Formula for preparing polyvinylidene fluoride and carbon nanotube composite film and preparation method of formula

A carbon nanotube composite and polyvinylidene fluoride technology, which is applied in chemical instruments and methods, membrane technology, and semipermeable membrane separation, can solve problems such as strong hydrophobicity, reduced membrane service life, and poor membrane wettability. The preparation process is simple, easy to industrialize, and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

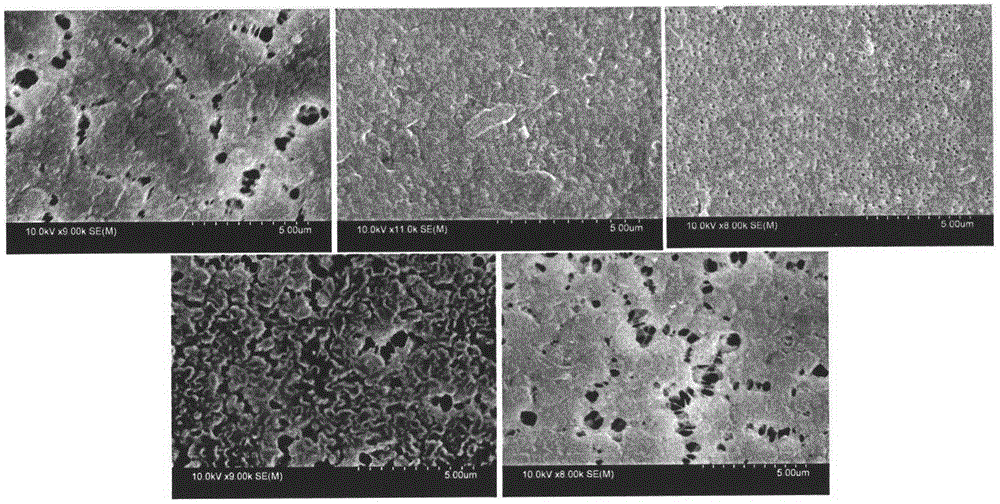

Image

Examples

Embodiment 1

[0026] A preparation method for preparing polyvinylidene fluoride and carbon nanotube flat plate composite film by adopting a blending modification process, the steps of the method are as follows:

[0027] 1) Weigh a certain amount of MWCNTs, use dimethylformamide (DMF) as a solvent, and make the MWCNTs ultrasonic in DMF for 40min, so that the MWCNTs are fully dispersed.

[0028] 2) The polyvinylidene fluoride (PVDF) powder is dried in an oven for a period of time before use to remove moisture.

[0029] 3) Add PVDF powder into the MWCNTs / DMF system to form a casting solution, and vigorously stir in a constant temperature water bath at 70°C for 4 hours to fully dissolve the PVDF powder to obtain a homogeneous solution.

[0030] 4) The obtained casting solution is sealed and stored, and left to stand at room temperature overnight for degassing.

[0031] 5) Scrape the film on a clean glass plate with a 300 μm film scraping rod. After 1 min, immerse the liquid film together with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com