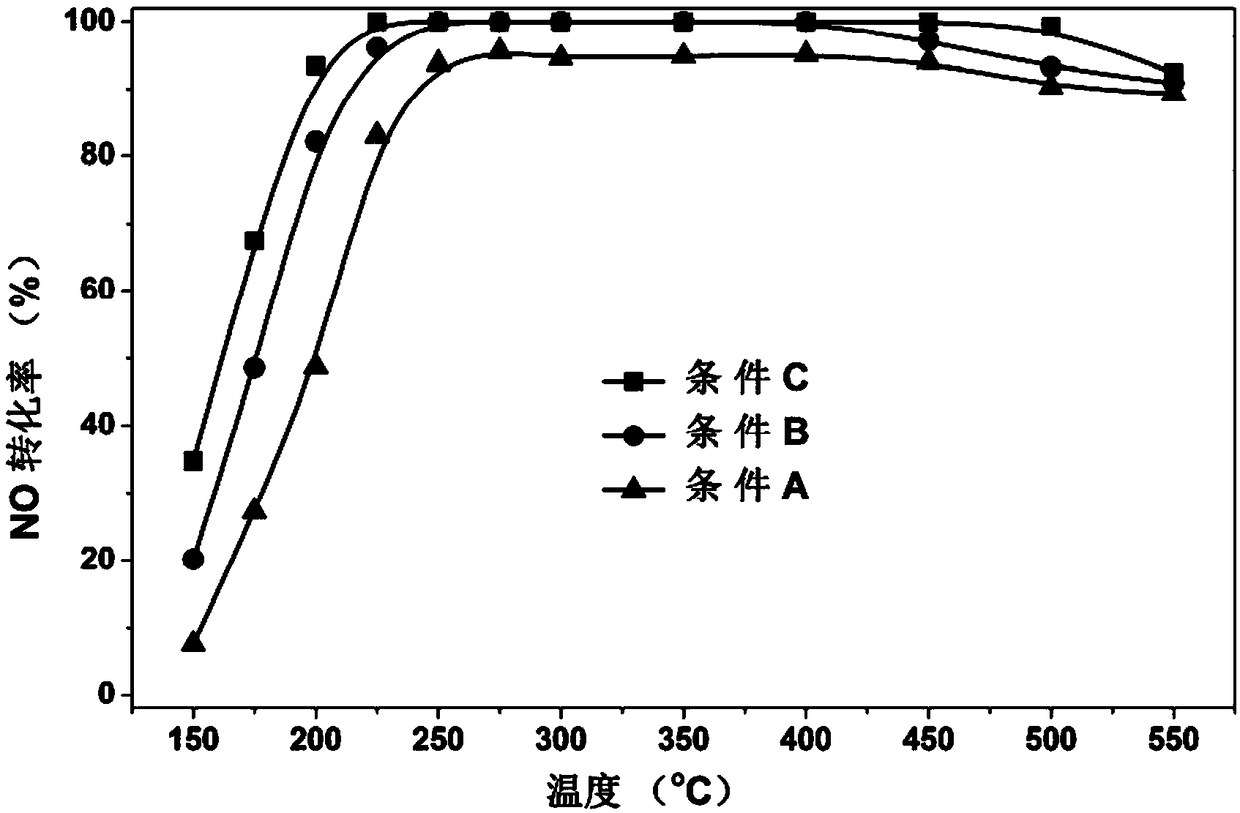

[0077]The resulting Cu-AEI catalyst was used for NH 3 -SCR reaction, its reaction conditions are the same as those in Example 1, and its catalytic activity testing method is the same as in Example 1. In the three test cases of A, B and C, the catalytic activity of the catalyst is as follows image 3 Shown, N 2 The amount of O produced is as Figure 4 shown.

[0078] Depend on image 3 and F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com