Electric heating type inside and outside spraying equipment and process for steel-plastic composite pipe

A technology of steel-plastic composite pipe and spraying equipment, which is applied in the direction of coating, device for coating liquid on the surface, pretreatment surface, etc., to achieve the effect of continuous production process, uniform thickness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

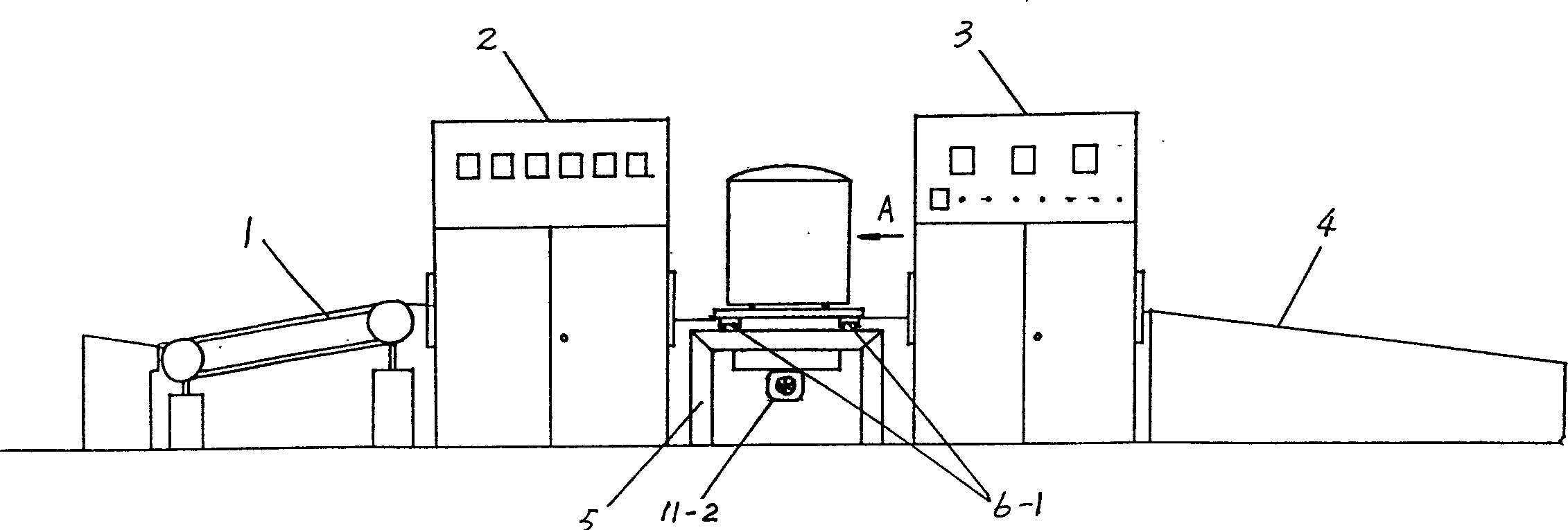

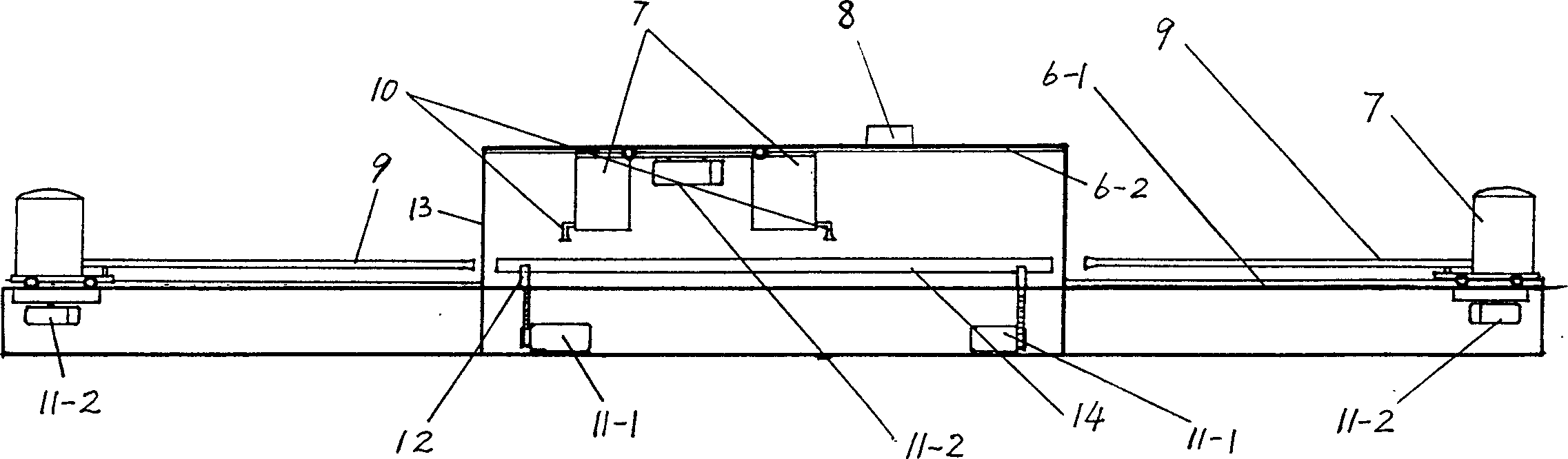

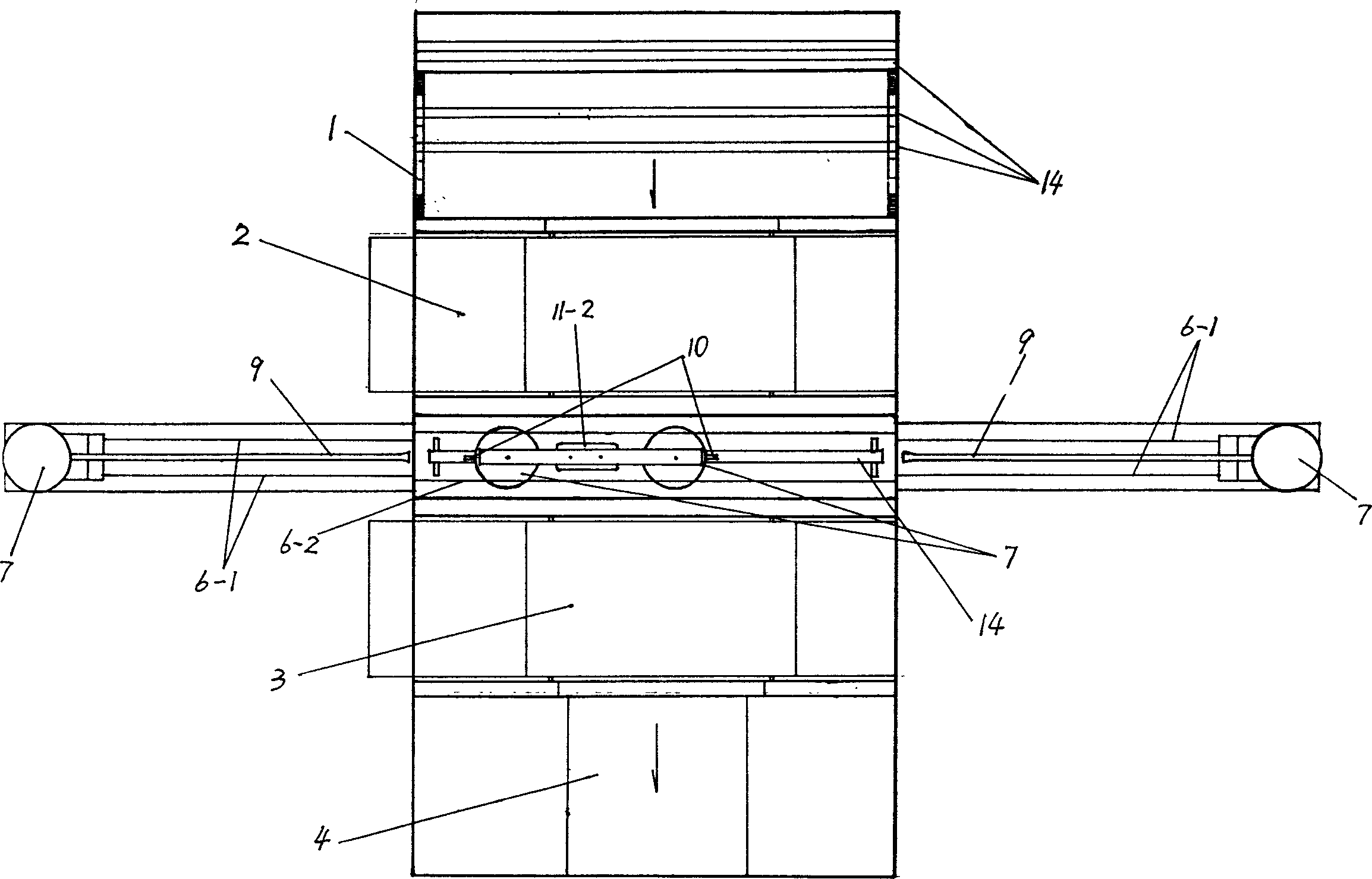

[0017] As shown in the figure, this embodiment consists of a feeding device 1, an electric heating box 2, a leveling and curing box 3, a cooling frame 4, a workbench 5, a lower rail 6-1, an upper rail 6-2, a fluidization cylinder 7, an electrostatic Generator 8, inner nozzle 9, outer nozzle 10, rotating motor 11-1, moving motor 11-2, runner 12, support 13 and steel pipe 14 form.

[0018] In this example, an internal and external plastic spraying device is provided between the electric heating box 2 and the leveling and curing box 3. The device has a fixed workbench 5. On the longitudinal axis of the workbench, a pair of runners 12 are used to support the steel pipe 14. The steel pipe is driven to rotate by the friction of the runner. A rotating motor 11-1 providing power is installed below the runner. Two slide rails 6-1 are respectively arranged on the workbench on both sides of the extension line of the steel pipe axis. There is a fluidization cylinder 7 that can move along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com