Controllable discolouring foundation cream/liquid foundation

A liquid foundation and color-changing powder technology, which is applied in the field of cosmetics and its preparation, can solve problems such as difficulty in mastering the production process, affecting the color-changing speed and effect of products, and defects in color-changing pearl powder, so as to achieve simple and controllable production technology and reliable color-changing effect Controlled and colorful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

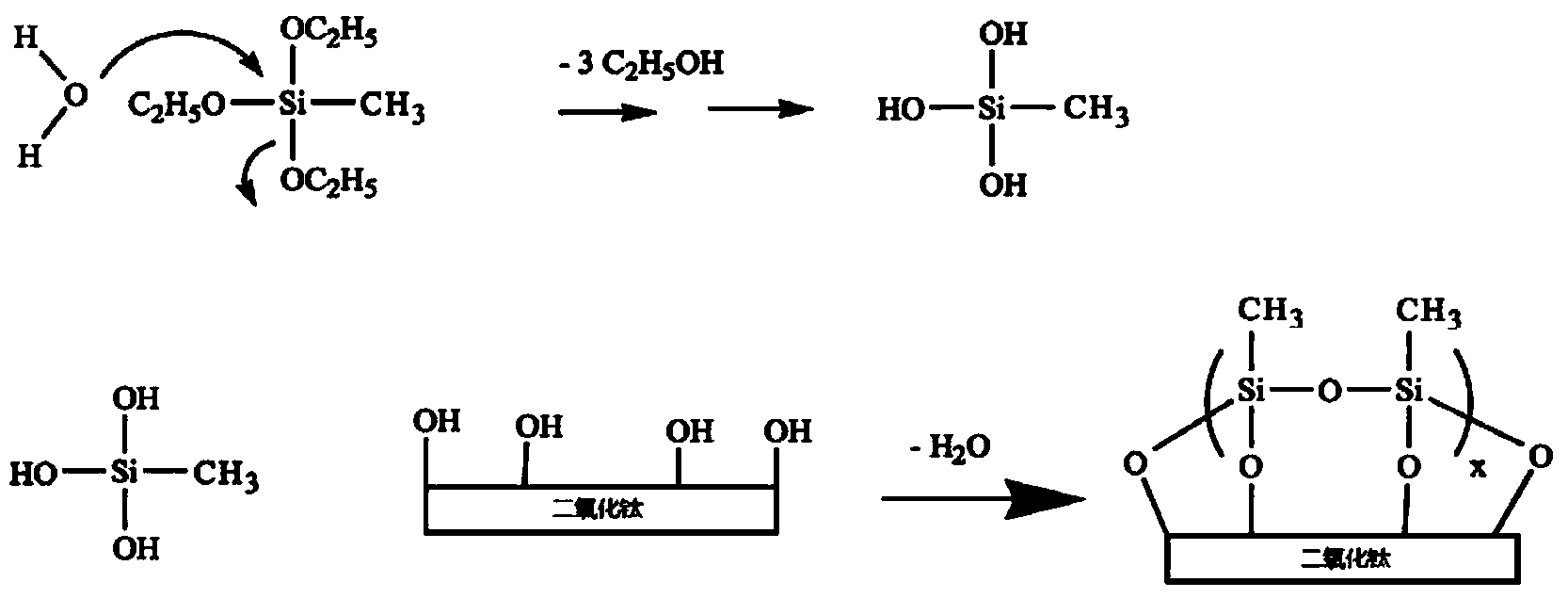

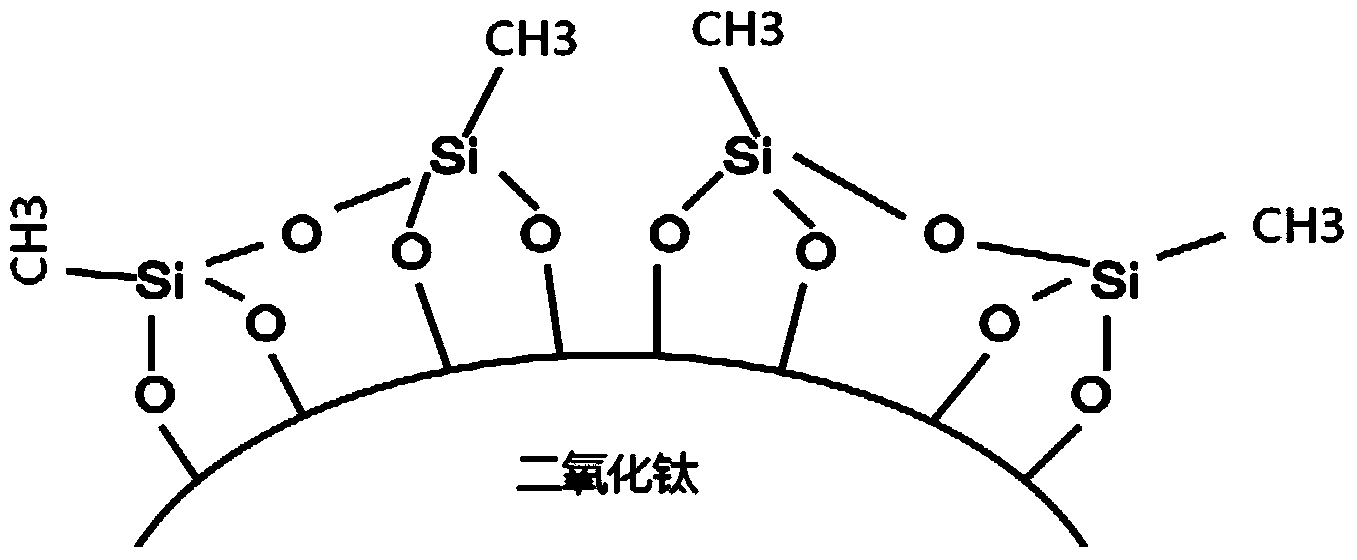

[0089] The process of triethoxymethyl silylation surface treatment of titanium dioxide:

[0090] Mix 0.45kg of triethoxymethylsilane with 1.05kg of 95% ethanol evenly to make a surface treatment solution, ready to use;

[0091] Add 15kg of titanium dioxide into the high-speed mixer, and under high-speed stirring, spray the above prepared surface treatment liquid into the high-speed mixer through the oil spray tank, and stir fully to make the reaction solution and titanium dioxide mix evenly;

[0092] The powder is discharged, immediately sent to the oven, baked at 105°C for 4 hours, and cooled naturally.

[0093] Triethoxyoctyl silylation surface treatment process of inorganic pigments:

[0094] Mix 0.45kg of triethoxyoctylsilane with 1.05kg of 95% ethanol evenly to make a surface treatment solution, ready to use;

[0095] Add 15kg of inorganic pigments into the high-speed mixer, and under high-speed stirring, spray the above prepared surface treatment liquid into the high-s...

Embodiment 2

[0097] Embodiment 2: Several color-changing powder premixes with different proportions: the following proportions are all mass percentages,

[0098]

[0099] The adjustment of the above ratio is only reflected in the color of the foundation product, which can be freely allocated according to the color of the foundation product required. Foundation products are the basis of makeup, and the content of titanium dioxide is usually between 75% and 95%. If it is too high, it will be too white, and if it is too low, the color will be too heavy, which is not conducive to achieving a good makeup effect.

Embodiment 3

[0100] Example 3: Color Changing Cream Foundation

[0101] Recipe composition:

[0102]

[0103]

[0104] Preparation Process:

[0105] 1. Mix and stir phase A, and homogenize for 1 minute to completely disperse the DC9040 silicone elastomer.

[0106] 2. Heat phase A to 55-60 degrees, add phase B powder, and homogenize for 1 minute to disperse the powder evenly.

[0107] 3. At the same time, heat phase C to about 55-60 degrees to dissolve completely.

[0108] 4. Speed up the stirring speed of phase AB (200-300 rpm), slowly add phase C into phase AB to make the emulsification complete

[0109] 5. Stir and cool down to below 45 degrees, add phase D to make the paste white, and discharge.

[0110] 6. During the cooling process, the stirring speed is (200-300 rpm). Turns white in about 2-3 hours.

[0111] The foundation product of Example 3 of the present invention has an obvious discoloration effect during use, fast discoloration, strong hiding power, easy to apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com