Spiral material mixing pneumatic dryer

A kind of air drying and spiral technology, applied in the direction of granular material drying, drying chamber/container, dryer combination, etc., to achieve uniform drying, improve agglomeration phenomenon, and reduce drying temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

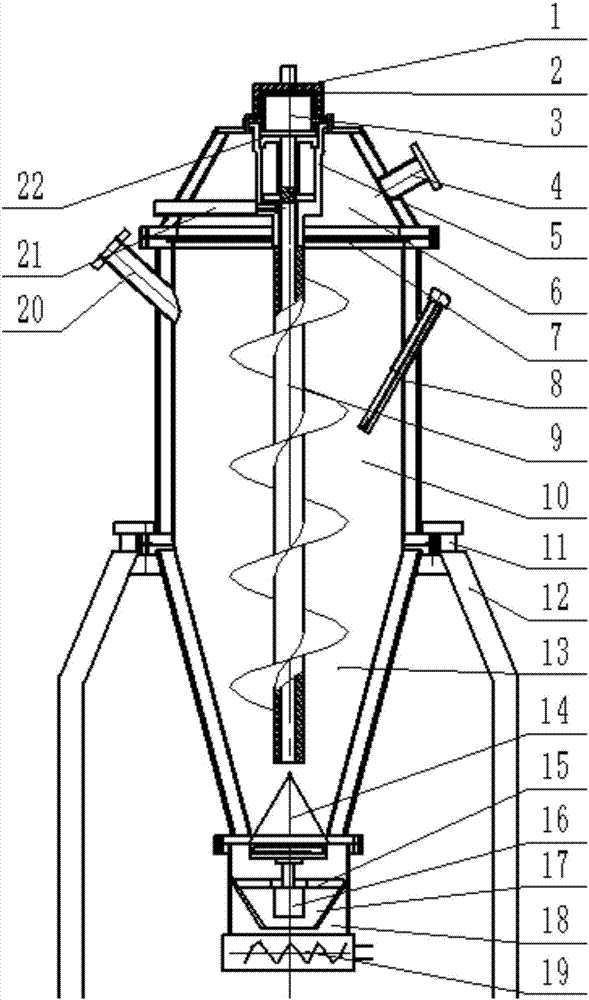

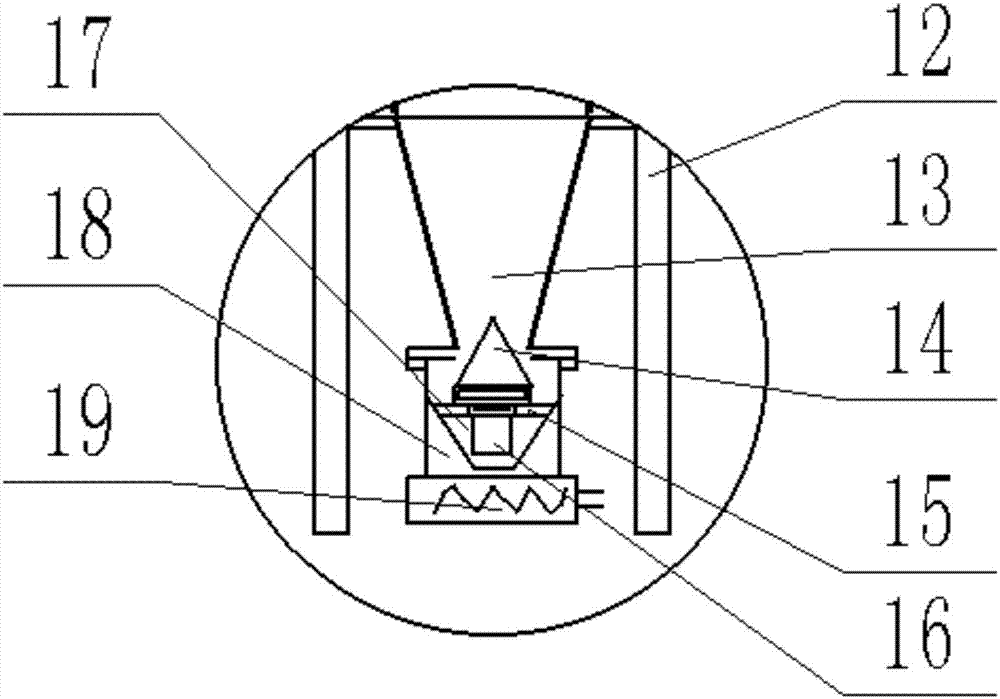

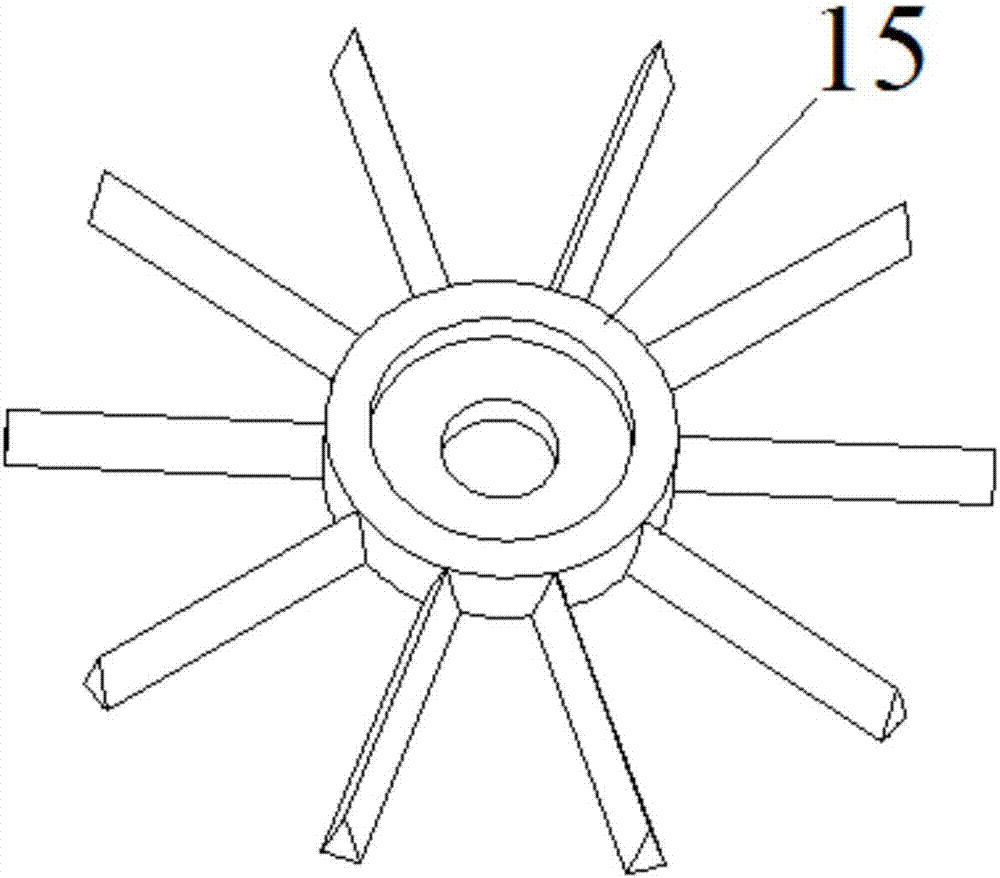

[0023] The invention provides a kind of spiral mixing air dryer (see Figure 1-3 , referred to as dryer), characterized in that the dryer includes a magnetic coupling, vacuum and nitrogen outlet 4, sealing device 5, upper cylinder 6, screen 7, sampling device 8, spiral hollow shaft 9, middle cylinder Body 10, pressure sensor 11, chassis 12, lower cylinder 13, conical blanking plate 14, flower-shaped support plate 15, cylinder 16, unloading cone 17, unloading cylinder 18, screw conveyor 19, feed port 20 , a hot nitrogen gas inlet 21 and an air bearing 22; the magnetic coupling includes a first magnet 1, a separator plate 2 and a second magnet 3;

[0024] The upper cylinder body 6 is connected to the middle cylinder body 10 through a flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com