Preparation method of tungsten disulfide nanotube

A tungsten disulfide and nanotube technology, applied in chemical instruments and methods, nanotechnology, tungsten compounds, etc., to achieve the effects of low temperature, simple and easy-to-control production process, and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A porous alumina template with a pore diameter of about 100 nm and uniform size was prepared by a secondary anodic oxidation method. Dissolve 0.35 g of ammonium tetrathiotungstate in 5 mL of dimethyl sulfoxide, and magnetically stir to prepare a 0.2 mol / L precursor solution. The prepared AAO template was immersed in the precursor solution for 30 min, and then the AAO template was placed in an oven at 70°C to fully volatilize the dimethyl sulfoxide solvent. This process was repeated three times. Put the AAO template loaded with the precursor into a horizontal tubular heating furnace, and feed H at a flow rate of 50 mL / min. 2 / N 2 Mixed gas (H 2 and N 2 The volume ratio is 1:9), and at the same time, heat the tube furnace to 550°C at a heating rate of 10°C / min, keep it warm for 1-2h to fully react, and then cool to room temperature with the furnace to obtain blue-black tungsten disulfide nanotube.

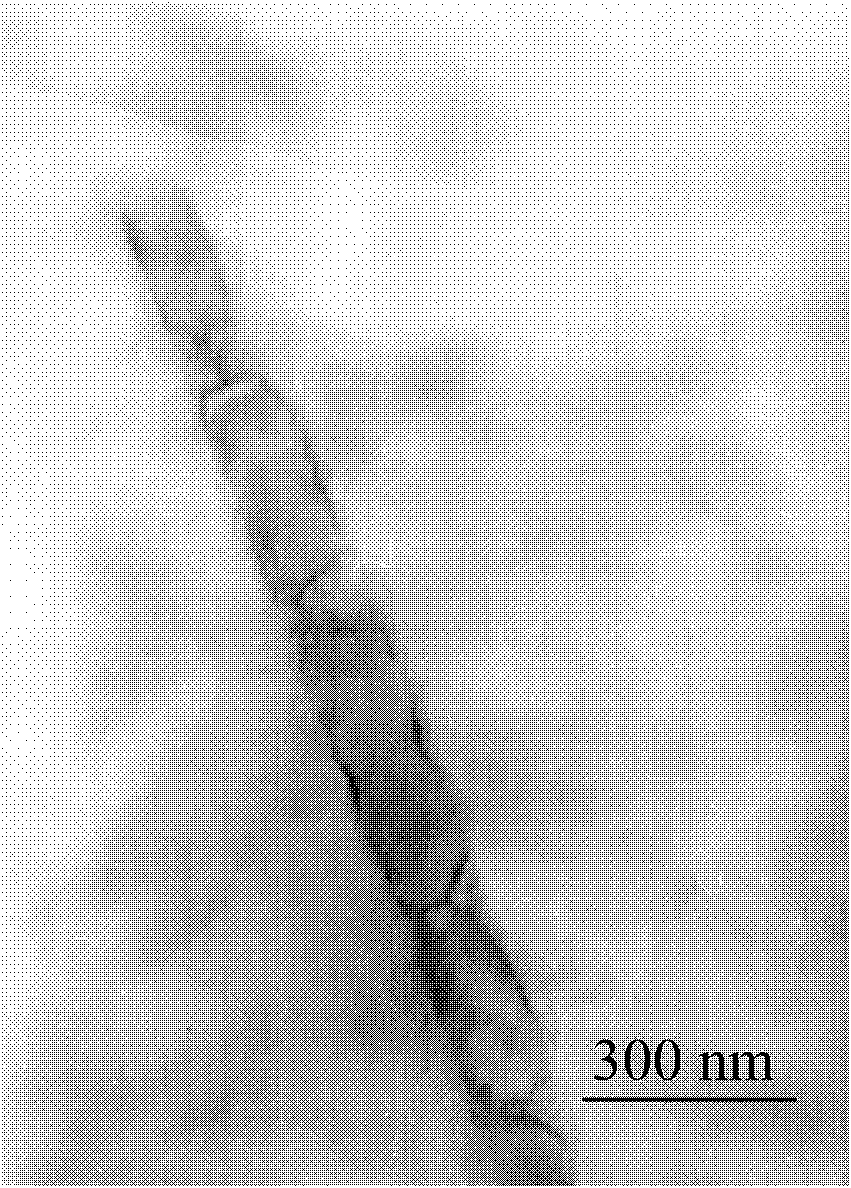

[0021] figure 1 It is a transmission electron microscope (TEM) phot...

Embodiment 2

[0023] A porous alumina template with a pore diameter of about 100 nm and uniform size was prepared by a secondary anodic oxidation method. Dissolve 0.35 g of ammonium tetrathiotungstate in 5 mL of dimethyl sulfoxide, and magnetically stir to prepare a 0.2 mol / L precursor solution. The precursor solution was introduced into the AAO template by suction filtration, and then the AAO template was placed in an oven at 70°C to fully volatilize the dimethyl sulfoxide solvent. Put the AAO template loaded with the precursor into a horizontal tubular heating furnace, and feed H at a flow rate of 50 mL / min. 2 / N 2 Mixed gas (H 2 and N 2 The volume ratio is 1:9), while heating the tube furnace to 550°C at a heating rate of 10°C / min, keeping it warm for 1-2h to fully react, and then cooling to room temperature with the furnace to obtain tungsten disulfide nanotubes.

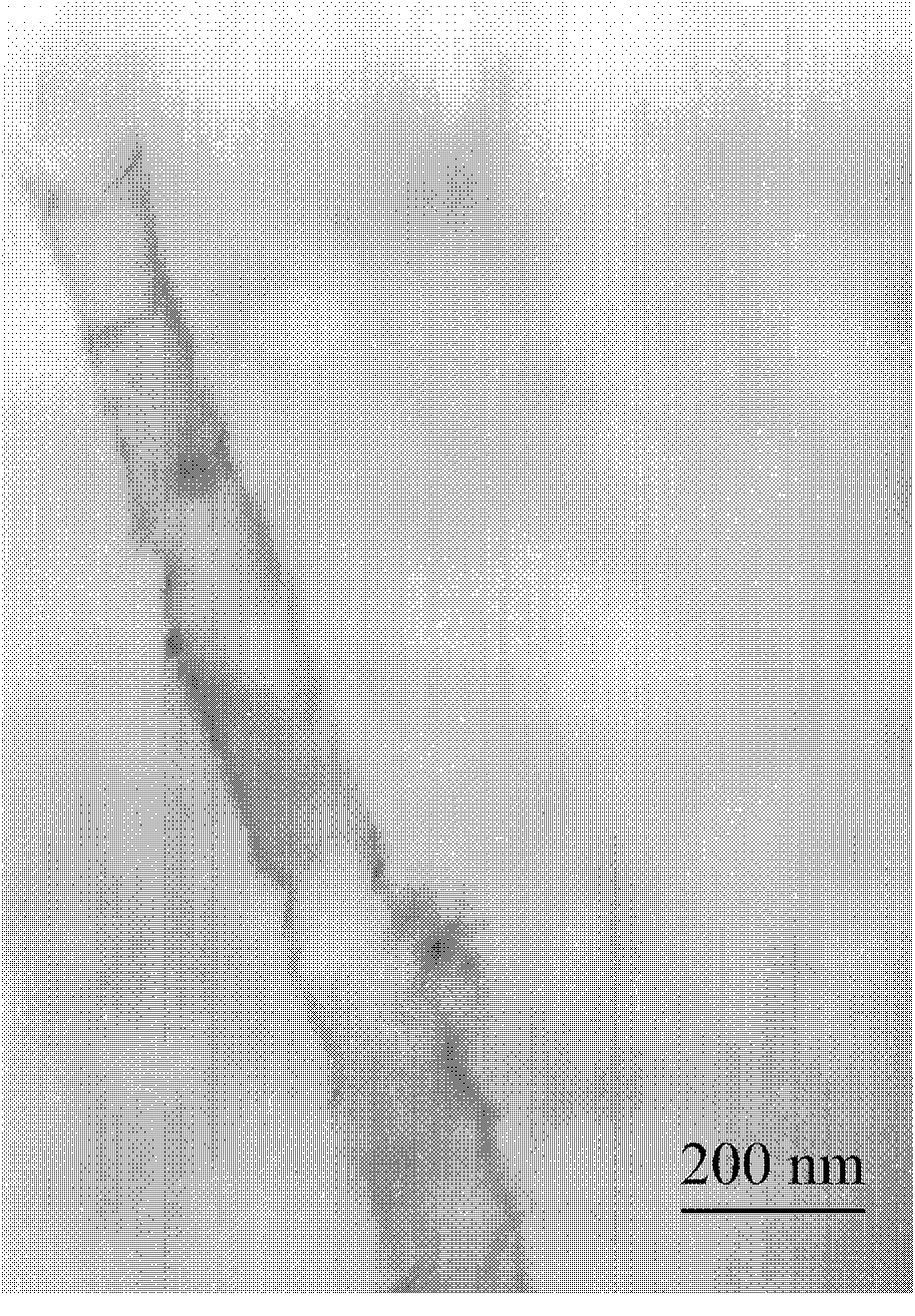

[0024] figure 2 It is a transmission (TEM) photo of the tungsten disulfide nanotubes prepared in this embodiment. It...

Embodiment 3

[0026] A porous alumina template with a pore diameter of about 100 nm and uniform size was prepared by a secondary anodic oxidation method. Dissolve 0.54 g of ammonium tetrathiotungstate in 5 mL of dimethyl sulfoxide, and magnetically stir to prepare a 0.3 mol / L precursor solution. The prepared AAO template was immersed in the precursor solution for 2 days, and then the AAO template was placed in an oven at 70° C. to fully volatilize the dimethyl sulfoxide solvent. Put the AAO template soaked in the solution into a horizontal tubular heating furnace, and pass H at a flow rate of 50mL / min. 2 / N 2 Mixed gas (H 2 and N 2 The volume ratio is 1:9), and at the same time, heat the tube furnace to 550°C at a heating rate of 10°C / min, keep it warm for 1-2h to fully react, and then cool to room temperature with the furnace to obtain blue-black tungsten disulfide nanotube.

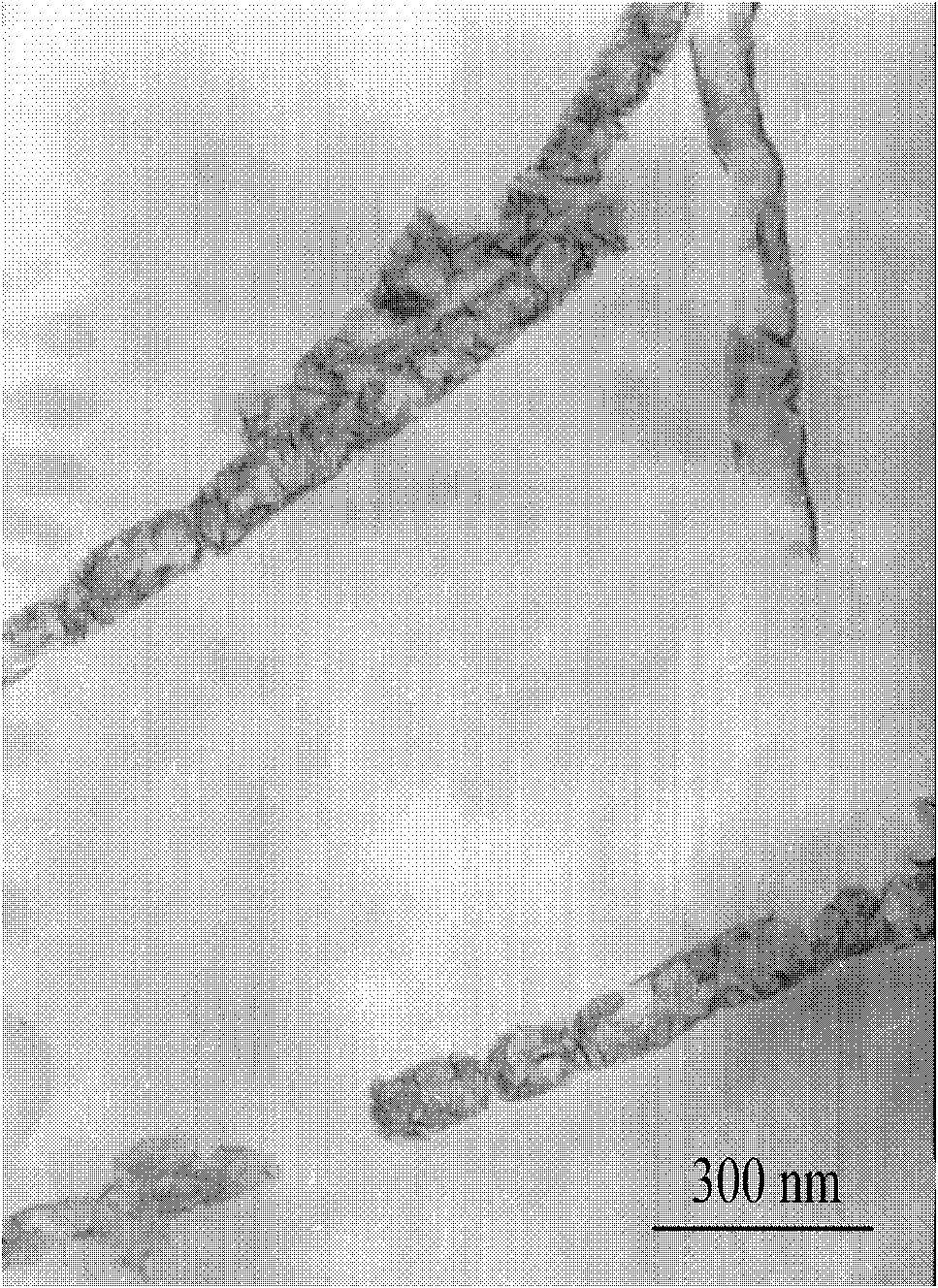

[0027] image 3 It is a transmission (TEM) photo of the tungsten disulfide nanotubes prepared in this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com