Biopharmaceutical production process continuous sterilization automatic control system and technological process thereof

An automatic control system and production process technology, applied in the direction of toilet sanitary equipment, water supply equipment, heating, etc., can solve the problem of in-depth research on continuous sterilization automatic control technology, cannot guarantee the consistency of batch production quality, and cannot meet the needs of production enterprises Production requirements and other issues to achieve the effect of saving raw materials, reducing human participation factors, and shortening heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

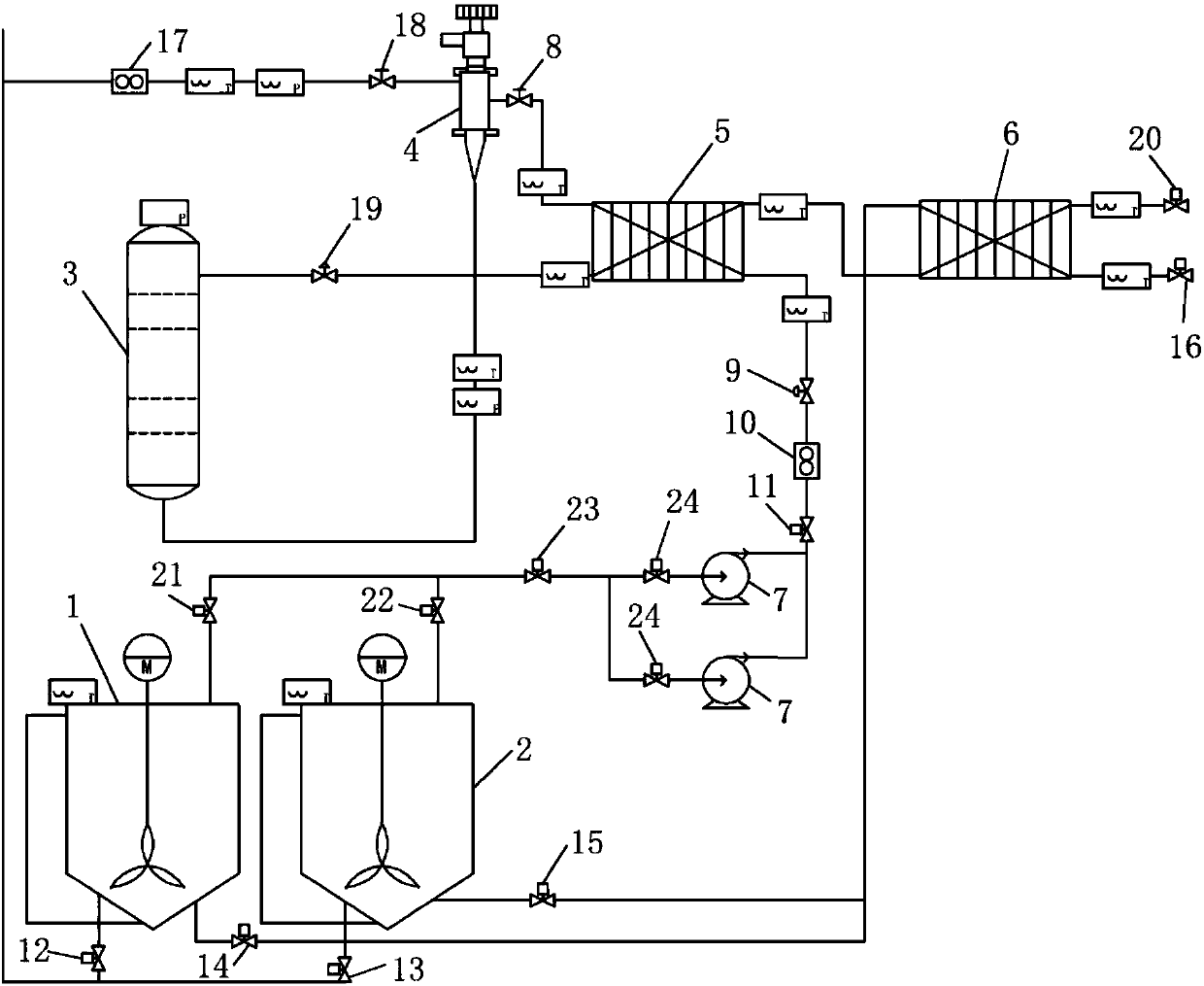

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 As shown, a continuous sterilization automatic control system for biopharmaceutical production process, which includes the first batching tank 1, the second batching tank 2, the maintenance tank 3, the steam ejector 4, the primary heat exchanger 5 and the secondary heat exchange Device 6; steam ejector 4, maintenance tank 3, primary heat exchanger 5 and secondary heat exchanger 6 are connected sequentially through pipelines, and steam ejector 4, first batching tank 1 and second batching tank 2 are connected sequentially through pipelines , two lift pumps 7 are connected between the steam injector 4 and the second batching tank 2, and a cut-off check valve 8, a temperature sensor, and a material regulator are sequentially connected between the steam injector 4 and the two lift pumps 7. Valve 9, material flow meter 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com