Printing and dyeing waste water treatment method based on film technology

A technology for printing and dyeing wastewater and its treatment method, which is applied in the field of printing and dyeing wastewater for reuse of reclaimed water. It can solve the problems of unsatisfactory COD removal, long process flow, and difficulty for microorganisms to adapt to printing and dyeing wastewater, so as to overcome the unsatisfactory wastewater treatment effect and overcome the The effect of high cost of adsorption treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

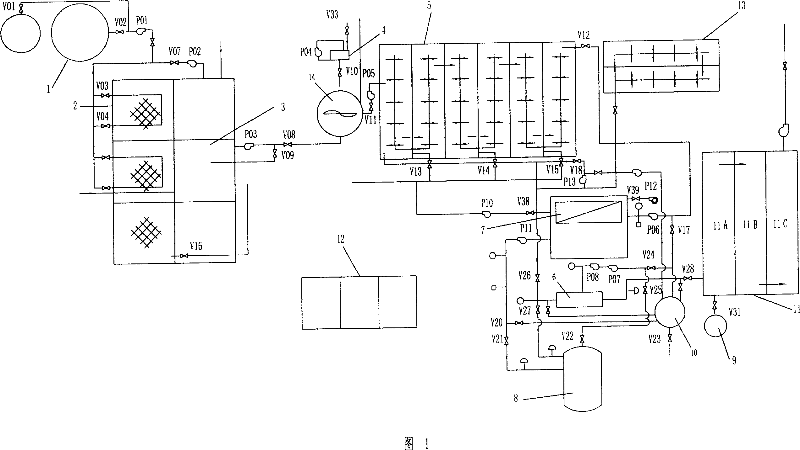

[0028] Fig. 1 provides the technological process schematic diagram of the embodiment of the present invention, and the present invention completes the treatment process design of its printing and dyeing wastewater after carrying out in-depth systematic comparative research on the composition, properties and existing treatment schemes of the printing and dyeing wastewater, and the waste water passes through the grid waste water 7 units are used in combination, including regulating tank, flocculation mixing reaction tank, settling tank, membrane bioreactor circulation unit, reverse osmosis circulation unit, adsorption decolorization unit and system electrical control unit. Thereby forming a printing and dyeing wastewater treatment method and device which are especially suitable for the printing and dyeing wastewater which is difficult to reach the standard according to the conventional sewage treatment method.

[0029] The printing and dyeing wastewater and domestic wastewater st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com