Preparation method of organic silicon defoaming agent used for textile printing and dyeing

A silicone defoamer, textile printing and dyeing technology, applied in the field of emulsification technology, can solve the problems of large amount of stabilizer, poor applicability, poor defoaming performance, etc., and achieve excellent defoaming performance and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

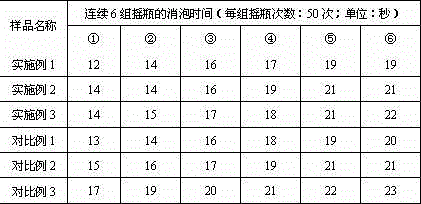

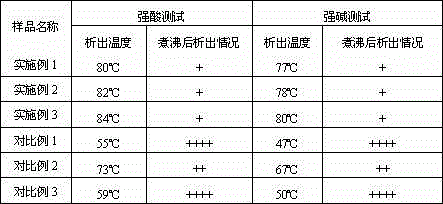

Examples

Embodiment 1

[0038] Mix 20g of silicone composition, 5g of D420 and 0.0015g of dibutyltin dilaurate evenly, raise the temperature to 160°C, and stir at 1000rpm for high-speed dispersion for 1.5h; adjust the speed of the agitator to 250rpm, turn off the heating, and cool down to 80°C. Mixture G1 is obtained. Add 2g of S113, 2.5g of Span-80, and 2.5g of Tween-80 into 20g of water, raise the temperature to 80°C, stir and mix for 15min to obtain mixture H1. Then slowly add mixture H1 to mixture G1, keep stirring, and emulsify at 80°C for 0.5h; then homogenize the above mixture through a colloid mill, and finally dilute with 3g polyacrylate thickener and 40g water to obtain silicone defoamer.

Embodiment 2

[0040] Mix 18g of silicone composition, 9g of D903 and 0.003g of stannous octoate evenly, raise the temperature to 140°C, stir at 1200rpm for high-speed dispersion for 1h; adjust the speed of the stirrer to 300rpm, turn off the heating, and cool down to 75°C to obtain the mixture G2 . Add 6g of S82, 5g of Span-85, and 5g of A-105 into 25g of water, raise the temperature to 75°C, stir and mix for 15min to obtain mixture H2. Then slowly add mixture H2 to mixture G2, keep stirring, and emulsify at 75°C for 1 hour; then homogenize the above mixture through a colloid mill, and finally dilute it with 2g of polyacrylate thickener and 30g of water to obtain a silicone paste foaming agent.

Embodiment 3

[0042] Mix 19g of silicone composition, 9g of D903 and 0.014g of dibutyltin diacetate evenly, raise the temperature to 120°C, stir at 1500rpm for high-speed dispersion for 1h; adjust the speed of the stirrer to 280rpm, turn off the heating, and cool down to 70°C to obtain a mixture G3. Add 6g of S610 and 1g of OP-10 into 30g of water, raise the temperature to 70°C, stir and mix for 15min to obtain mixture H3. Then slowly add mixture H3 to mixture G3, keep stirring, and emulsify at 70°C for 2 hours; then homogenize the above mixture through a colloid mill, and finally dilute with 0.1g polyacrylate thickener and 34.9g water to obtain organic Silicon defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com