Preparation method of 1,1'-bis (tert-butylphosphine) ferrocene palladium chloride

A technology of tert-butylphosphine and di-tert-butylphosphine, which is applied in the field of preparation of 1,1'-ferrocenepalladium chloride, can solve the problems of unfavorable environment and safety, low catalyst quality, long reaction time, etc. , to achieve broad market prospects and benefits, low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

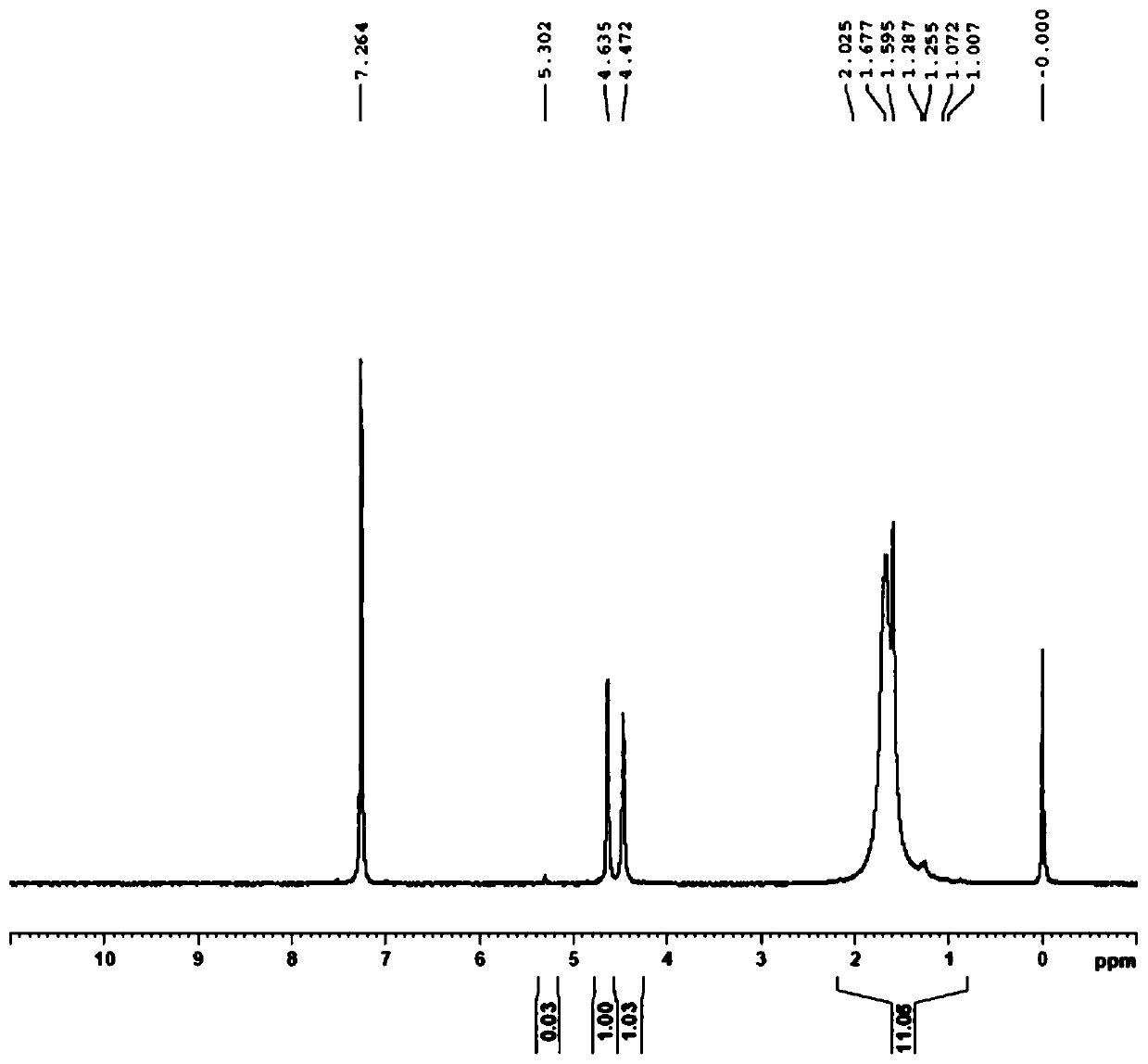

[0032] Dissolve palladium and palladium chloride in 20% dilute hydrochloric acid, pass the resulting palladium solution through a D301 anion exchange resin column (Langfang Kaiou), exchange the chloropalladate group on the resin, and 1,1'-bis( Di-tert-butylphosphine) ferrocene (DtBPF) ethanol solution flows through the resin to obtain a red suspension; the suspension is left to stand and then filtered, and the resin is washed with ethanol to separate the resin and the precipitate. Obtain 1,1'-bis(tert-butylphosphino)ferrocene palladium chloride, the productive rate is 82%, the palladium content is 15.48%, the elemental analysis carbon content: 46.74%, nuclear magnetic H-NMR sees attached figure 1 .

Embodiment 2

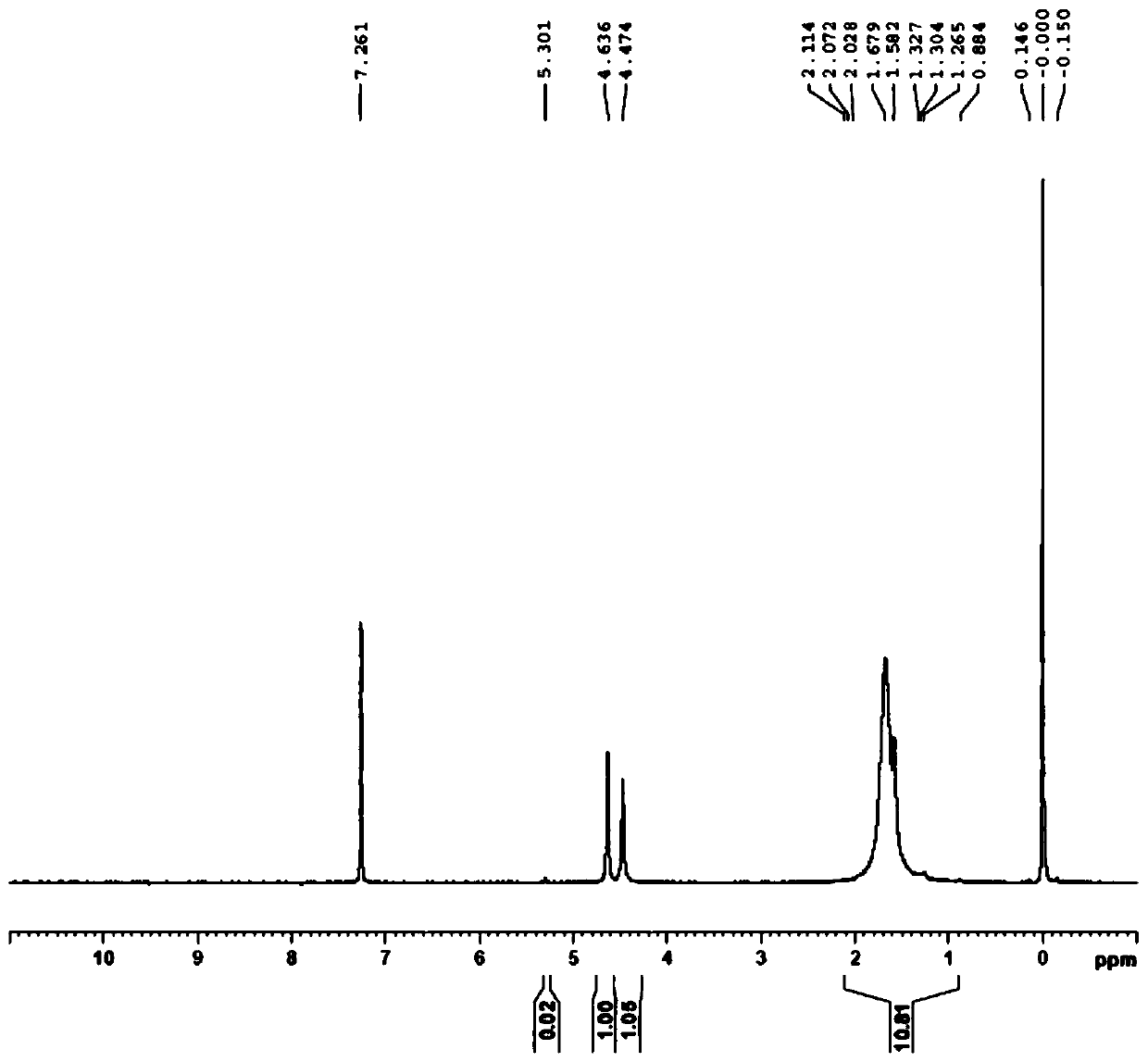

[0034] Dissolve palladium and palladium chloride in 20% dilute hydrochloric acid, pass the resulting palladium solution through a D301 anion exchange resin column (Langfang Kaiou), exchange the chloropalladate group on the resin, and 1,1'-bis( Di-tert-butylphosphine) ferrocene (DtBPF) solution, the solvent is ethanol and n-hexane, flow through the resin to obtain a red suspension; filter the suspension after standing, and use ethanol to wash the resin to separate the resin and precipitate. Obtain 1,1'-di(tert-butylphosphino)ferrocene palladium chloride, the yield is 87%, the palladium content is 15.38%, the elemental analysis carbon content: 48.09%, nuclear magnetic H-NMR sees attached figure 2 .

Embodiment 3

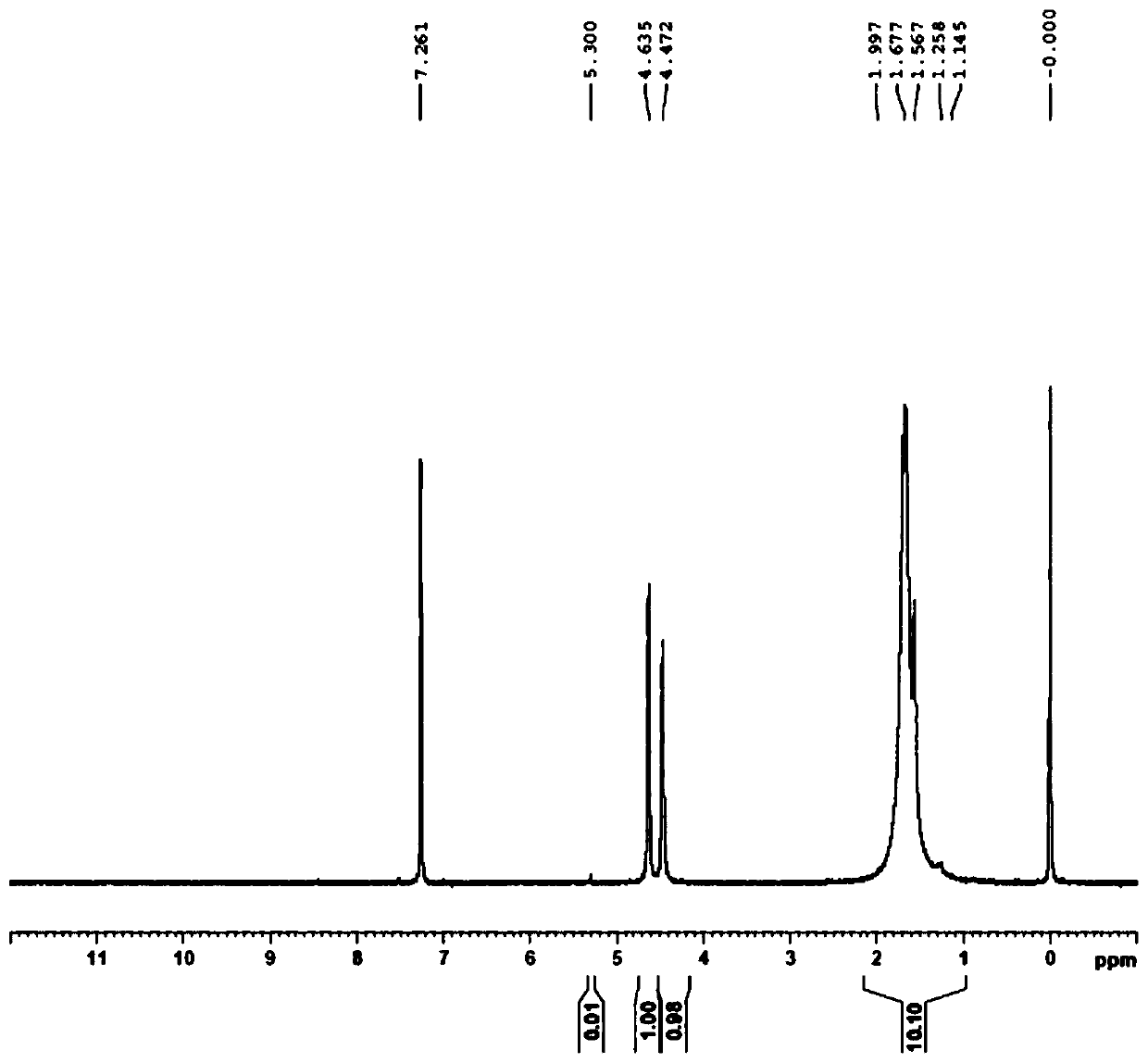

[0036] Dissolve palladium and palladium chloride in 18% dilute hydrochloric acid, pass the resulting palladium solution through a D301 anion exchange resin column (Langfang Kaiou), exchange the chloropalladate group on the resin, and 1,1'-bis( Di-tert-butylphosphine) ferrocene (DtBPF) tetrahydrofuran ethanol solution flows through the resin to obtain a red suspension; the suspension is left to stand and then filtered, and the resin is washed with ethanol to separate the resin and precipitate. Obtain 1,1'-bis(tert-butylphosphino)ferrocene palladium chloride, the yield is 91%, the palladium content is 15.37%, the elemental analysis carbon content: 47.84%, nuclear magnetic H-NMR sees attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com