High-fluidity ethylene-alpha-octene graft copolymer and preparation method thereof

A technology of graft copolymer and octene copolymer, which is applied in the field of modified polymer copolymer and its preparation, can solve the problems of low production cost, reduced fluidity, inconvenient large-scale production, etc., and achieve easy mixing and granulation , Good notched impact performance, short reaction residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

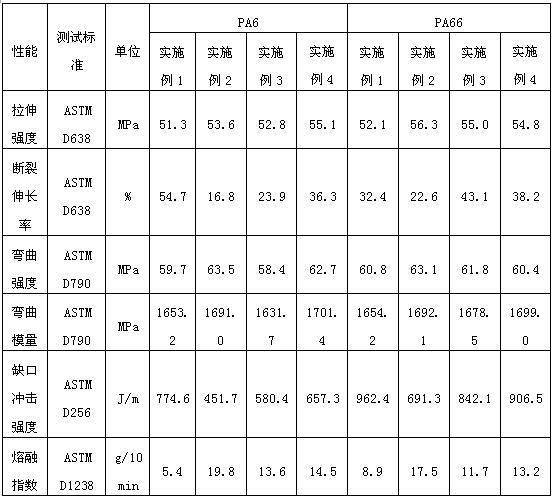

Examples

Embodiment 1

[0031] Weigh the following components according to parts by weight: 100 parts of POE resin (DOW, ENGAGE 8200, MI (melt index)=5.0g / 10min), 2 parts of maleic anhydride as the grafting monomer, and diisopropyl peroxide as the initiator 0.1 part of benzene, 0.3 part of stearate, 0.3 part of antioxidant, 0.2 part of wax oil.

[0032] Put the other components except the initiator into the high-speed mixer according to the proportion and mix for 5 minutes. After the main feed is metered, they are added to the twin-screw extruder. The initiator is metered through the side feed and then added to the extruder. , The temperature of each section of the extruder from the feeding port to the head is set between 100°C and 200°C, the screw speed is controlled at 300 rpm, the screw length to diameter ratio is 48:1, and the mixture is melted and plasticized , Kneading and mixing, extruding with head, drawing, cooling, pelletizing, drying to obtain products.

Embodiment 2

[0034] Weigh the following components according to parts by weight: 100 parts of POE resin (DOW, ENGAGE 8402, MI=30.0g / 10min), 3 parts of glycidyl methacrylate as the grafting monomer, and 2,5-dimethyl methacrylate as the initiator Base-2,5-di-tert-butyl hexane and dicumyl peroxide constitute 0.15 parts, PE wax 0.4 parts, 1010 and 168 are antioxidants 0.4 parts, and white oil is 0.1 parts.

[0035] Put the other components except the initiator into the high-speed mixer according to the proportion and mix for 8 minutes. After the main feed is metered, they are added to the twin-screw extruder. The initiator is metered through the side feed and then added to the extruder. , The temperature of each section of the extruder from the feeding port to the head is set between 80°C and 180°C, the screw speed is controlled at 400 rpm, the screw length to diameter ratio is 52:1, and the mixture is melted and plasticized , Kneading and mixing, extruding with head, drawing, cooling, pelletizin...

Embodiment 3

[0037] Weigh the following components according to parts by weight: 100 parts of POE resin (DOW, ENGAGE 8130 MI=13.0g / 10min), 3 parts of maleic anhydride and glycidyl methacrylate (1:2) as the grafting monomer, and start The agent is 0.2 parts of bis(tert-butylperoxyisopropyl)benzene, 0.4 parts of stearate, 0.4 parts of antioxidants for 1010 and 168, and 0.2 parts of white oil.

[0038] Put the other components except the initiator into the high-speed mixer according to the proportion and mix for 3 minutes. After the main feed is metered, they are added to the twin-screw extruder. The initiator is metered through the side feed and then added to the extruder. , The temperature of each section of the extruder from the feeding port to the head is set between 110°C and 220°C, the screw speed is controlled at 200 rpm, the screw length to diameter ratio is 36:1, and the mixture is melted and plasticized , Kneading and mixing, extruding with head, drawing, cooling, pelletizing, drying t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com