Reclaiming method for inorganic old sand

An inorganic, used sand technology, applied in the field of casting molding materials, can solve the problems of unsatisfactory casting, low sand core yield, poor quality of recycled sand, etc., to achieve clean production process, continuous production process, and better quality of recycled sand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for regenerating inorganic old sand, comprising the following steps:

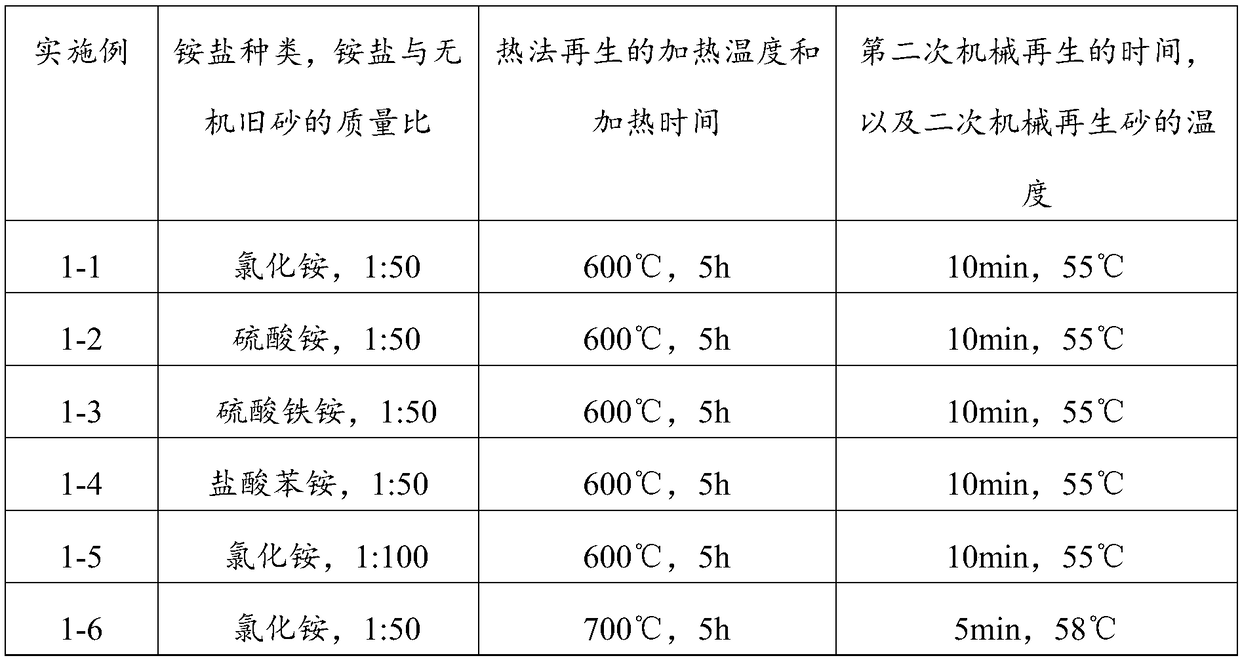

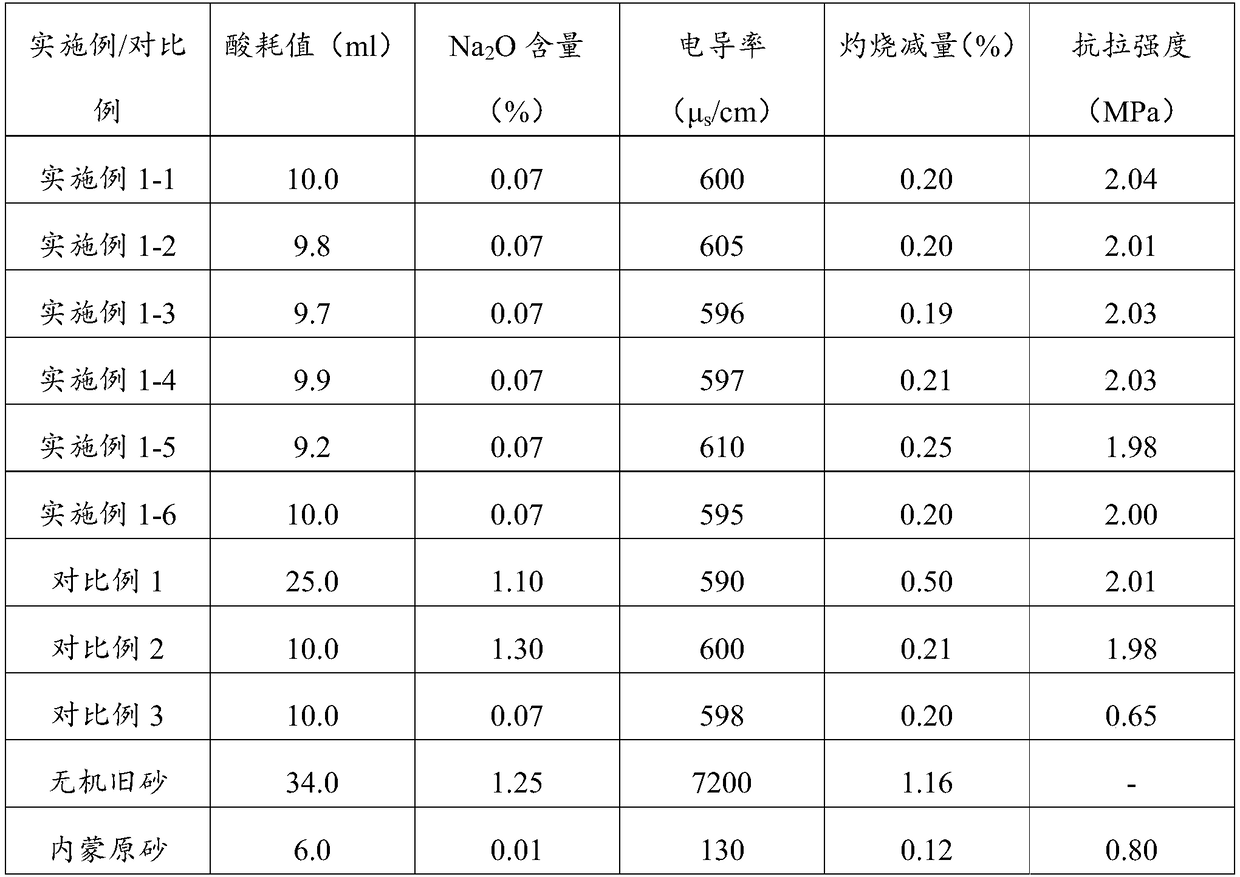

[0044] (1) The first mechanical regeneration: After the ammonium salt is mixed with the old inorganic sand, it is crushed into particles below 6mm by a vibrating crusher. After the crushing is completed, it is sieved to obtain the primary mechanical regeneration sand. The types of ammonium salts and the mass ratio of ammonium salts to inorganic old sand are shown in Table 1.

[0045] (2) Regeneration by thermal method: heat the primary mechanically regenerated sand in a roasting furnace. See Table 1 for the heating temperature and heating time. During the heating process, air is introduced to make the primary mechanical reclaimed sand in a state of boiling heating.

[0046] (3) The second mechanical regeneration: Mechanically grind the thermally regenerated sand in an air-cooled device, while cooling down, and sieve to obtain the secondary mechanically regenerated sand. During this process, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com