Drying apparatus of textile printing machine

A drying device and printing machine technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of low thermal efficiency and heat energy loss, and achieve the effects of protecting the environment, high thermal efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention are described with reference to the above drawings.

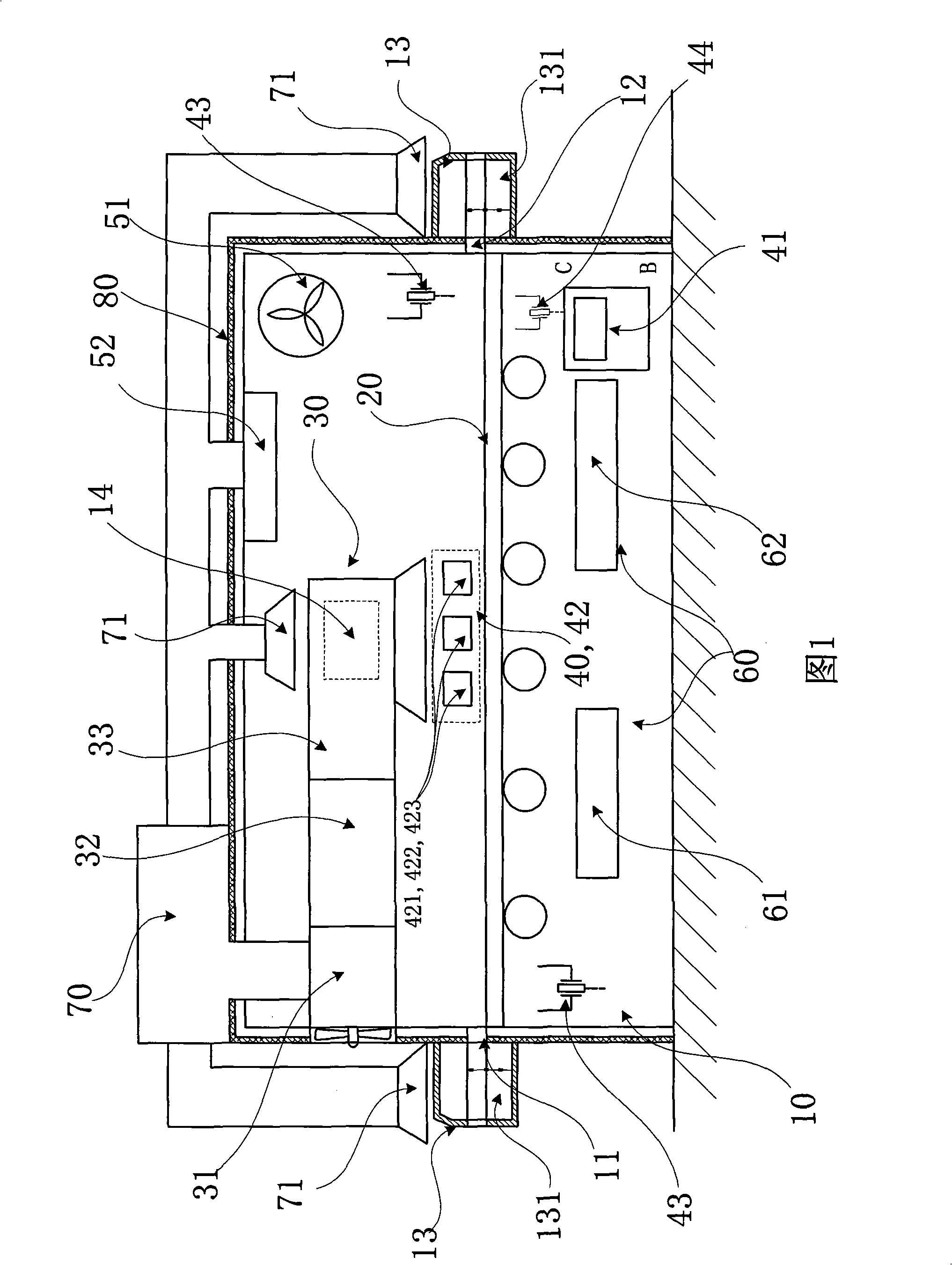

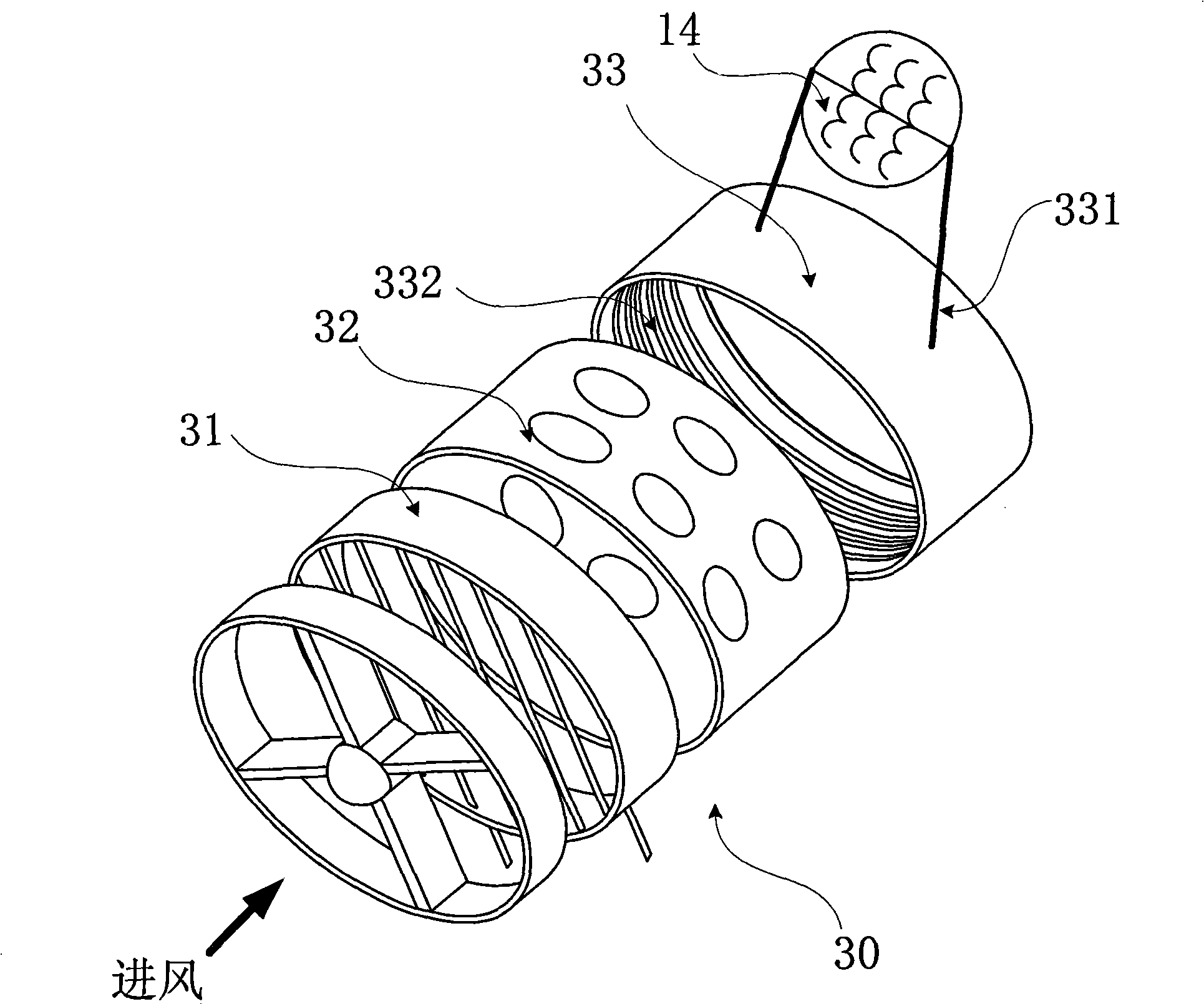

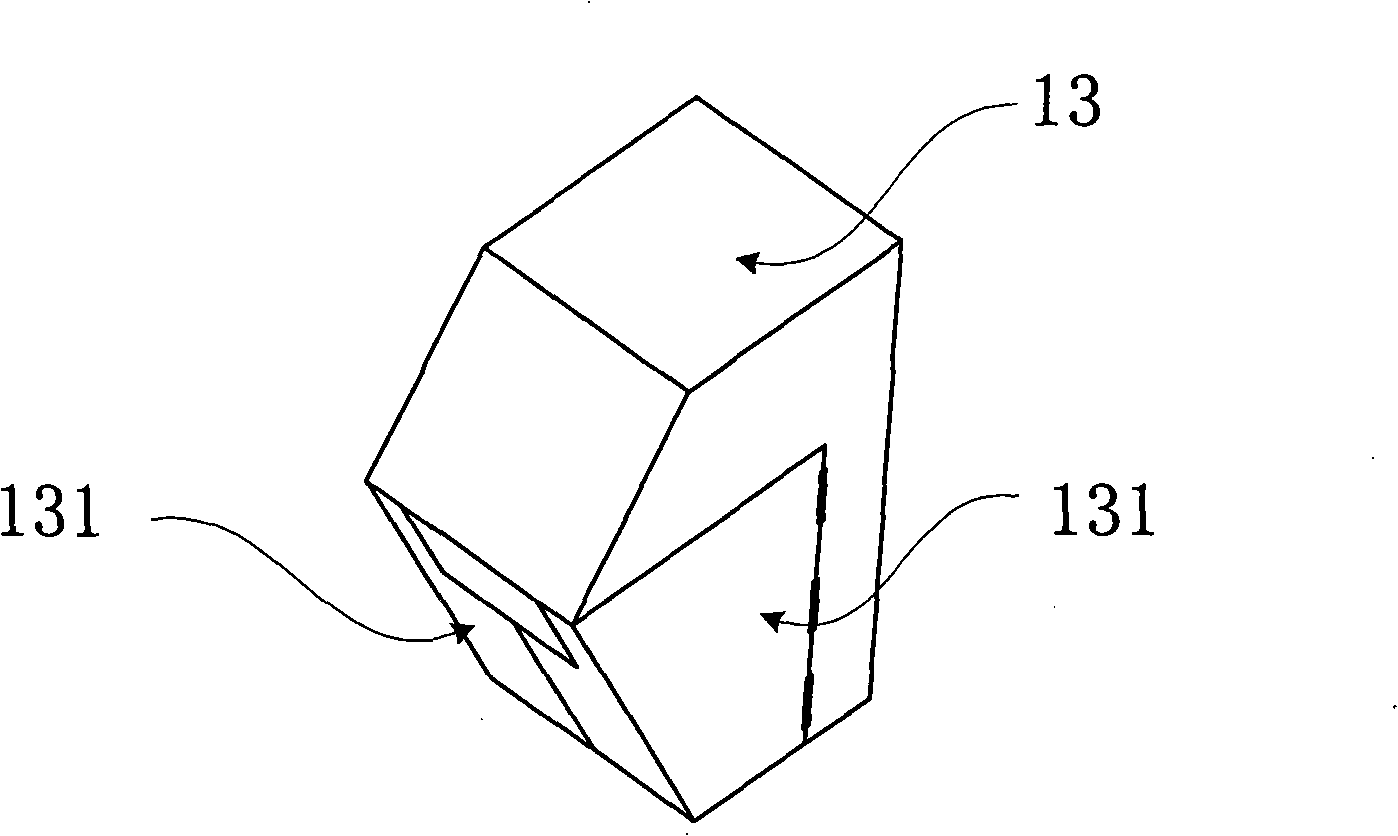

[0017] From Figure 1 and figure 2 It can be seen from the figure that the drying device of this textile printing machine includes a drying box 10 with material inlet and outlet 11-12 at both ends, a material transmission device 20 is placed in the drying box 10, and is connected to the material inlet 11 and the material outlet 12, the main heating device 30 is placed in the drying box 10; the main heating device 30 includes at least three different types of heating units 31-33, and the drying device also includes a control system 40 and The air supply system 50 , the control system 40 controls the main heating device 30 and the air supply system 50 , the control system 40 includes a controller 41 and a temperature relay group 42 . In the present invention, the control system 40 is used to control the heating program of each heating unit, and different heating units are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com