Ceramic diaphragm for in-situ generation of composite binder, and preparation method and application of ceramic diaphragm

An in-situ generation, ceramic diaphragm technology, applied in structural parts, electrochemical generators, electrical components, etc., can solve the problems of unfavorable industrial application of diaphragms, increased cost of diaphragms, and high price of dopamine in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

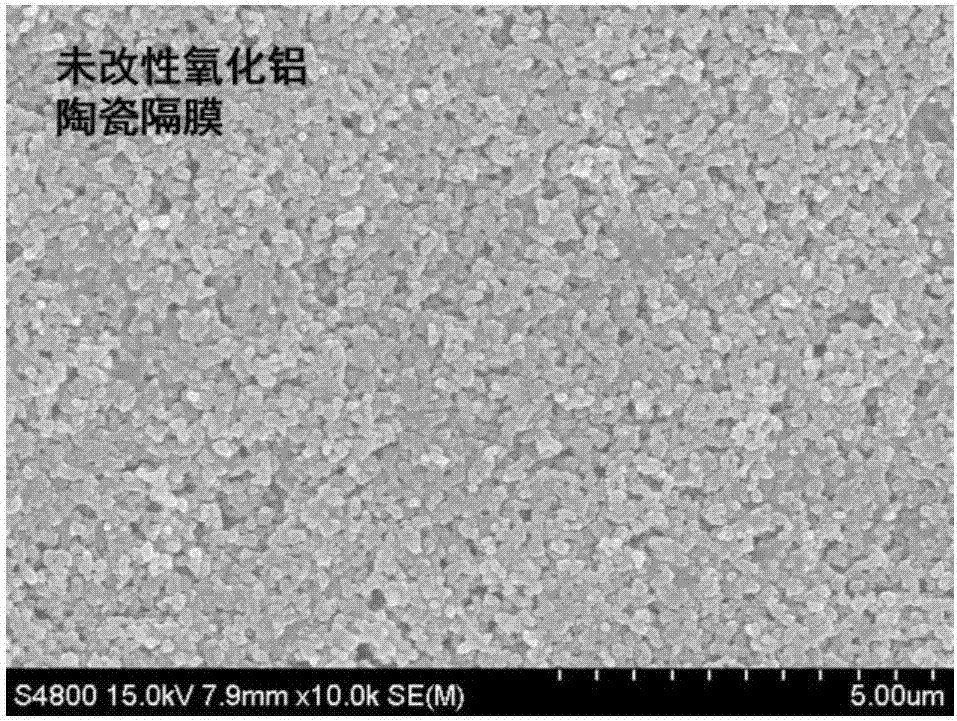

[0068] Example 1: Preparation of a ceramic separator with an in-situ composite binder and its application in lithium-ion batteries

[0069] Preparation of Ceramic Separators with Composite Binders:

[0070] Disperse aluminum oxide powder with a particle size of 100-200nm and a binder (styrene-butadiene rubber (SBR) and carboxymethyl cellulose (CMC) system) in a solvent, and mix thoroughly to form a ceramic slurry. Wherein, the mass ratio of each component is: aluminum oxide / SBR / CMC=95 / 3 / 2. The solvent used in present embodiment 1 is to use the water / ethanol that volume ratio is 1:1 to be solvent, and configuration pH is the 10mmol / L Tris / hydrochloric acid pH buffer solution of 8.5, and the mass ratio of liquid-solid is 90%:10%.

[0071] After the ceramic slurry is evenly mixed, catechol is dissolved in the ceramic slurry so that its concentration is 20mmol / L, and the molar ratio is: catechol / tetraethylenepentamine=4 / 1, and a quantitative amount of Tetraethylenepentamine. S...

Embodiment 2

[0081] Example 2: Preparation of a ceramic separator with an in-situ composite binder and its application in lithium-ion batteries

[0082] Preparation of Ceramic Separators with Composite Binders:

[0083] Disperse silica balls with a particle size of 200nm and a binder (gelatin and polyvinyl alcohol (PVA) system) in a solvent, and mix thoroughly to make a ceramic slurry, wherein the mass ratio of each component is: silica / gelatin / PVA=90 / 4 / 6. The solvent used in the present embodiment 2 is that water / methanol with a volume ratio of 1:1 is a solvent, and configuration pH is a 10mmol / L tris / hydrochloric acid pH buffer solution of 12, and the mass ratio of liquid to solid is 90%:10%.

[0084] After the ceramic slurry is evenly mixed, dissolve pyrogallol in the ceramic slurry so that its concentration is 200mmol / L, and the molar ratio is: pyrogallol / polyethyleneimine with a molecular weight of 600=10 / 1 , adding quantitative polyethyleneimine. Stir to fully dissolve and mix t...

Embodiment 3

[0091] Example 3: Preparation of a ceramic separator with in-situ composite binder and its application in lithium-ion batteries

[0092] Preparation of Ceramic Separators with Composite Binders:

[0093] Disperse titanium dioxide powder with a particle size of 300nm and a binder (polyacrylate terpolymer latex (LA132, LA133) system) in a solvent, and mix them thoroughly to form a ceramic slurry. The mass ratio of each component It is: titanium dioxide / LA132 / LA133=85 / 6 / 9. The solvent used in the present embodiment 3 is that water / acetone with a volume ratio of 1:1 is a solvent, and configuration pH is 10mmol / L tris / hydrochloric acid pH buffer solution, and the mass ratio of liquid to solid is 90%:10%.

[0094] After the ceramic slurry is evenly mixed, tannic acid is dissolved in the ceramic slurry so that its concentration is 2mmol / L, and the molar ratio is: tannic acid / phenylethylamine=1 / 5, and a quantitative amount of phenylethylamine is added . Stir to fully dissolve and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com