Catalytic ozonation catalyst and preparation method thereof

An ozone catalytic oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the difficulty of catalyst regeneration, incomplete organic matter treatment, and treatment costs. High problems, to achieve the effect of shortening the reaction residence time, the removal effect is remarkable, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

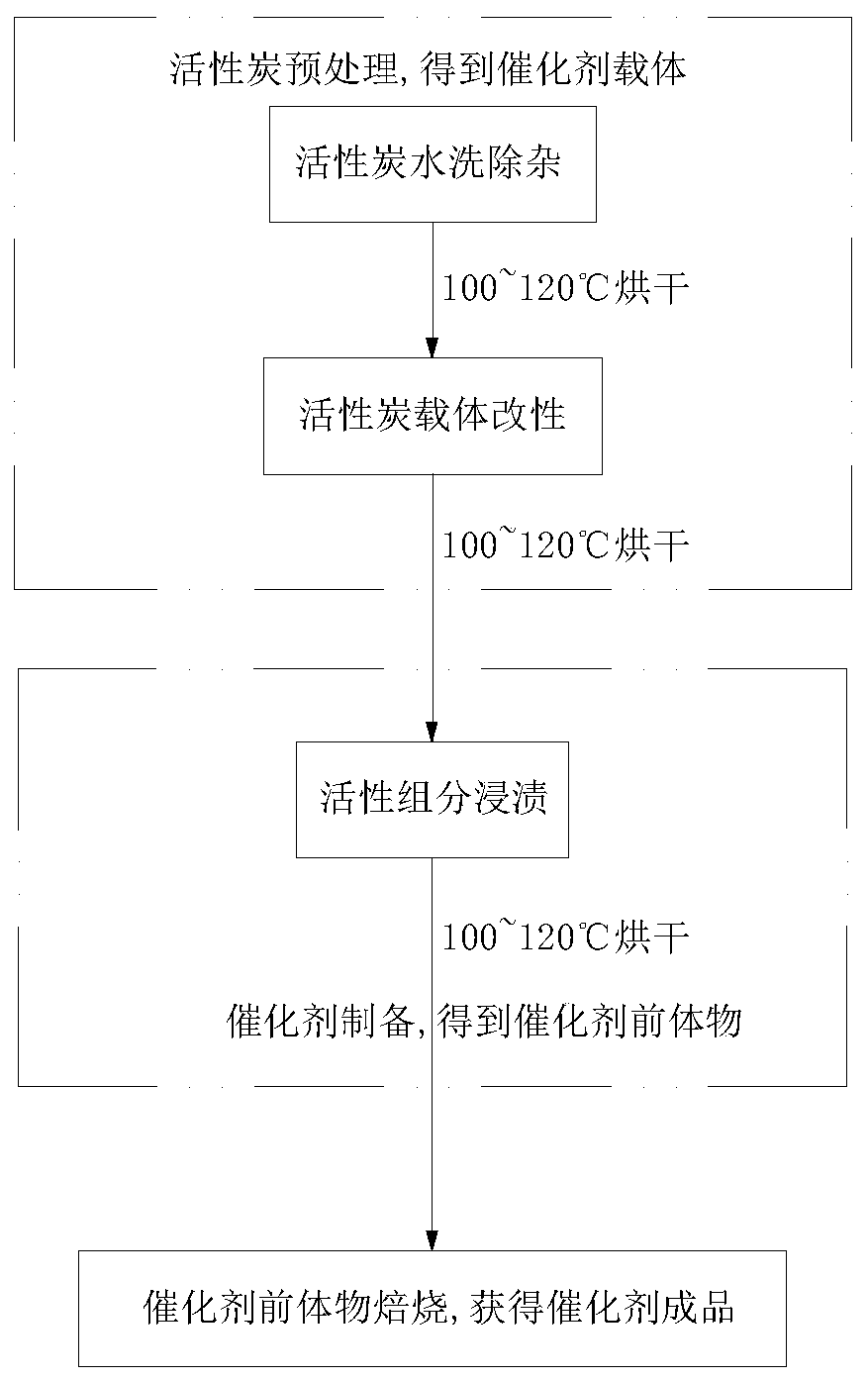

[0037] A kind of preparation method of ozone catalytic oxidation catalyst that preferred embodiment of the present invention provides, concrete steps are as follows:

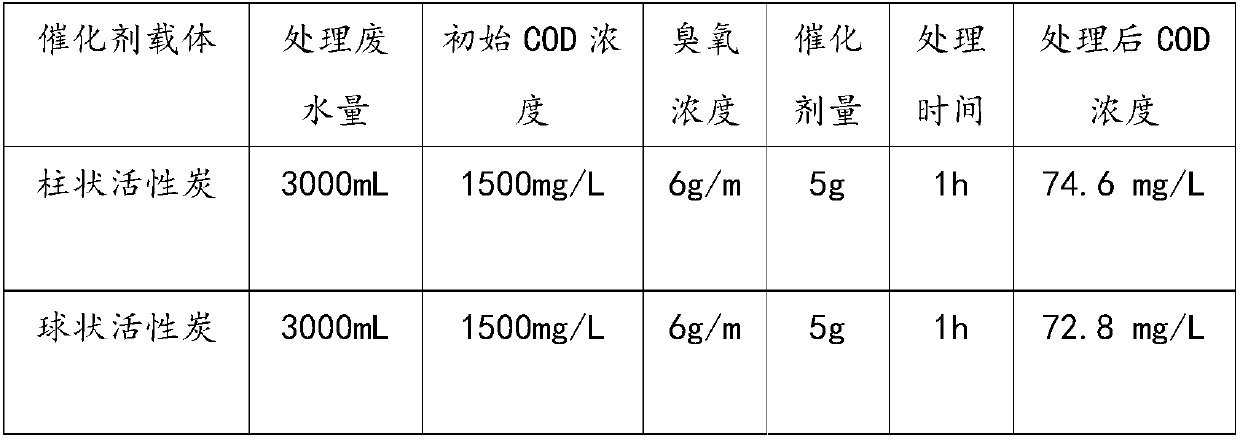

[0038] (1) Wash columnar granular activated carbon with a diameter of 3-5mm and a length of 1-2cm and spherical granular activated carbon with a diameter of 3-5mm to remove impurities in sequence, and place them in a 100°C oven for drying after cleaning to obtain two types of activated carbon. active particles;

[0039] (2) Add 1mol / L sodium hydroxide solution to the two types of active particles according to the ratio of 10g active particles: 50mL sodium hydroxide solution, stir and mix for 2 hours, soak for 6 hours, take out and wash with water until the pH value of the cleaning solution reaches 7. Place it in an oven and dry it at 100°C, and cool it at room temperature to obtain two types of pretreated activated carbon carriers;

[0040] (3) The two types of pretreated activated carbon carriers were impregna...

Embodiment 2

[0043] A kind of preparation method of ozone catalytic oxidation catalyst that preferred embodiment of the present invention provides, concrete steps are as follows:

[0044] (1) Wash the spherical granular activated carbon with a diameter of 3-5mm to remove impurities, place it in a 100°C oven for drying after cleaning, and obtain active particles;

[0045] (2) Add 1mol / L sodium hydroxide solution to the active granules according to the ratio of 10g active granules: 50mL sodium hydroxide solution, stir and mix for 3 hours, soak for 6 hours, take out and wash with water until the pH value of the cleaning solution reaches 6.5, and then place it in Dry in an oven at 100°C and cool at room temperature to obtain a pretreated activated carbon carrier;

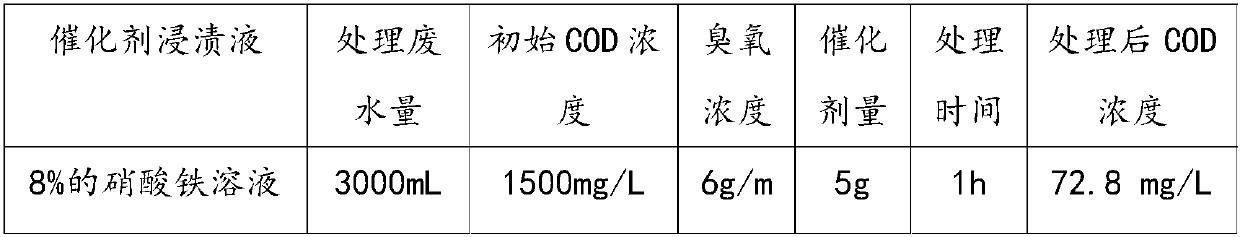

[0046] (3) impregnate the pretreated gac carrier with mass fraction of 8% ferric nitrate, 8% manganese nitrate, 8% ferric nitrate and manganese nitrate mixed solution, stir for 2h, let stand for 24h, take out the solid components an...

Embodiment 3

[0049] A kind of preparation method of ozone catalytic oxidation catalyst that preferred embodiment of the present invention provides, concrete steps are as follows:

[0050] (1) Wash the spherical granular activated carbon with a diameter of 3-5mm to remove impurities, place it in a 100°C oven for drying after cleaning, and obtain active particles;

[0051] (2) Add 1mol / L sodium hydroxide solution to the active granules according to the ratio of 10g active granules: 50mL sodium hydroxide solution, stir and mix for 3 hours, soak for 6 hours, take out and wash with water until the pH value of the cleaning solution reaches 6.5, and then place it in Dry in an oven at 100°C and cool at room temperature to obtain a pretreated activated carbon carrier;

[0052] (3) impregnating the pretreated activated carbon carrier with a ferric nitrate solution with a mass fraction of 8%, stirring for 2 hours, standing for 24 hours, taking out the solid component and putting it in an oven at 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com