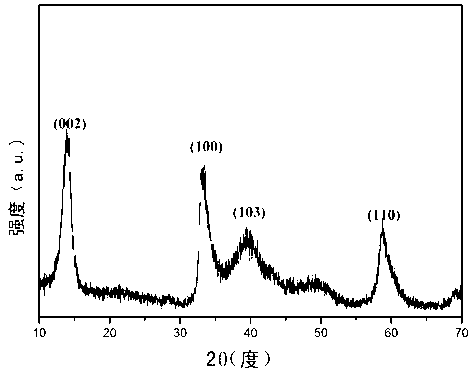

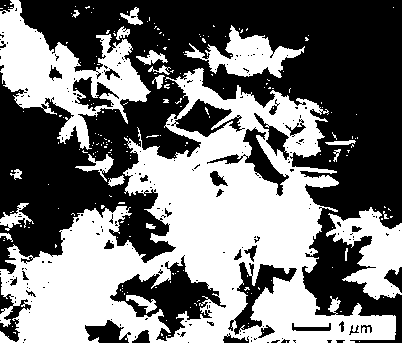

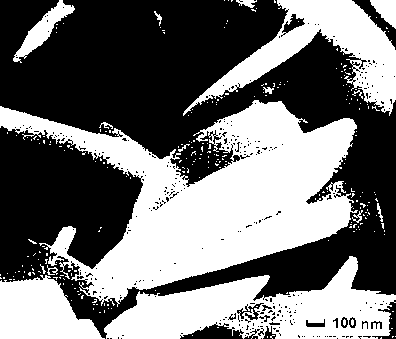

Method for preparing hexagonal molybdenum disulfide nanosheet as anti-friction additive

A technology of hexagonal molybdenum disulfide and anti-friction additives, applied in the direction of molybdenum sulfide, nanotechnology for materials and surface science, nanotechnology, etc., to achieve simple and easy-to-control production process, broad development prospects, and improve anti-friction and anti-wear capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (a) Add 0.2 ml of ammonia solution (25wt%) into 16 ml of absolute ethanol and 40 ml of distilled water mixed solution, then add 0.13 g of F127, 0.4 g of resorcinol and 0.56 ml of formaldehyde solution, put the solution in Stir in a constant temperature heating magnetic stirrer in a 30°C constant temperature water bath until uniform; then, put the above mixed solution in a stainless steel reaction kettle, a hydrothermal reaction kettle, and place it in a vacuum drying oven at 180°C for 24h, then cool to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol respectively, and finally dried at 60° C. for 10 h under vacuum conditions to obtain resorcinol-formaldehyde resin nanopolymer balls.

[0029] (b) Add 0.88g Na 2 MO 4 , 1.40g Na 2 S, 0.7g NH 2 Dissolve OH·HCl in 70 ml of distilled water, then add 0.3 g of resorcinol-formaldehyde resin nano-polymeric balls prepared before, stir...

Embodiment 2

[0033] 0.88g Na 2 MO 4 , 1.40g Na 2 S, 0.7gNH 2 OH·HCl was dissolved in 70 ml of distilled water, then 0.3 g of the carbon nanospheres prepared in (a) of Example 1 were added, and the pH value was adjusted to about 7 with 2 mol / L hydrochloric acid. After stirring for 30min, the mixture was transferred to a 100ml stainless steel reaction kettle, placed in a vacuum oven at 180°C for 24h, and cooled to room temperature. After centrifugation, the reaction product was washed repeatedly with deionized water and absolute ethanol, dried at 80°C for 10 hours under vacuum, and then annealed at 450°C for 2 hours in a tube furnace to obtain a black powder, namely hexagonal molybdenum disulfide Nanosheets.

[0034] The prepared hexagonal molybdenum disulfide nanosheets were added to the heavy-duty gear oil CKD220, and oleic acid was used as the surface dispersant of nanomaterials, and the prepared oil samples were dispersed at a constant temperature of 60°C with an ultrasonic disperser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com