Preparation method of g-C3N4-TiO2 mesoporous composite visible light catalyst

A technology of g-c3n4-tio2 and 1.g-c3n4-tio2, which is applied in the field of preparation of g-C3N4-TiO2 mesoporous composite visible light photocatalysts, can solve the problem of unfavorable visible light catalytic activity, reduce energy level matching, improve etc. problem, to achieve the effect of simple and easy-to-control production process, low cost and high photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, put 10g of urea in a quartz crucible, heat it in a tube furnace at 450°C for 2h under an air atmosphere, and heat up at a rate of 10°C / min to obtain a yellow powder called g-C 3 N 4 Nanosheets;

[0024] Step 2, 0.05g of g-C obtained in step 1 3 N 4 Disperse the nanosheets in 60mL acetic acid, ultrasonically disperse for 0.5h, then add 1.6mL tetrabutyl titanate, stir, ultrasonically disperse for 0.5h, transfer the solution into a stainless steel reaction kettle, seal it, and place it in a vacuum drying oven at 120°C for 24h , cooled to room temperature to obtain the reaction product;

[0025] Step 3, the reaction product obtained in step 2 is separated, washed repeatedly with deionized water and absolute ethanol, dried at 60°C under vacuum for 10 hours, and finally annealed in a tube furnace at 500°C for 2 hours to obtain a white product powder , which is g-C 3 N 4 -TiO 2 Mesoporous composite visible light photocatalyst.

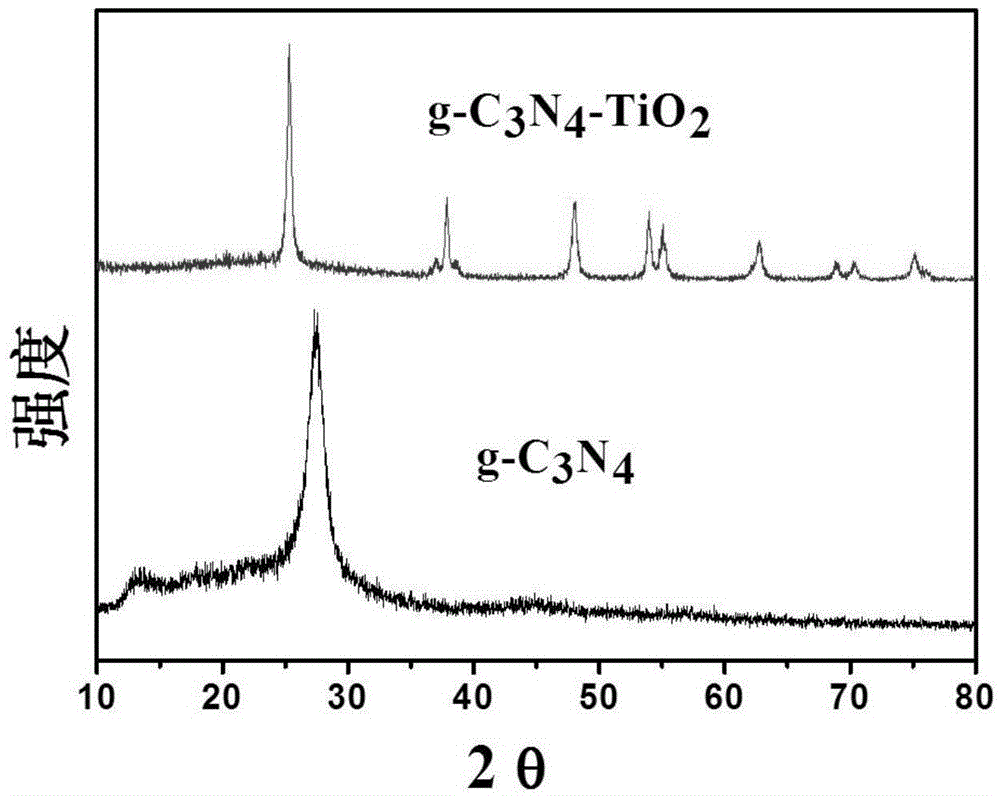

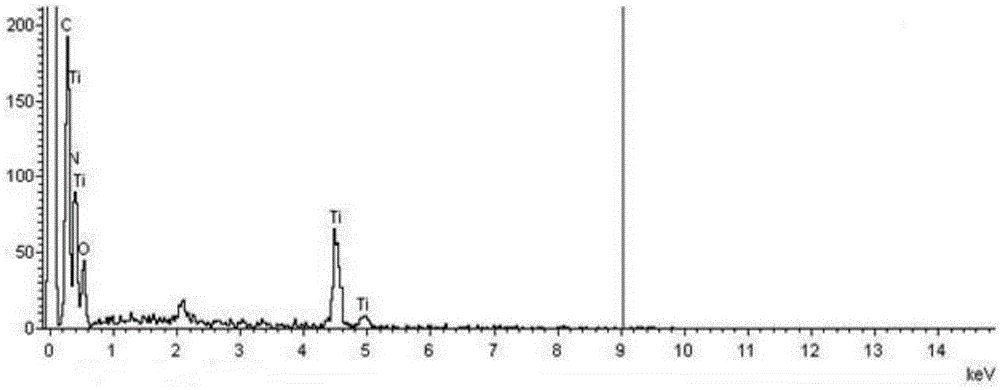

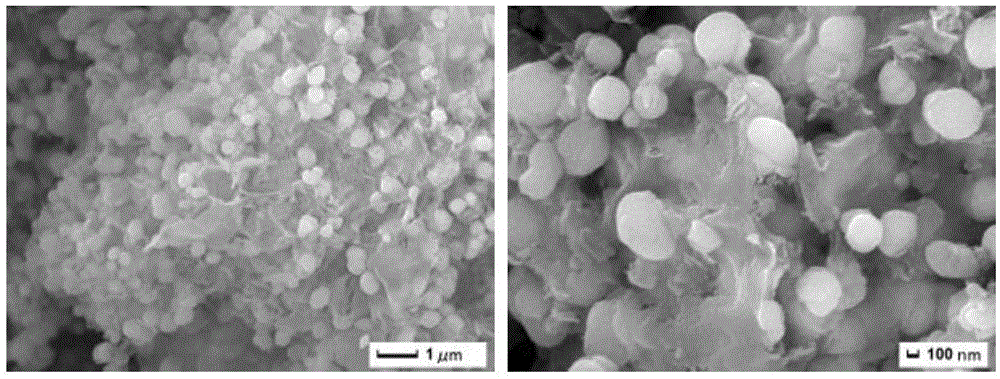

[0026] figure 1 for g-C 3 N 4...

Embodiment 2

[0031] Step 1, put 10g of urea in a quartz crucible, heat it in a tube furnace at 450°C for 2h under an air atmosphere, and heat up at a rate of 10°C / min to obtain a yellow powder called g-C 3 N 4 Nanosheets;

[0032] Step 2, 0.20g of g-C obtained in step 1 3 N 4 Disperse the nanosheets in 60mL acetic acid, ultrasonically disperse for 0.5h, then add 1.6mL tetrabutyl titanate, stir, ultrasonically disperse for 0.5h, transfer the solution into a stainless steel reactor, seal it, and place it in a vacuum oven at 200°C for 24h , cooled to room temperature to obtain the reaction product;

[0033] Step 3: Separate the reaction product obtained in step 2, wash it repeatedly with deionized water and absolute ethanol, dry it under vacuum at 80°C for 10 hours, and finally anneal it in a tube furnace at 450°C for 2 hours to obtain a white product powder , which is g-C 3 N 4 -TiO 2 Mesoporous composite visible light photocatalyst.

[0034]The resulting g-C 3 N 4 -TiO 2 Mesoporo...

Embodiment 3

[0036] Step 1, put 10g of urea in a quartz crucible, heat it in a tube furnace at 450°C for 2h under an air atmosphere, and heat up at a rate of 10°C / min to obtain a yellow powder called g-C 3 N 4 Nanosheets;

[0037] Step 2, 0.1g of g-C obtained in step 1 3 N 4 Disperse the nanosheets in 60mL acetic acid, ultrasonically disperse for 0.5h, then add 1.6mL tetrabutyl titanate, stir, ultrasonically disperse for 0.5h, transfer the solution into a stainless steel reaction kettle, seal it, and place it in a vacuum drying oven at 180°C for 24h , cooled to room temperature to obtain the reaction product;

[0038] Step 3, the reaction product obtained in step 2 is separated, washed repeatedly with deionized water and absolute ethanol, dried at 60°C under vacuum for 10 hours, and finally annealed in a tube furnace at 550°C for 2 hours to obtain a white product powder , which is g-C 3 N 4 -TiO 2 Mesoporous composite visible light photocatalyst.

[0039] The resulting g-C 3 N 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com