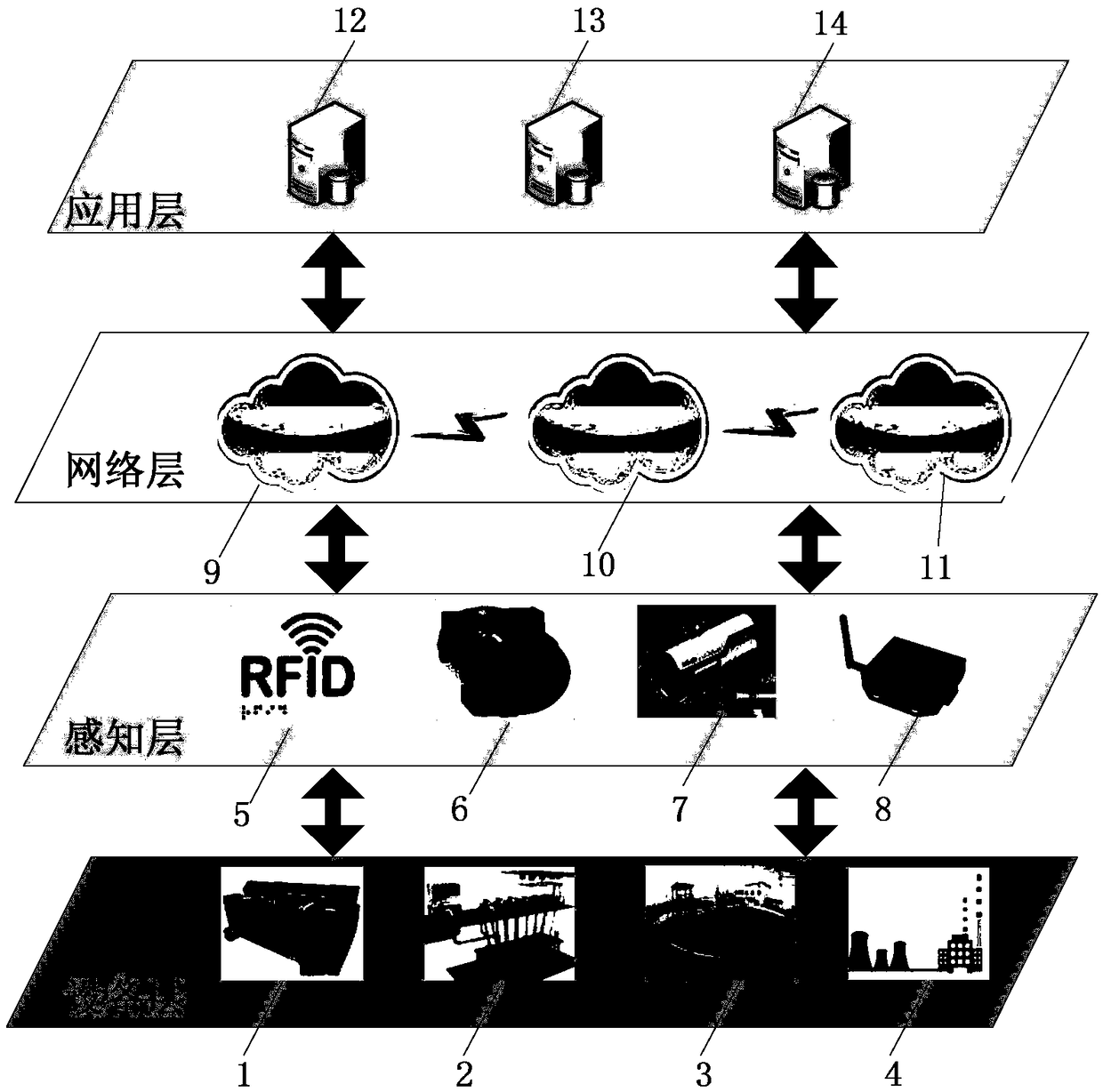

A system architecture of a digital factory in the textile printing and dyeing industry

A textile printing and dyeing and factory technology, applied in the field of digital factory system architecture in the textile printing and dyeing industry, can solve the problems of insufficient depth of data analysis and application, weak overall planning of digital factories, and low level of digitalization, so as to promote lean production and improve The effect of comprehensive network coverage and elimination of information islands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Such as figure 1As shown, the overall structure diagram of the digital factory in the textile printing and dyeing industry of the present invention is provided, through the RFID tag 5, the field instrument 6 (including the required PLC, flow meter, pressure gauge and density meter, etc. in the textile printing and dyeing production process), the field Camera 7 (including the production camera and security camera required in the textile printing and dyeing production process) and sensor 8 (including the temperature sensor, liquid level sensor, and pH sensor required in the textile printing and dyeing production process) and other sensing methods to obtain information during the production process Production equipment 1 (including looms, dyeing machines, drawing machines and finishing equipment required in the production process of textile printing and dyeing), logistics equipment 2 (including weighing, batching and feeding equipment required in the production process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com