Preparation method of LaZSM-5 molecular sieve, its application and using method

A technology of molecular sieve and reaction kettle, which is applied in the field of preparation of LaZSM-5 molecular sieve, can solve the problems of insufficient catalyst activity, expensive catalyst cost, and long production cycle, and achieve the effects of easy large-scale promotion, easy control, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

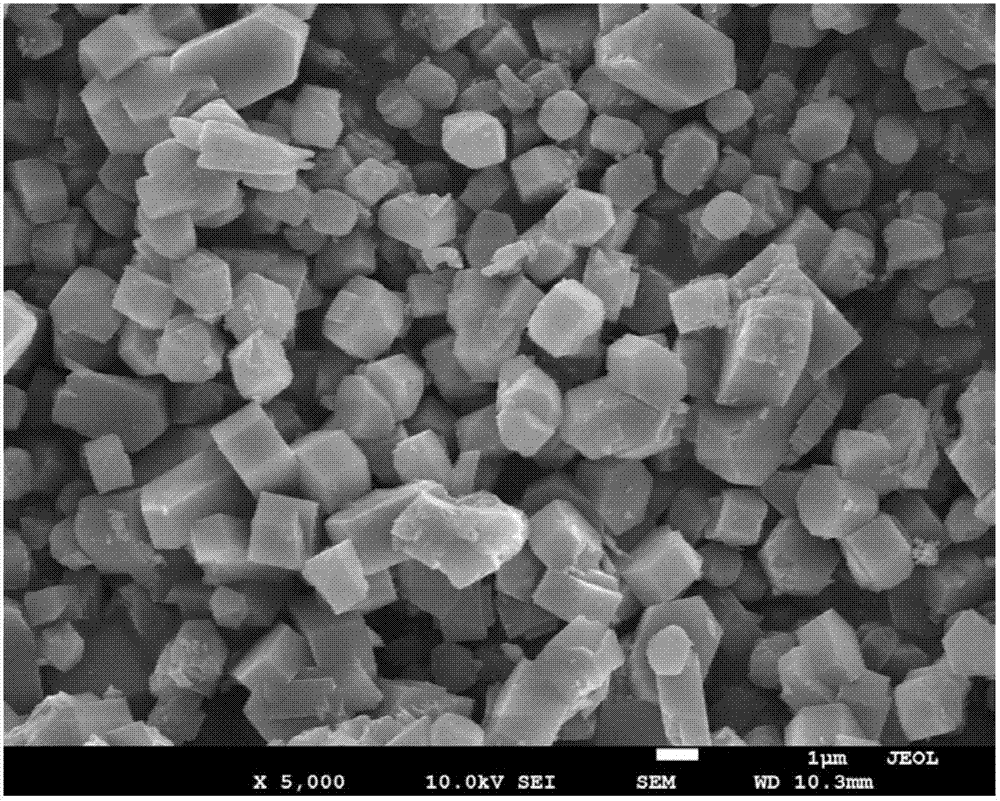

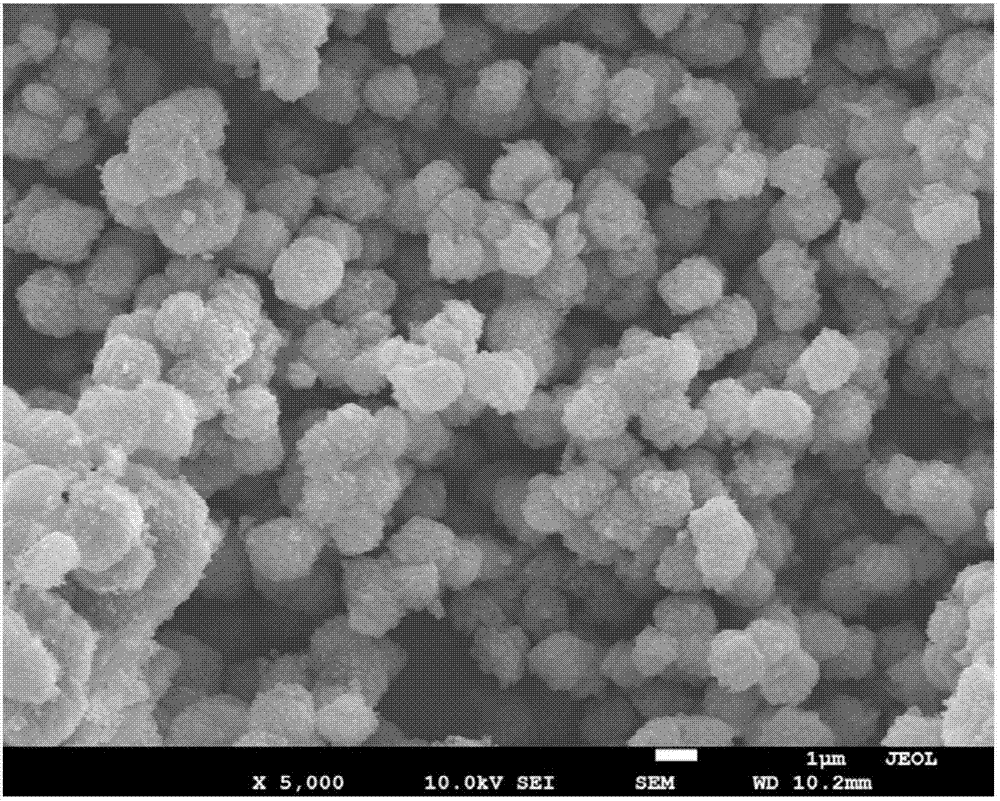

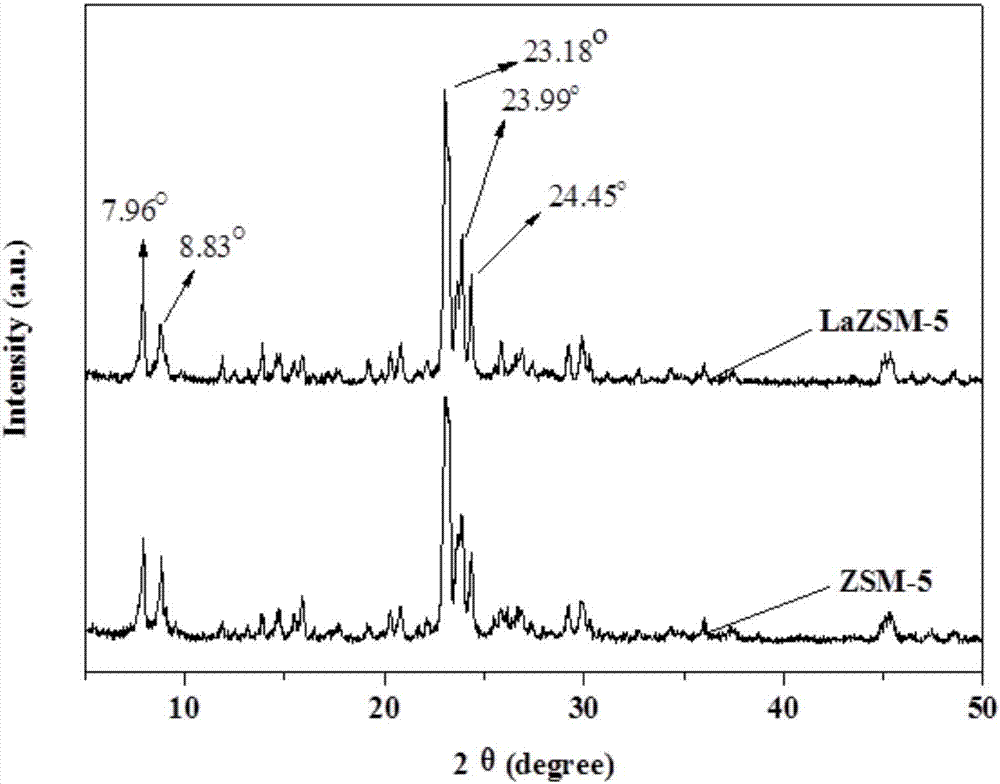

[0031] The preparation method of present embodiment LaZSM-5 molecular sieve, carry out according to the following steps:

[0032] Step 1. At 40°C, add 100mL of deionized water and 30mL of 40% tetrapropylammonium hydroxide solution to the beaker, transfer to a constant temperature magnetic stirrer and stir for 30min, then add 25mL of ethyl orthosilicate, 0.4g Aluminum sulfate, 0.3g sodium hydroxide and 0.6g lanthanum carbonate were stirred for 3 hours at 28°C to obtain a reaction mixture;

[0033] Step 2. Transfer the reaction mixture to a stainless steel reactor (lined with polytetrafluoroethylene) under airtight conditions, and crystallize at 180°C for 48 hours to obtain a crystallized product;

[0034] Step 3, cooling the crystallized product to room temperature with water, washing with deionized water for 3 times, transferring the washed crystallized product to a drying oven, and drying at 110°C for 20 hours to obtain a white powder;

[0035] Step 4: Transfer the white pow...

Embodiment 2

[0037] The preparation method of present embodiment LaZSM-5 molecular sieve, carry out according to the following steps:

[0038] Step 1. At 20°C, add 120mL deionized water and 15mL n-butylamine to the beaker, transfer to a constant temperature magnetic stirrer and stir for 30min, then add 40mL fuming silica gel, 0.25g sodium metaaluminate, and 0.6g sodium hydroxide and 0.25g of lanthanum nitrate, stirred at 20°C for 3h to obtain a reaction mixture;

[0039] Step 2. Transfer the reaction mixture to a stainless steel reactor (lined with polytetrafluoroethylene) under airtight conditions, and crystallize at 185°C for 28 hours to obtain a crystallized product;

[0040] Step 3: cooling the crystallized product to room temperature, washing with deionized water for 4 times, transferring the washed crystallized product to a drying oven, and drying at 115°C for 16 hours to obtain a white powder;

[0041] Step 4: Transfer the white powder to a muffle furnace and calcinate at 560° C. f...

Embodiment 3

[0043] The preparation method of present embodiment LaZSM-5 molecular sieve, carry out according to the following steps:

[0044] Step 1. At 35°C, add 200mL deionized water and 45mL ethylenediamine to the beaker, transfer to a constant temperature magnetic stirrer and stir for 30min, then add 35mL tetraethyl orthosilicate, 0.65g pseudoboehmite, 0.45g Sodium hydroxide and 0.2 g of lanthanum chloride were stirred for 3 h at 34 ° C to obtain a reaction mixture;

[0045] Step 2. Transfer the reaction mixture to a stainless steel reactor (lined with polytetrafluoroethylene) under airtight conditions, and crystallize at 195°C for 24 hours to obtain a crystallized product;

[0046] Step 3, cooling the crystallized product to room temperature, washing with deionized water three times, transferring the washed crystallized product to a drying oven, and drying at 120°C for 22 hours to obtain a white powder;

[0047] Step 4: Transfer the white powder to a muffle furnace and calcinate at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com