Dyeing and finishing process for sea silk fabric

A seaweed fiber and process technology, applied in the field of textile printing and dyeing, can solve the problems of high energy consumption, long process flow, waste water pollution, etc., and achieve the effects of good drape, soft fabric feel, and shortened processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

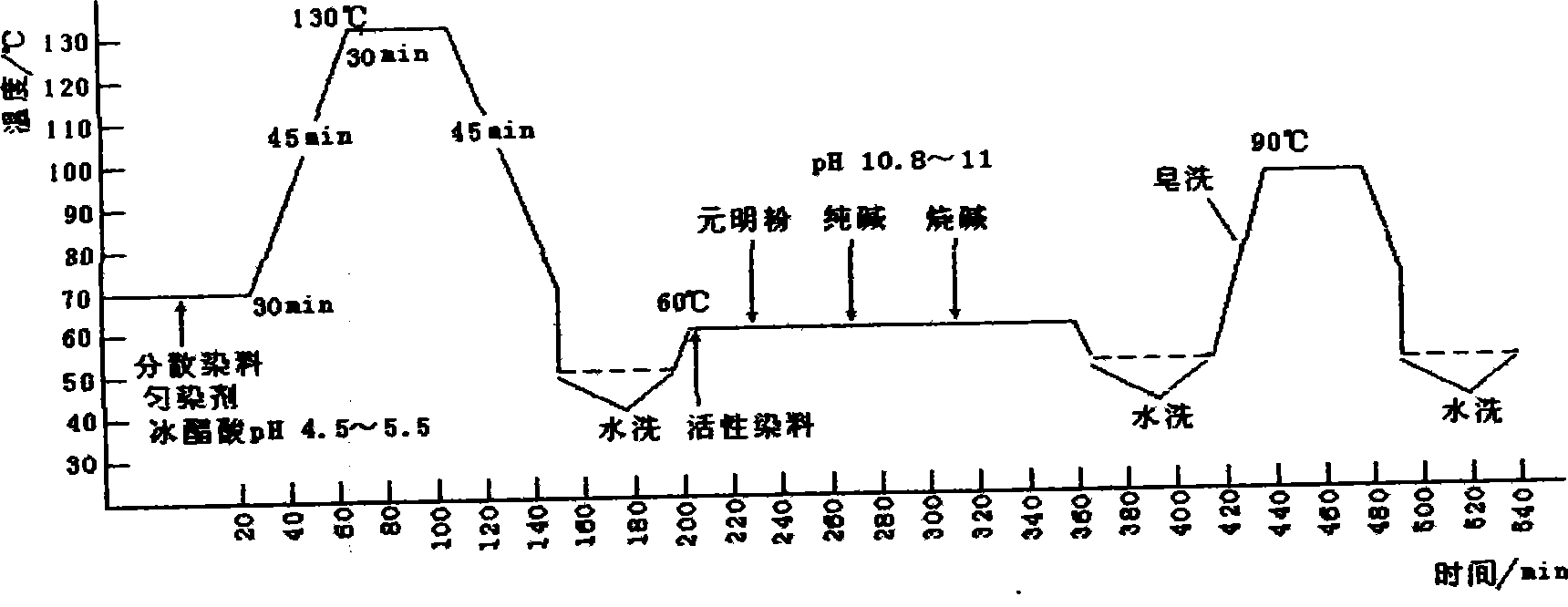

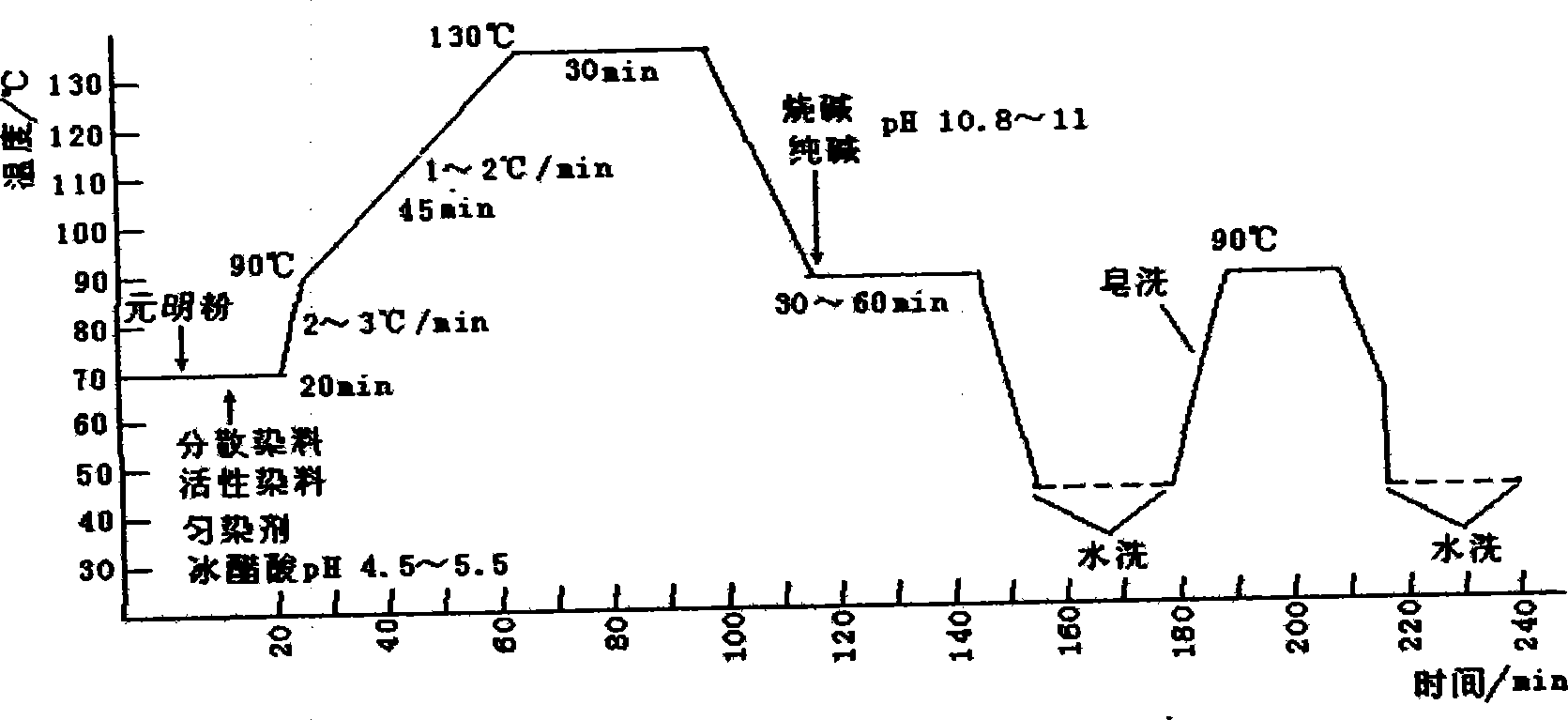

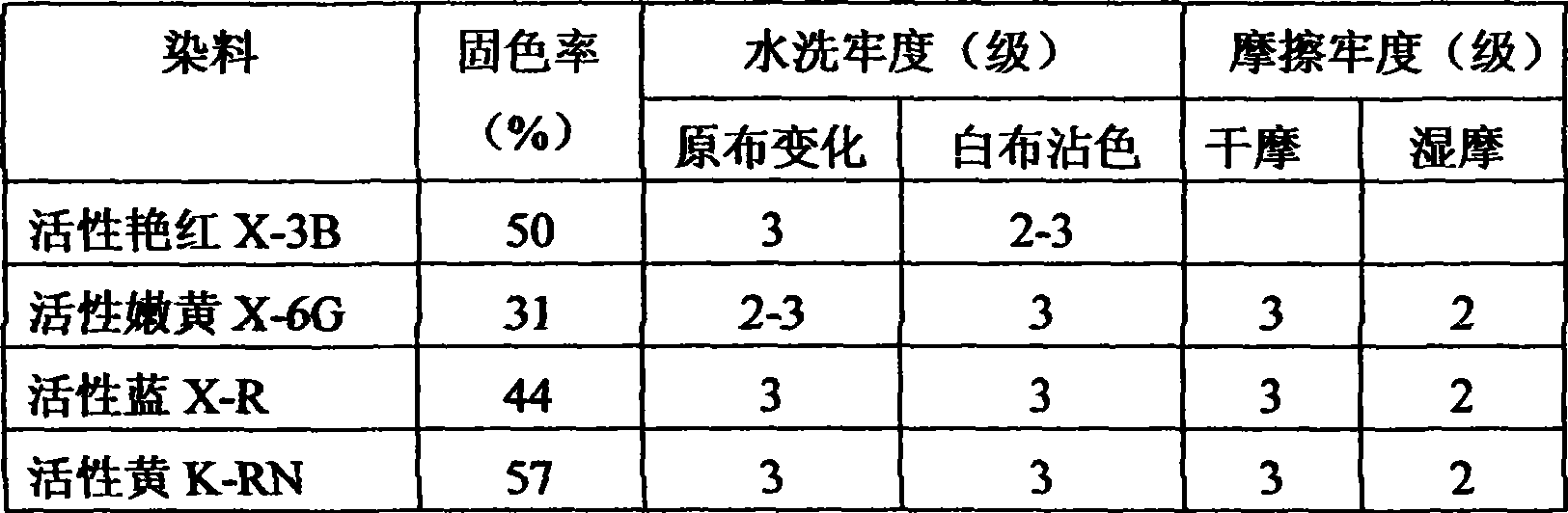

[0023] The dyeing and finishing process steps of the seaweed fiber fabric of the present invention include: pretreatment-dyeing-after-finishing process, specifically as follows:

[0024] 1. Pretreatment

[0025] 1.1. Process flow: Enzyme-oxygen descouring and bleaching one-bath treatment process: immersion in processing fluid-boiling and bleaching (70-100°C, 30-60min)-hot water washing (80°C, twice)-cold water wash

[0026] 1.2. Put the fabric into the dyeing vat with a bath ratio of 1:5 to 1:30 at room temperature, add 1 to 3% of multifunctional scouring enzyme 10A type and 2 to 10% of hydrogen peroxide (27%) according to the weight percentage of the fabric, and then heat to Boil and bleach at 70-100°C, keep warm for 30-60 minutes, wash and prepare for dyeing.

[0027] 1.3. Pretreatment results and analysis of different process conditions

[0028] 1.3.1. Enzyme dosage

[0029] Carry out above-mentioned pretreatment test respectively by the enzyme consumption described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com