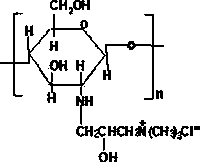

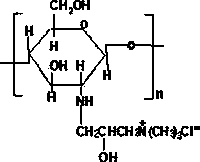

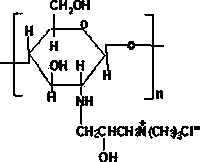

Preparation method of quaternary ammonium salt chitosan and organic silicon composite modified cationic water-based polyurethane fixing agent

A technology of quaternary ammonium chitosan and water-based polyurethane, which is applied in dyeing, textiles and papermaking, and can solve problems such as poor thermal stability, poor water resistance, and poor gloss, and achieve no effect on color and good hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of quaternary ammonium salt chitosan and organosilicon compound modified cationic water-based polyurethane color fixing agent, comprises the following steps:

[0028] Add 20.0 g of polyoxypropylene diol (N220) into the reaction vessel, mix and stir, heat at a constant temperature in an oil bath at 90°C, vacuumize and dehydrate for 1 h, the vacuum degree is 0.098MPa, cool down to 80°C, and add 11.1 g of IPDI , 1.94 g of hydroxypropyltrimethylammonium chloride chitosan and 0.15 g of di-n-butyltin dilaurate, and 1.2 g of nitrogen-methyl glycol amine (diluted with acetone to a mass fraction of 35%) was added dropwise until the system The prepolymer was obtained when the NCO value basically reached the theoretical value. The theoretical R value was 1.56. Then the temperature was lowered to 60°C, and 1.55 g of 3-aminopropyltrimethoxysilane (KH540) was added. After the end-capping reaction was complete, the theoretical R The value is 1.20. Cool th...

Embodiment 2

[0033] A kind of preparation method of quaternary ammonium salt chitosan and organosilicon compound modified cationic water-based polyurethane color fixing agent, comprises the following steps:

[0034]Add 20.0 g of polyoxypropylene diol (N220) into the reaction vessel, mix and stir, heat at a constant temperature in an oil bath at 90°C, and vacuum dehydrate for 1 h with a vacuum degree of 0.098 MPa. Cool down to 80°C, add 11.1 g IPDI, 1.29 g carboxymethylhydroxypropyltrimethylammonium chloride chitosan and 0.15 g di-n-butyltin dilaurate, drop 1.2 g nitrogen-methyl glycol amine (with Diluted with acetone to 35% by mass), until the NCO value in the system basically reached the theoretical value, the prepolymer was obtained, and the theoretical R value was 1.78, then the temperature was lowered to 60°C, and γ-aminopropyltriethoxysilane ( KH550) 1.89 g, with a complete capping reaction and a theoretical R value of 1.20. Cool the oil bath to 40°C, dilute with acetone (about 3-5 g...

Embodiment 3

[0039] A kind of preparation method of quaternary ammonium salt chitosan and organosilicon compound modified cationic water-based polyurethane color fixing agent, comprises the following steps:

[0040] Add 20.0 g of polyoxypropylene diol (N220) into the reaction vessel, mix and stir, heat at a constant temperature in an oil bath at 90°C, and vacuum dehydrate for 1 h with a vacuum degree of 0.098 MPa. Cool down to 80°C, add 11.1 g IPDI, 0.81 g hydroxypropyltrimethylammonium chloride chitosan and 0.15 g di-n-butyltin dilaurate, dropwise add 1.2 g nitrogen-methyl glycol amine (diluted with acetone to The mass fraction is 35%), until the NCO value in the system basically reaches the theoretical value, the prepolymer is obtained, the theoretical R value is 2.00, then the temperature is lowered to 60°C, and N-β-(aminoethyl)-γ-aminopropyl is added 2.15 g of methyldimethoxysilane (KH602), with a complete capping reaction, and a theoretical R value of 1.20. Cool the oil bath to 40°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com