Response surface method-based UV/H2O2 process parameter optimization method

A technology of process parameter optimization and response surface method, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as difficult to determine economical and effective process parameters, and does not consider economic factors , to achieve the effect of automatic adjustment and simplification of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

[0022] The present invention is based on the UV / H of the response surface method 2 o 2 Process parameter optimization method, comprises the steps:

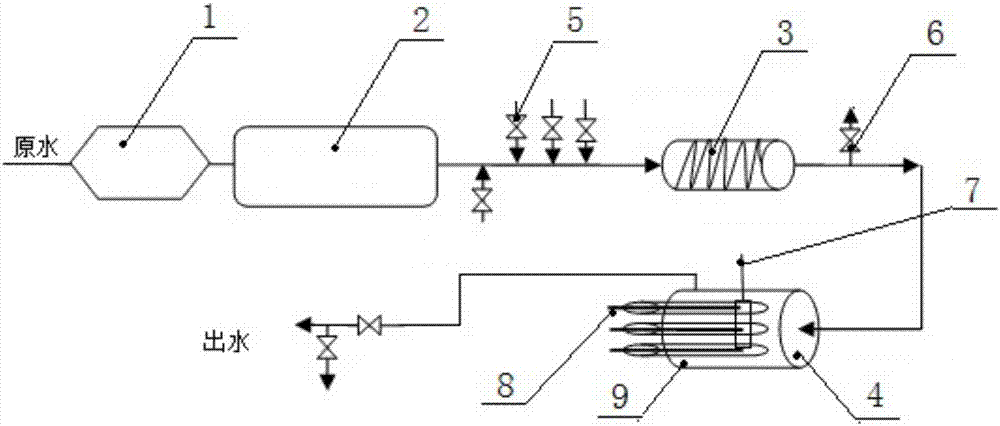

[0023] (1) Design the RSM mixed standard experiment for the removal of target organic matter: using matching UV / H 2 o 2 Carry out experiments in the advanced oxidation pilot plant; establish target organic matter removal models one by one and test their significance and effectiveness, and analyze their respective optimal process parameters; optimize the design of the best working conditions for the removal of various target organic compounds, and conduct model verification to determine the economic Effective process parameters;

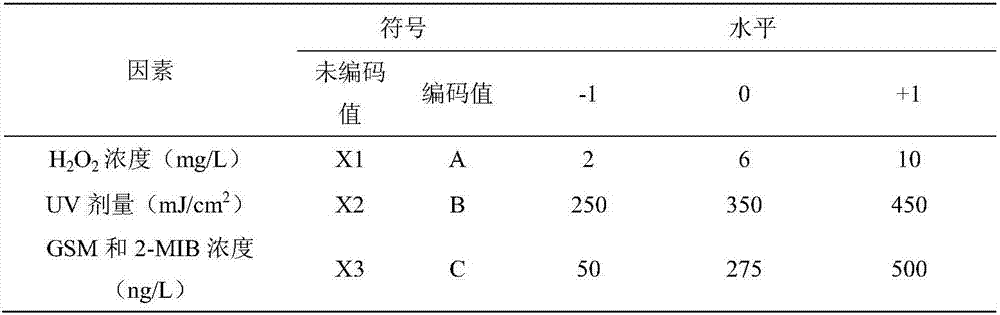

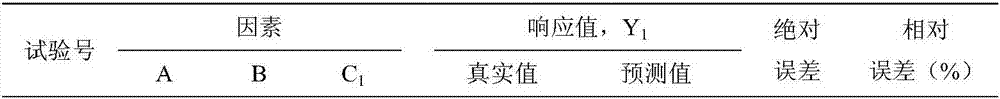

[0024] (2) RSM mixed standard experiment of described target organic matter removal: for H 2 o 2 Dosing amount, UV dose, initial concentration of target organic matter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com