Reclaimed rubber or reclaimed-rubber-doped rubber or rubber-plastic composition product and production method thereof

A composition and rubber technology, applied in the connotation field, can solve the problems of contradictory, primary level, and no recycled rubber products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

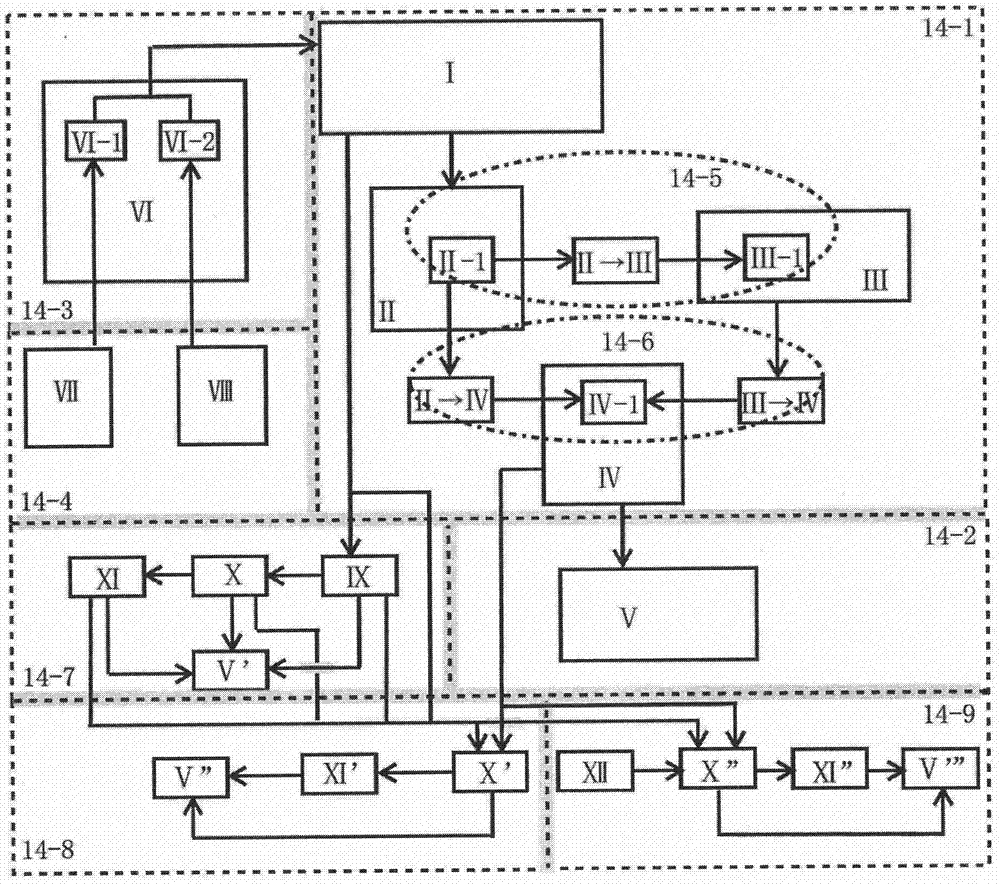

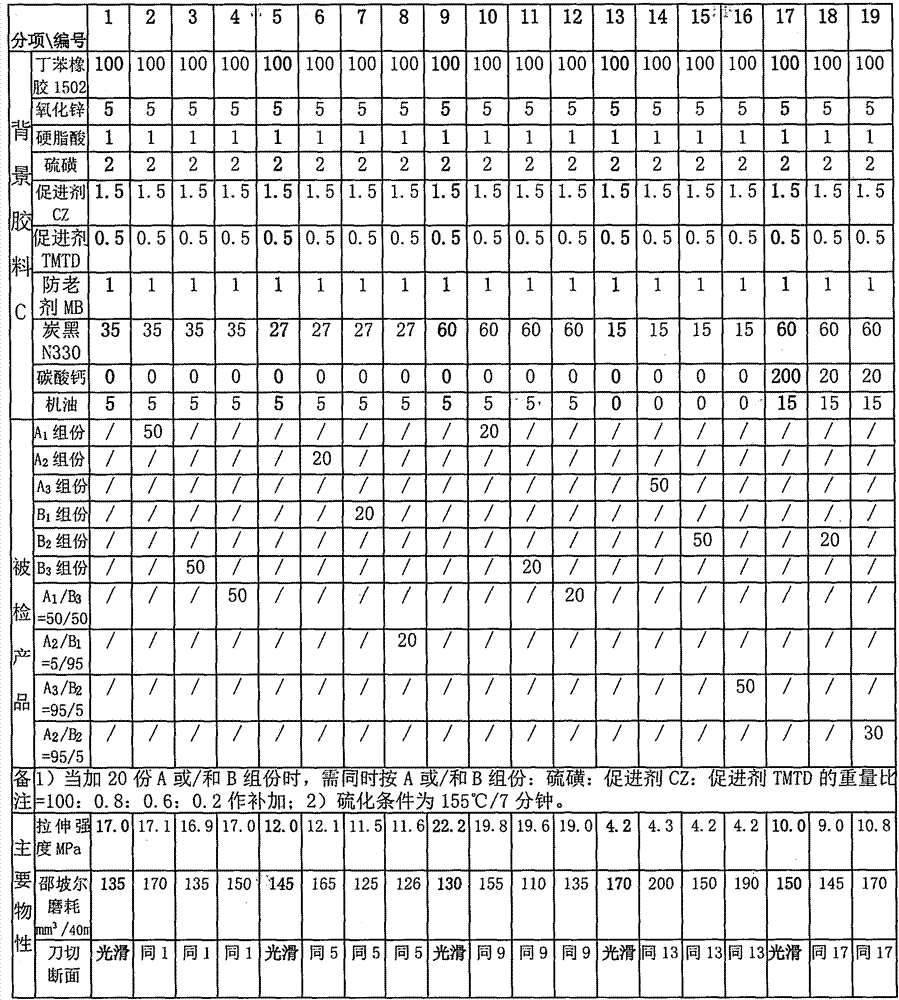

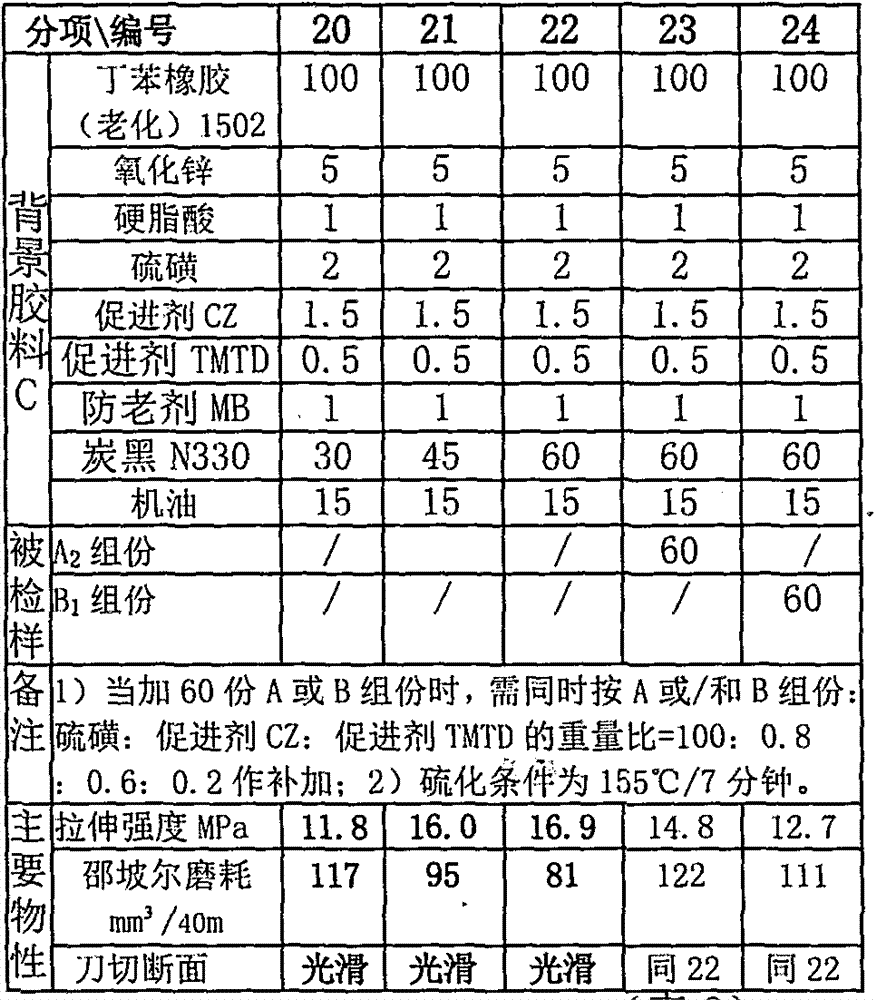

[0110] Embodiment 1. A kind of regenerated rubber or the rubber or rubber-plastic composite product described in it can relate to "after passing through the frozen fine grinder once or passing through the normal temperature elastic body fine grinder once, the obtained must be at least more than 90% Group A obtained through the 60-mesh sieve and having more than or equal to 50% by weight of fine rubber powder or crushing aids passed through the 100-mesh sieve, and then graded, without pollution Part, B component, or / and the composite composition of A / B component, or / and the rubber or rubber-plastic composite composition mixed with A or / and B component, characterized in that: the characteristics of A component include the following 1-1 to 1-3 or any combination of 1-5, 1-7 or the above, the characteristics of component B include the following 1-1 to 1-2 and 1-4 or and 1-6, 1 -A combination of any or more of the above, the characteristics of the A / B component composite compositio...

Embodiment 2

[0140] Embodiment 2. The preparation method of component A and component B of the present invention is mainly characterized in that: all "go through a normal temperature elastomer fine grinder or a frozen fine grinder once, and after being finely crushed through the machine, a lot of 90% by weight of 60 mesh sieve and more than 50% by weight of 100 mesh sieve fine rubber powder or as a crushing aid "this intermediate mixed material, and then separated operation and subsequent treatment Obtain component A of the plasticized material in any form of butter, micellar, granular, continuous sheet, or strip, and component B in the form of powder, flakes, or granules; The "A component" has the following 2-5 to 2-6 or any combination of the above features in 2-1 to 2-4, and the "B component" has the following 2-5 and 2-7 or a combination of any or more of the features from 2-1 to 2-4:

[0141] 2-1. Its rubber material belongs to the combination of waste rubber described in embodiment ...

Embodiment 3

[0162] Embodiment 3. The preparation of the A / B component compound composition of the present invention is characterized in that it also includes: the A component described in Example 1, and the B component described in Example 1, by A / B weight Any ratio in the range of 95 / 5 to 5 / 95 is pre-mixed, and the mixing method includes any or a combination of stirring, banburying, rolling, extrusion, and attention should be paid not to heat during mixing; Depending on the weight ratio of A / B, A / B can be stored in the form of powder, granule, flakes, cake powder, micelles, film, or strips, or any combination of the above. Composite material of components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com