Yellowing-resistant antioxidation flame-retardant semi-aromatic polyamide and preparation method thereof

A semi-aromatic polyamide, anti-oxidation technology, applied in the field of semi-aromatic polyamide and its preparation, can solve the problems of anti-oxidation, poor weather resistance, easy yellowing, easy to burn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Preparation and purification of thiadiazole dibenzyl sulfide dicarboxylic acid-4,4'-diaminodicyclohexylmethane salt

[0057] Add 418 kg of thiadiazole dibenzyl sulfide dicarboxylic acid, 210 kg of 4,4'-diaminodicyclohexyl methane, and 200 kg of deionized water into a reactor with mechanical stirring and reflux condenser, and react at 50°C for 0.5 h, control the pH of the solution to 6, to obtain the terephthalic acid-4,4'-diaminodicyclohexylmethane salt reaction solution; centrifuge the above reaction solution while it is hot to remove insolubles, and then transport the reaction solution To the cooling crystallization tank, perform natural cooling and crystallization; filter the precipitated thiadiazole dibenzyl sulfide dicarboxylic acid-4,4'-diaminodicyclohexylmethane salt, collect the filter cake, and rinse with a small amount of water Wash, collect the filtrate as the solvent for the next batch of materials, and dry the filter cake at 60°C under a vacuum of 0.08MPa ...

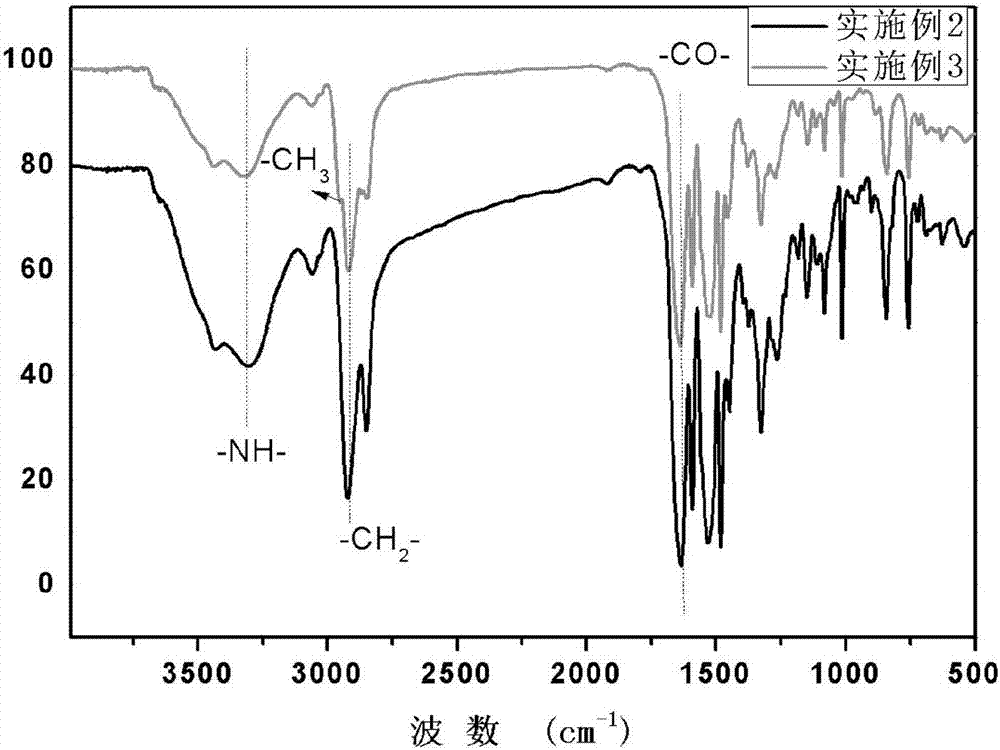

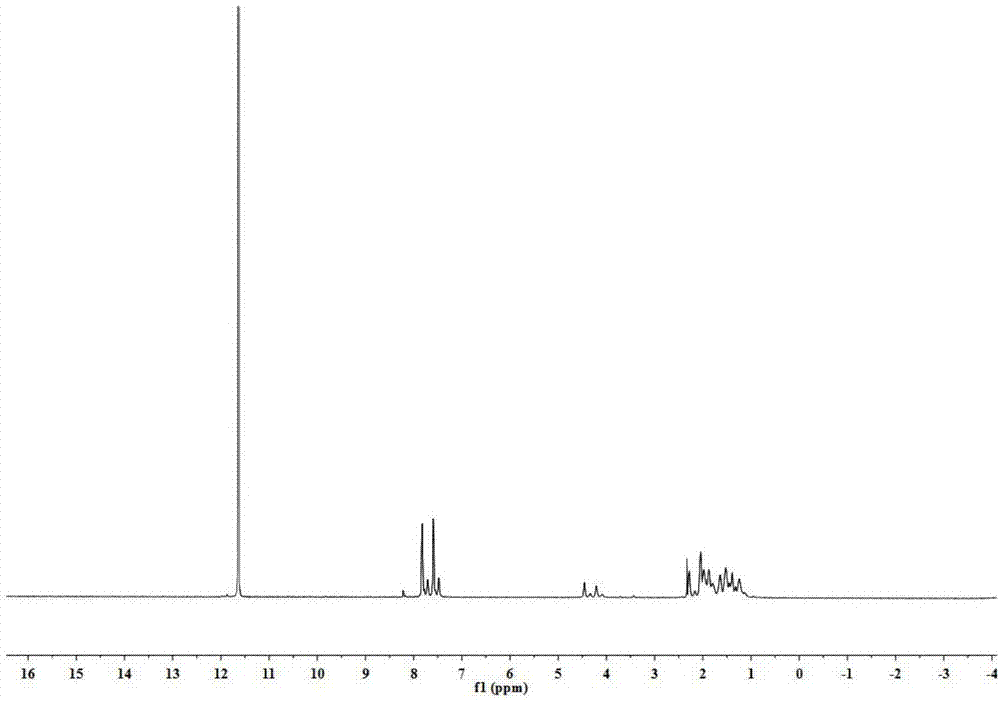

Embodiment 2

[0063] (1) Preparation and purification of 4,4'-diphenylsulfide dicarboxylic acid-4,4'-diaminodicyclohexylmethane salt

[0064] Put 274 kg of 4,4'-diphenyl sulfide dicarboxylic acid, 210 kg of 4,4'-diaminodicyclohexyl methane, and 500 kg of deionized water into a reactor with mechanical stirring and reflux condenser, and react at 100°C 1h, control the pH of the solution to 6.5 to obtain 4,4'-diphenylsulfide dicarboxylic acid-4,4'-diaminodicyclohexylmethane salt reaction solution; centrifuge the above reaction solution while hot to remove Insoluble matter, the reaction liquid is transported to the cooling crystallization tank for natural cooling and crystallization; the precipitated 4,4'-diphenylsulfide dicarboxylic acid-4,4'-diaminodicyclohexylmethane salt is filtered , Collect the filter cake and rinse with a small amount of water. Collect the filtrate as the solvent for the next batch of materials. The filter cake is dried at 80°C under a vacuum of 0.085MPa for 10 hours to obta...

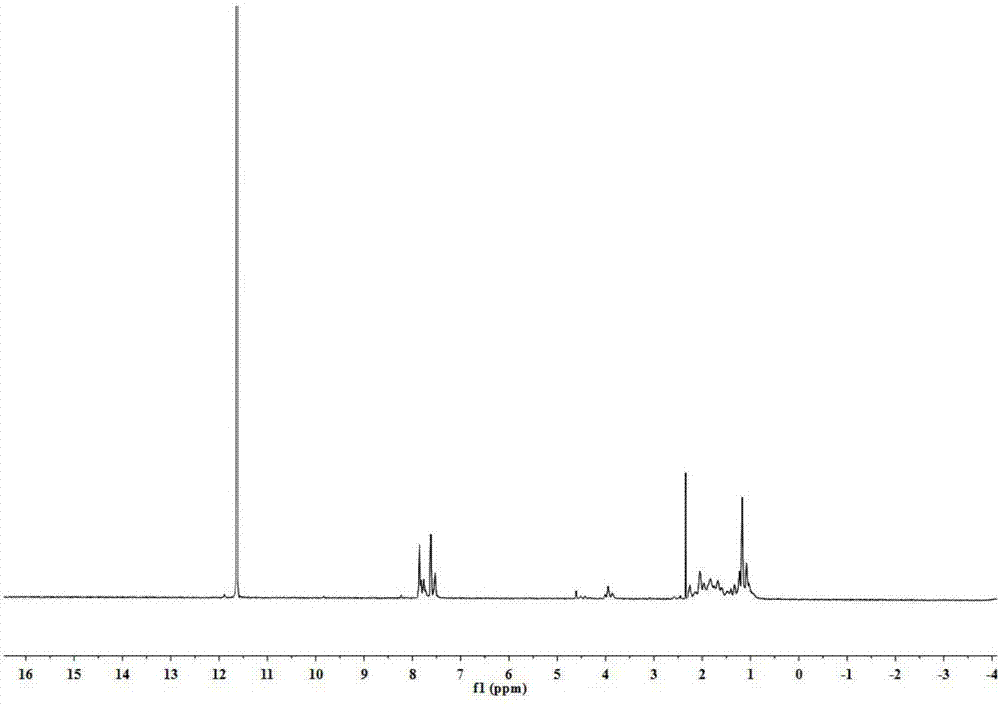

Embodiment 3

[0070] (1) Preparation and purification of 4,4'-diphenylsulfide dicarboxylic acid-3,3'-dimethyl-4,4'-diaminodicyclohexylmethane salt

[0071] Add 274kg of 4,4'-diphenylsulfide dicarboxylic acid, 238kg of 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane, and 2000kg of deionized water into a reflux condenser with mechanical stirring In the reactor, react at 80°C for 3h, and control the pH of the solution to 8 to obtain 4,4'-diphenyl sulfide dicarboxylic acid-3,3'-dimethyl-4,4'-diamino Dicyclohexylmethane salt reaction liquid; the above reaction liquid is centrifuged and filtered while it is hot to remove insoluble materials, and then the reaction liquid is transported to a cooling crystallization tank for natural cooling and crystallization; the precipitated 4,4'-diphenyl sulfide Ether dicarboxylic acid-3,3'-dimethyl-4,4'-diaminodicyclohexylmethane salt was filtered, the filter cake was collected, and rinsed with a small amount of water, and the filtrate was collected as the solvent f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com