Nitrogen and sulfur-codoped graphene quantum dot and preparation method thereof

A graphene quantum dot, nitrogen-sulfur technology, applied in the field of graphene, can solve the problems of limiting the wide application of nitrogen-sulfur co-doped graphene quantum dots, difficulty in obtaining raw materials, troublesome and time-consuming operation, etc., and achieves excellent photocatalytic effect, excellent Optical performance, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

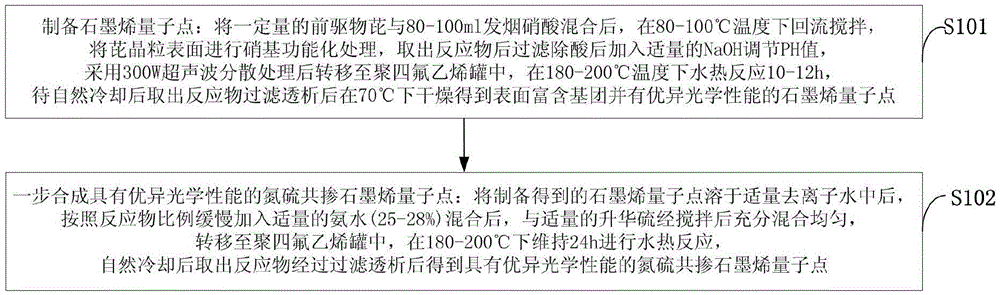

[0036] Such as figure 1 As shown, the preparation method of the nitrogen-sulfur co-doped graphene quantum dots of the embodiment of the present invention comprises the following steps:

[0037] S101: Preparation of graphene quantum dots: mix a certain amount of precursor pyrene with 80-100ml of fuming nitric acid, reflux and stir at a temperature of 80-100°C, perform nitro functional treatment on the surface of pyrene grains, and take out the reactants After filtering and removing acid, add an appropriate amount of NaOH to adjust the pH value, use 300W ultrasonic dispersion treatment, transfer it to a polytetrafluoroethylene tank, and conduct a hydrothermal reaction at a temperature of 180-200°C for 10-12h, and take out the reactant after natural cooling for filtration and dialysis After drying at 70°C, graphene quantum dots with rich groups on the surface and excellent optical properties are obtained.

[0038] S102: One-step synthesis of nitrogen-sulfur co-doped graphene qua...

Embodiment 1

[0041] 1) Weigh 1g of pyrene and 80ml of fuming nitric acid and stir slowly, stir at 80°C for 12h, and take out after natural cooling;

[0042]2) Take out the reactant prepared in step 1, filter the waste liquid with a 0.22 μm microporous membrane, and wash the filtrate several times with deionized water;

[0043] 3) Add 0.4g NaOH to the reactant prepared in step 2, put it in 300W ultrasonic dispersion for 1h, then immediately put it into a high-temperature reactor, and react at a constant temperature of 180°C for 12h;

[0044] 4) After natural cooling, take out the reactant prepared in step 3, remove solid impurities with a 0.22 μm microporous membrane, and then dialyze with a 3500Da dialysis bag for 48 hours to remove excess ions in the reactant;

[0045] 5) Take out the reactant prepared in step 4, evaporate and dry at 70° C., and finally obtain graphene quantum dots.

Embodiment 2

[0047] 1) Take by weighing 0.1g of graphene quantum dots prepared in Example 1, add 100ml of deionized water, degrade 10min with ultrasonic wave 300W to make graphene quantum dots fully dissolve in deionized water, then slowly add 100ml of ammonia water, under magnetic stirring conditions Slowly add 0.25g of sublimed sulfur according to the ratio of the reactants, and stir for 30min to fully disperse the sublimed sulfur in the mixture;

[0048] 2) Transfer the mixture in step 1 to a polytetrafluoroethylene tank, and maintain a constant temperature hydrothermal reaction at 180°C for 24 hours in a high-temperature reactor;

[0049] 3) After natural cooling, take out the reactant prepared in step 2, remove solid impurities with a 0.22 μm microporous membrane, and then dialyze with a 3500Da dialysis bag for 48 hours to remove excess ions in the reactant;

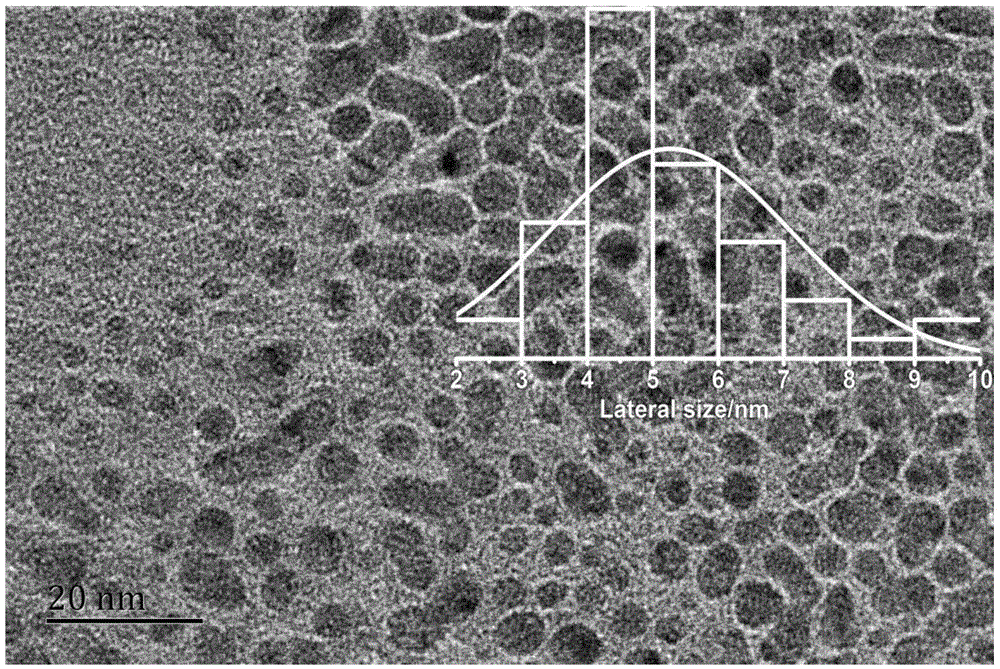

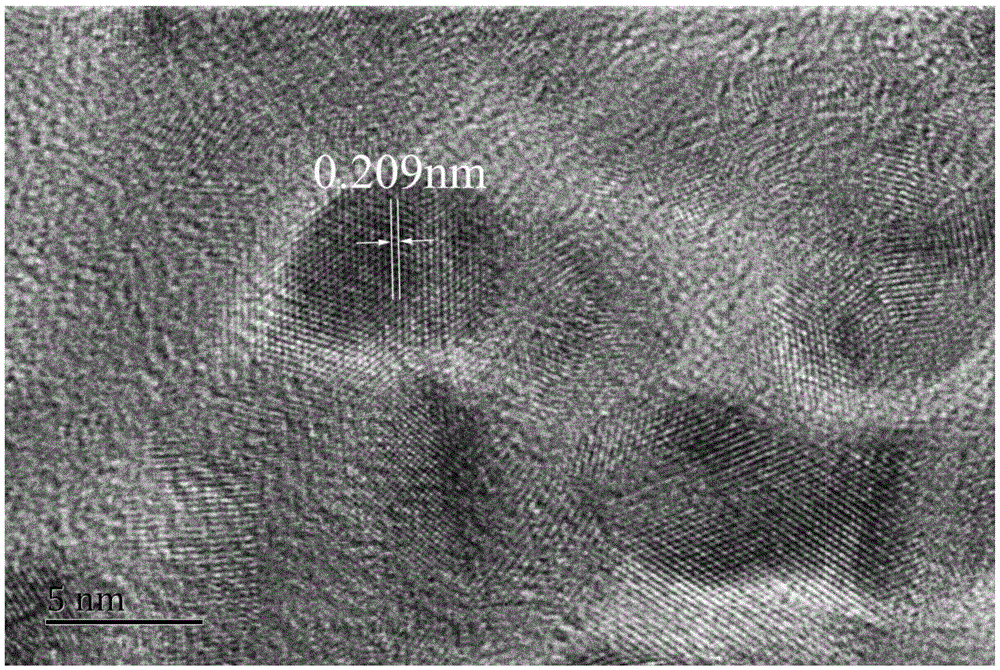

[0050] 4) Take out the reactant prepared in step 3, evaporate and dry at 70° C., and finally obtain nitrogen-sulfur co-doped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com